Universal LED bulb formation method and liquid fluorescent LED bulb

A kind of LED light bulb, a general-purpose technology, applied in the field of LED lighting, can solve the problems of LED lighting products such as hard damage, difficult maintenance, inconvenient use, etc., and achieve the effects of reducing LED light decay, simple and reliable structure, and avoiding local high heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

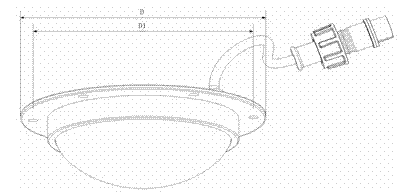

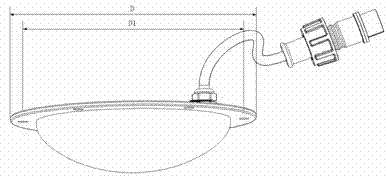

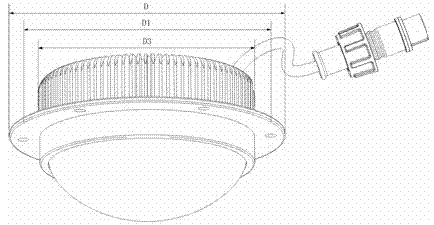

[0063] Example. General-purpose LED light bulb composition method: by bonding an optical-mechanical module on a metal heat-conducting bracket, surrounding the optical-mechanical module with a ring-shaped non-metallic bracket lining, and fixing the bracket lining on the heat-conducting bracket to conduct heat The bracket and the bracket lining are the center of the bulb structure to install the bulb parts to form the LED bulb, so that the structure between the optical-mechanical module and the heat-conducting bracket is simple and reliable, which is beneficial to the heat dissipation of the LED. The optomechanical module is composed of optomechanical templates, LED chipsets and related circuits through die bonding and packaging, or a power supply driver chip is also integrated therein. The optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com