High-frequency detection pulse injection method of brushless direct current motor

A brushed DC motor, high-frequency detection technology, applied in electronic commutation motor control, single motor speed/torque control, electrical components and other directions, can solve problems such as increasing system cost, motor speed deviation, limiting detection accuracy, etc. Improve accuracy and timeliness, improve low-speed and zero-speed performance, and expand the effect of inductance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawings and examples.

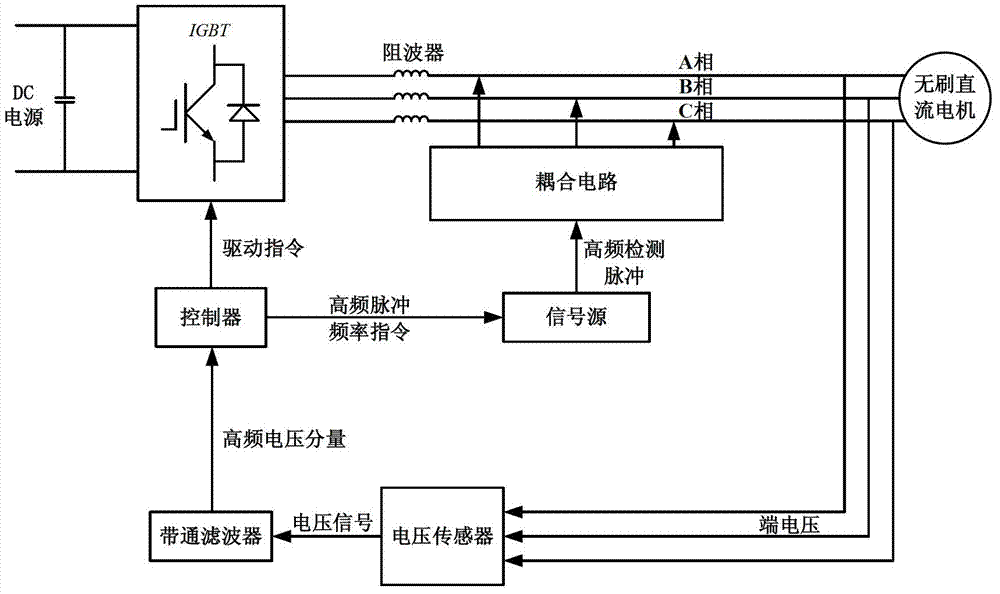

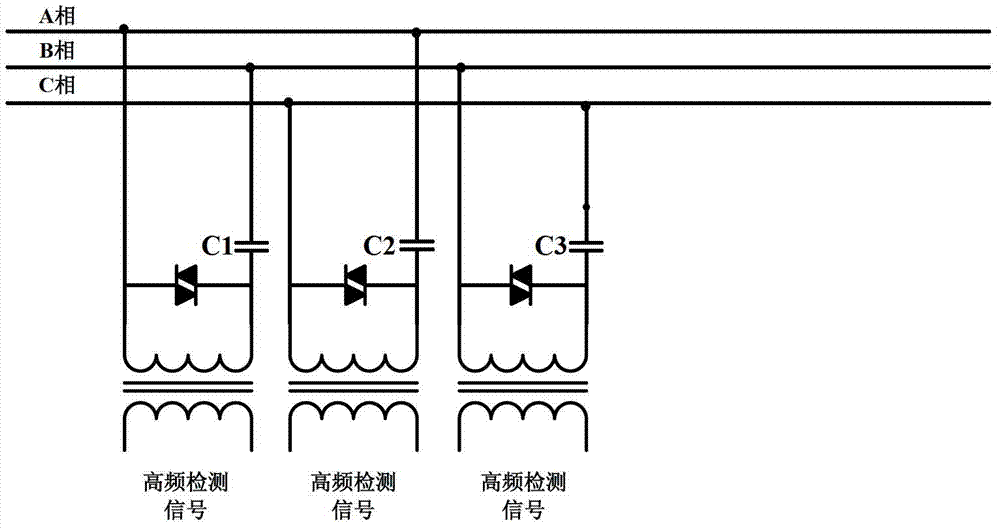

[0021] The principle diagram of the present invention is as figure 1 As shown, the controller, brushless DC motor and power switch are the same as the common brushless DC motor drive system. It can be seen from the figure that there is a set of independent high-frequency detection pulse injection mechanism deployed on the output side of the power switch. The high-frequency detection pulse injection mechanism is composed of a signal source and a coupling circuit. Directly according to the high-frequency signal frequency command of the controller or generated by the signal source in the form of a fixed frequency, the high-frequency signal generated by the signal source is directly transmitted to the power line of the brushless DC motor through the coupling circuit.

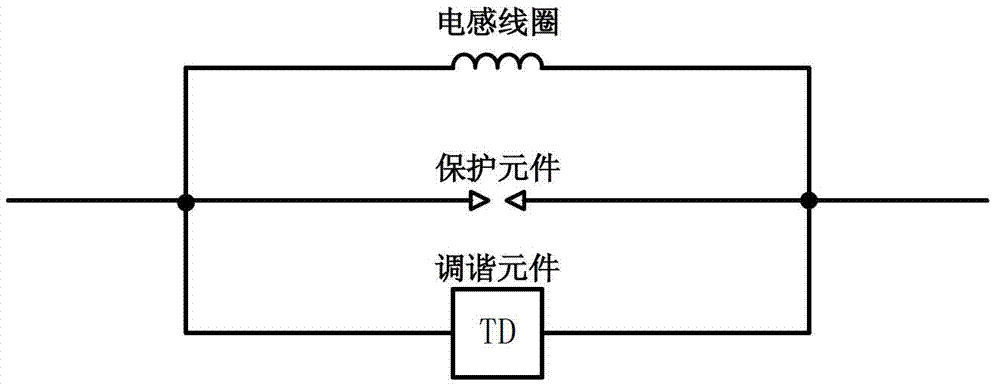

[0022] There is a high-frequency signal blocker between the high-frequency pulse injection poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com