A kind of polycrystalline silicon ingot and its preparation method and polycrystalline silicon chip

A technology for polycrystalline silicon ingots and silicon materials, which is applied to the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, etc., can solve the problems of uneven crystal grains, low quality of polycrystalline silicon ingots, and disordered crystal orientations, so as to improve the photoelectric conversion efficiency. , The effect of reducing dislocation propagation and low dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing polycrystalline silicon ingots, including:

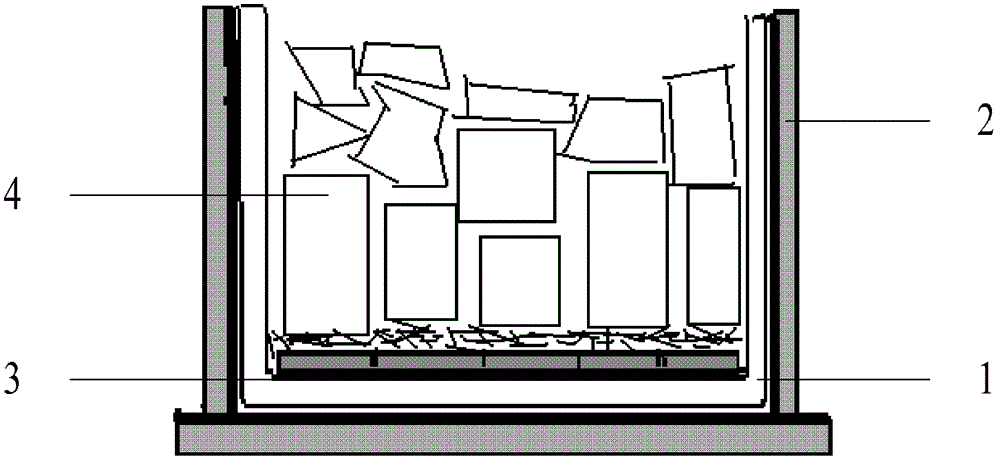

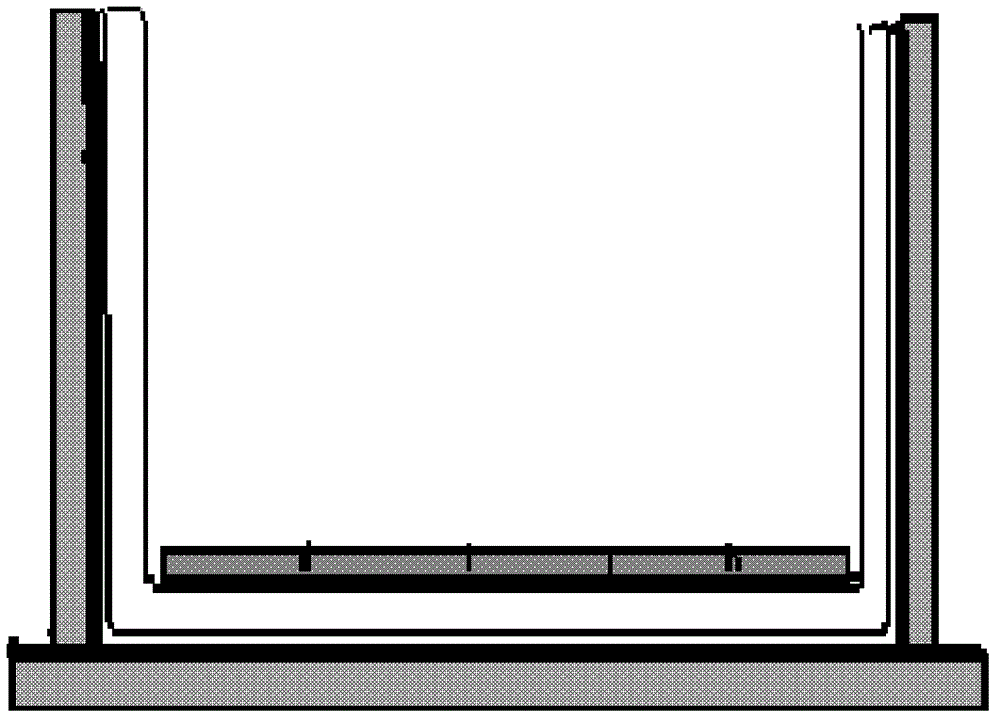

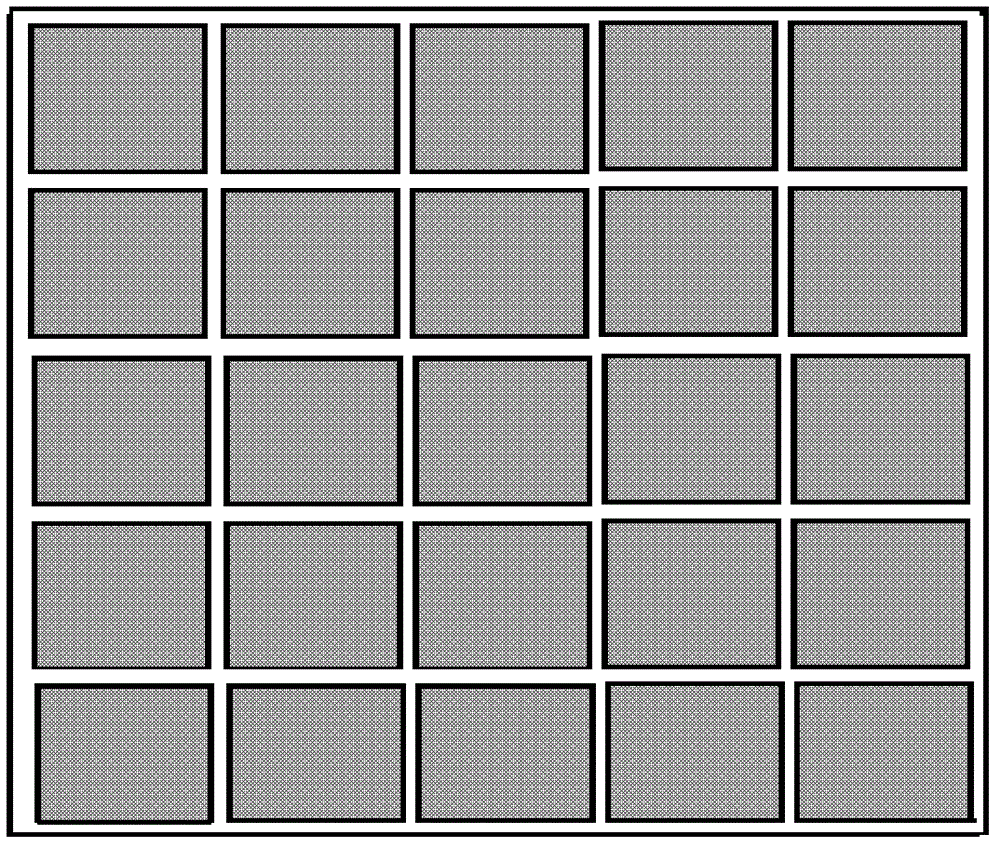

[0037] Using a quartz crucible, spray a layer of silicon nitride coating on the inner wall of the crucible. On the bottom of the crucible, 25 square silicon nitride porous materials with a size of 155mm×155mm were laid. After laying the foundation, fill the silicon nitride porous material with silicon material until it is completely filled. Figure 1~3 This is a schematic diagram of charging in this embodiment, figure 1 1 is a crucible, 2 is a graphite guard plate, 3 is a porous silicon nitride material, and 4 is a silicon material.

[0038] Put the above crucible containing silicon material into the ingot casting furnace, start the ingot casting program, evacuate, and then heat to the melting point temperature of silicon, and let the silicon material slowly melt to form a silicon melt. After the silicon material is completely melted, the heat insulation cage is slowly opened and the temperature is lowered...

Embodiment 2

[0044] A method for preparing polycrystalline silicon ingots, including:

