Two-stroke diesel engine

A diesel engine, two-stroke technology, applied in mechanical equipment, engine components, engine control, etc., can solve the problems of inefficiency, increased wear, and high fuel consumption, and achieve the effects of reducing replacement and use costs, reducing resistance, and reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

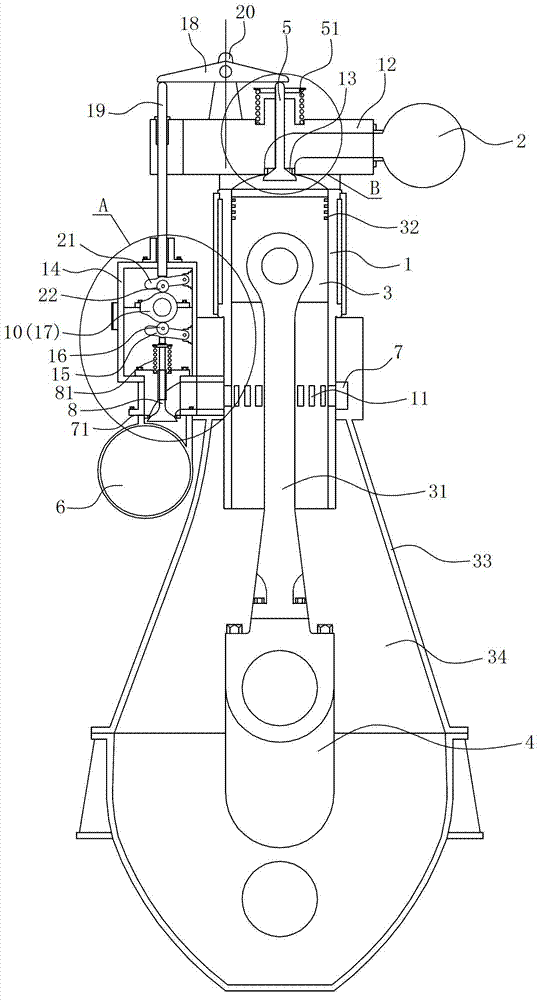

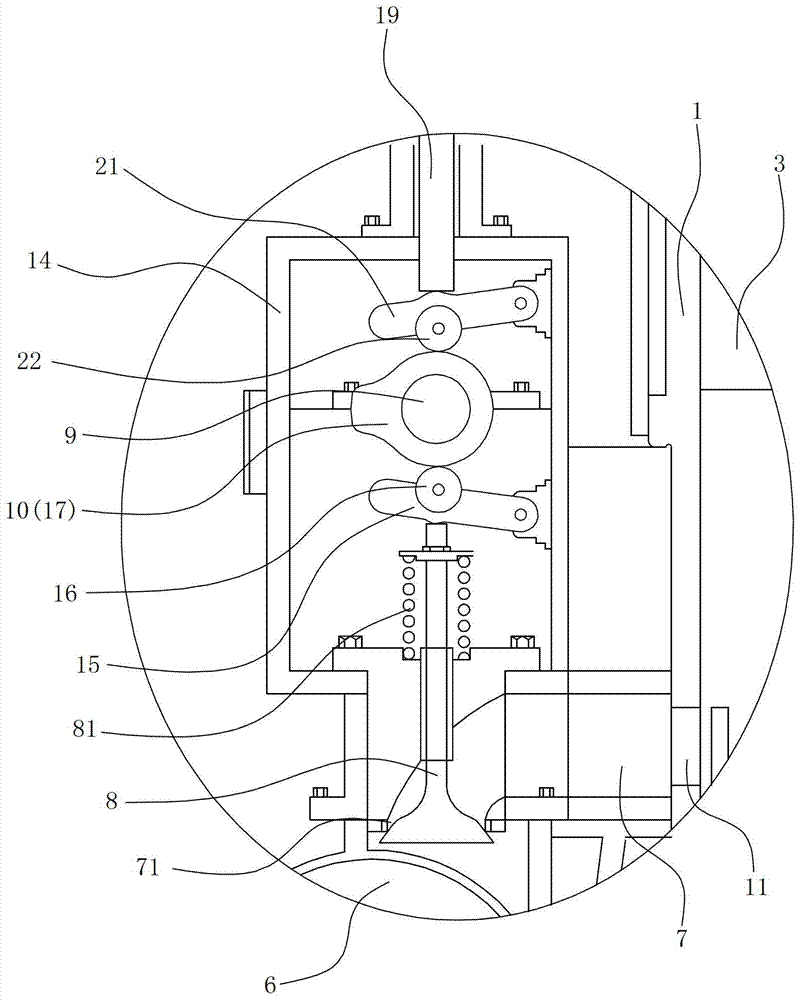

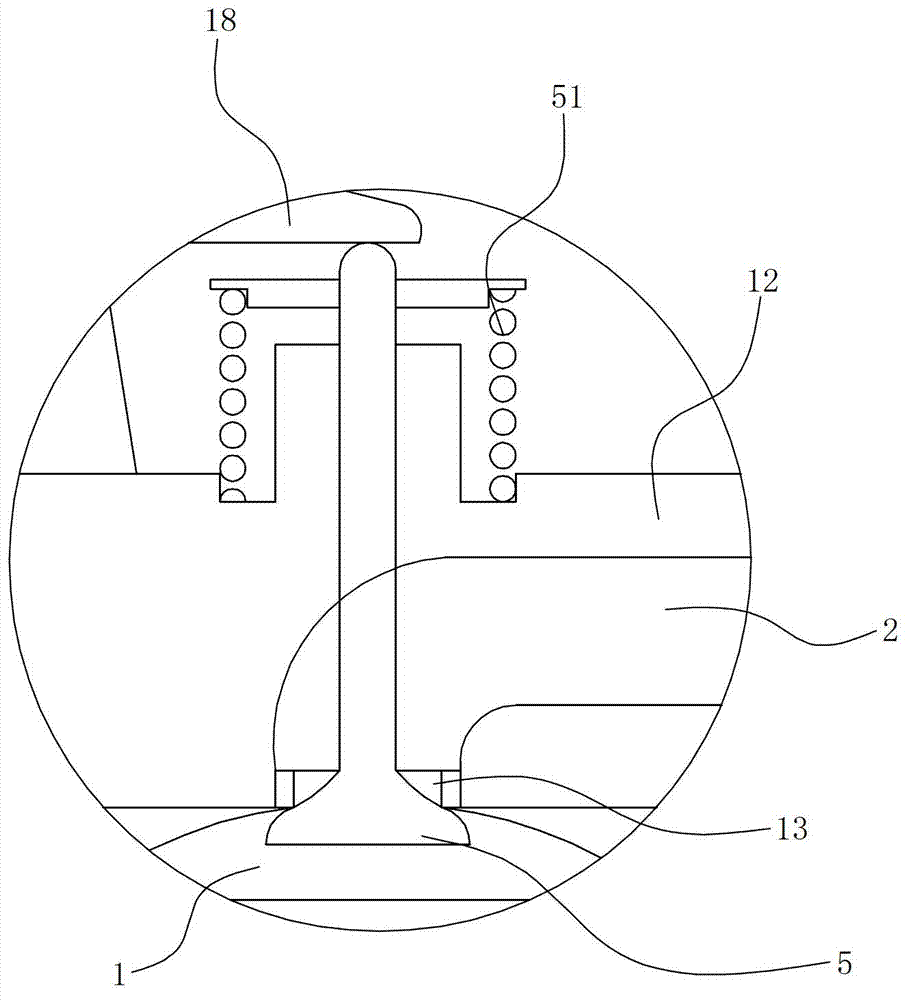

[0034] like Figure 1~5 Shown is a preferred embodiment of the present invention.

[0035] A two-stroke diesel engine includes a frame 33, a cylinder liner 1, a cylinder head 12, an exhaust pipe 2, a crankshaft 4, an oil injector 28, a fuel valve 29, a high-pressure oil pump 30, and the like. Wherein, the cylinder liner is provided with a piston 3 that can move up and down, and the piston 3 is connected with the crankshaft 4 through the connecting rod 31. In the example, there are four piston rings 32. Of course, there may be more than one piston ring 32. At the same time, the distance between the uppermost piston ring and the lowermost piston ring is greater than the height of the air inlet 11 described below. The lubrication of the piston rings 32 requires oil injection. Device 28 provides. The cylinder head 12 at the top of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com