Activated carbon printing coating or laminating fabric and preparation method thereof

A technology of activated carbon and printing layer, applied in the field of activated carbon printing coating or film-coated fabric and its preparation, to achieve the effect of super moisture absorption and quick drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

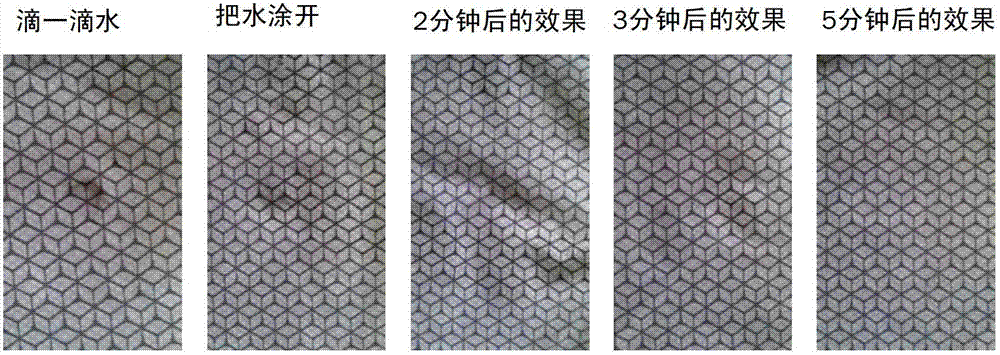

Image

Examples

Embodiment 1

[0041] a) Choose 20D DTY nylon fabric as the base fabric, use German Rudolph ECO fluorine-free waterproofing agent for waterproof treatment, and use wet microporous coating technology to coat the back of the base fabric. The processing temperature is 170 °C, and the coating The raw material is Japanese DIC resin.

[0042] Configure printing layer raw materials; described printing layer raw materials include: quality is 22 parts of polyurethane, quality is 8 parts of bridging agent containing coconut shell activated carbon powder, quality is 20 parts of N, N dimethyl formamide, 20 parts toluene and 30 parts of methyl ethyl ketone; for printing, the equipment is a printing machine (Kunshan Xiecheng Machinery Manufacturing Factory), the printing temperature is 120°C, and the speed is 20m / min.

[0043] Baking; the equipment is a printing machine (Kunshan Xiecheng Machinery Manufacturing Factory), the temperature is 120°C, and the speed is 20m / min.

[0044] Cool the rolls.

Embodiment 2

[0046] Choose 40D DTY nylon fabric as the base fabric, use German Rudolf ECO fluorine-free waterproofing agent for waterproof treatment, use wet microporous coating technology to coat the back of the base fabric, the processing temperature is 160 ° C, and the coating material is Japanese DIC resin.

[0047] Configure the printing layer raw materials; the printing layer raw materials include: 10 parts of polyurethane by quality, 12 parts of bridging agent containing woody activated carbon powder, 1 part of antibacterial capsule, 20 parts of N,N dimethyl Formamide, 20 parts of toluene and 30 parts of methyl ethyl ketone; printing, the equipment is a printing machine (Kunshan Xiecheng Machinery Manufacturing Factory), the printing temperature is 140°C, and the speed is 20m / min.

[0048] Baking; the equipment is a printing machine (Kunshan Xiecheng Machinery Manufacturing Factory), the temperature is 140°C, and the speed is 20m / min.

[0049] cool down.

[0050] Lay conventional ...

Embodiment 3

[0052] Choose 40D DTY nylon fabric as the base fabric, use German Rudolf ECO fluorine-free waterproofing agent for waterproof treatment, use microporous coating technology to coat the back of the base fabric, the processing temperature is 160°C, and the coating material is Japanese DIC resin.

[0053]Configure the printing layer raw materials; the printing layer raw materials include: a quality of 8 parts of polyurethane, a quality of 15 parts of bridging agent containing bamboo activated carbon powder, 2 parts of aromatic capsules, a quality of 20 parts of N,N dimethyl Formamide, 20 parts of toluene and 30 parts of methyl ethyl ketone; printing, the equipment is a printing machine (Kunshan Xiecheng Machinery Manufacturing Factory), the printing temperature is 140°C, and the speed is 20m / min.

[0054] Baking; the equipment is a printing machine (Kunshan Xiecheng Machinery Manufacturing Factory), the temperature is 140°C, and the speed is 20m / min.

[0055] Cool the rolls.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com