Pulsed X-ray generation method and pulsed X-ray generation device

A generation method and X-ray technology, applied in the field of X-ray, can solve the problems of random jitter of switching level, unstable time base, short life of gate control tube, etc. Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

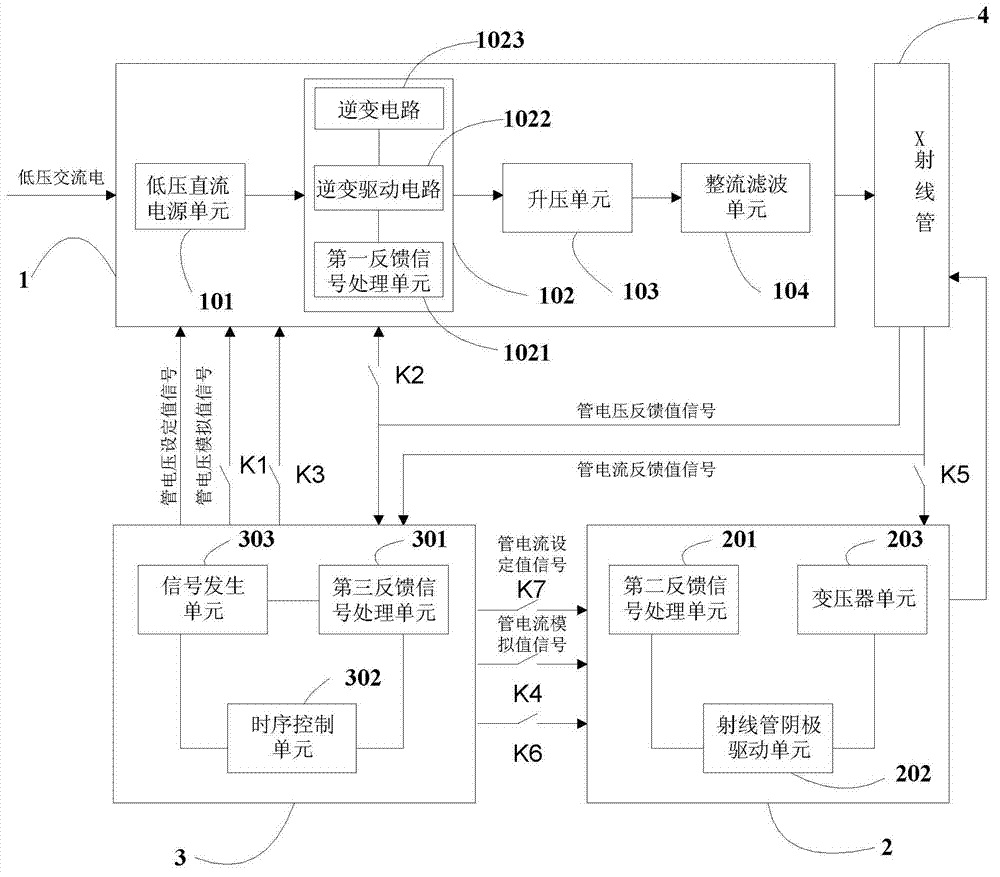

[0023] The invention provides a pulsed X-ray generating device, figure 1 It is a structural diagram of an embodiment of the present invention. The pulsed X-ray generating device of this embodiment includes a high-voltage pulse generating system 1 , a tube current control system 2 , a control system 3 and an X-ray tube 4 .

[0024] Among them, the high-voltage pulse generation system 1 is used to generate a high-voltage pulse voltage to be applied to both ends of the X-ray tube, the tube current control system 2 is used to provide the tube current of the X-ray tube 4, and the control system 3 is connected with the high-voltage pulse generation system 1 respectively. 1. The ray tube current control system 2 is connected with the X-ray tube 4 to control the work of the whole circuit.

[0025]The high-voltage pulse generation system 1 includes a low-voltage DC power supply unit 101, an inverter unit 102, a boost unit 103, and a rectification and filtering unit 104 connected in seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com