[0045] Using a quartz crucible, spray a layer of silicon nitride coating on the inner wall of the crucible. At the bottom of the crucible, 25 square silicon carbide porous materials with a size of 155×155 mm were laid. After the laying is completed, the silicon carbide porous material is filled with silicon material until it is completely filled.

[0046] Put the above crucible containing silicon material into the ingot casting furnace, start the ingot casting program, evacuate, and then heat to the melting point temperature of silicon, and let the silicon material slowly melt to form a silicon melt. After the silicon material is completely melted, the heat insulation cage is slowly opened and the temperature is lowered, so that the temperature of the silicon melt is reduced to form a supercooled state, and nucleation and crystallization.

[0047] Wait until the directional solidification of the silicon ingo...

Embodiment 3

[0052] A method for preparing polycrystalline silicon ingots, including:

[0053] Using a quartz crucible, spray a layer of silicon nitride coating on the inner wall of the crucible. At the bottom of the crucible, 25 pieces of square quartz porous material with a size of 155×155mm were laid. After laying the foundation, fill the silica material on the porous quartz material until it is completely filled.

[0054] Put the above crucible containing silicon material into the ingot casting furnace, start the ingot casting program, evacuate, and then heat to the melting point temperature of silicon, and let the silicon material slowly melt to form a silicon melt. After the silicon material is completely melted, the heat insulation cage is slowly opened and the temperature is lowered, so that the temperature of the silicon melt is reduced to form a supercooled state, and nucleation and crystallization.

[0055] Wait until the directional solidification of the silicon ingot is complete. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com