Disk-milling main shaft device of vane-integrated disk numerical control machine tool

A technology of CNC machine tools and integral blisks, which can be used in driving devices, metal processing mechanical parts, metal processing equipment, etc., and can solve the problems of low production efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

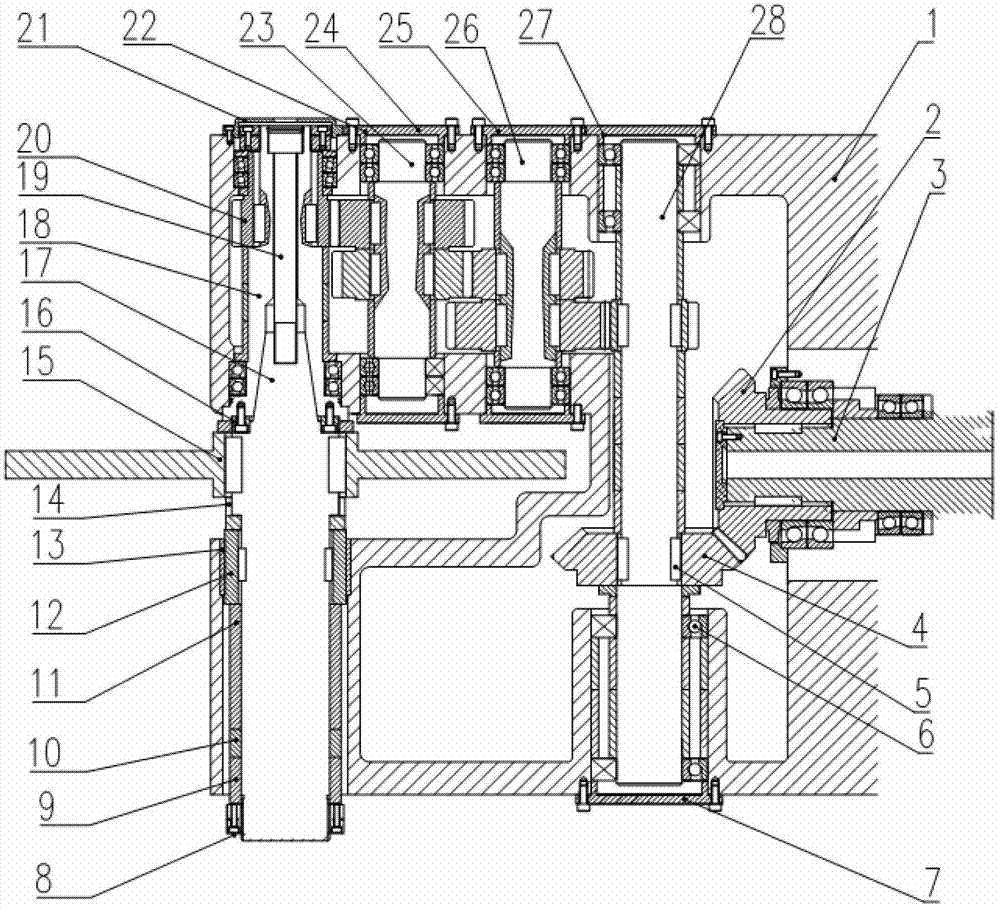

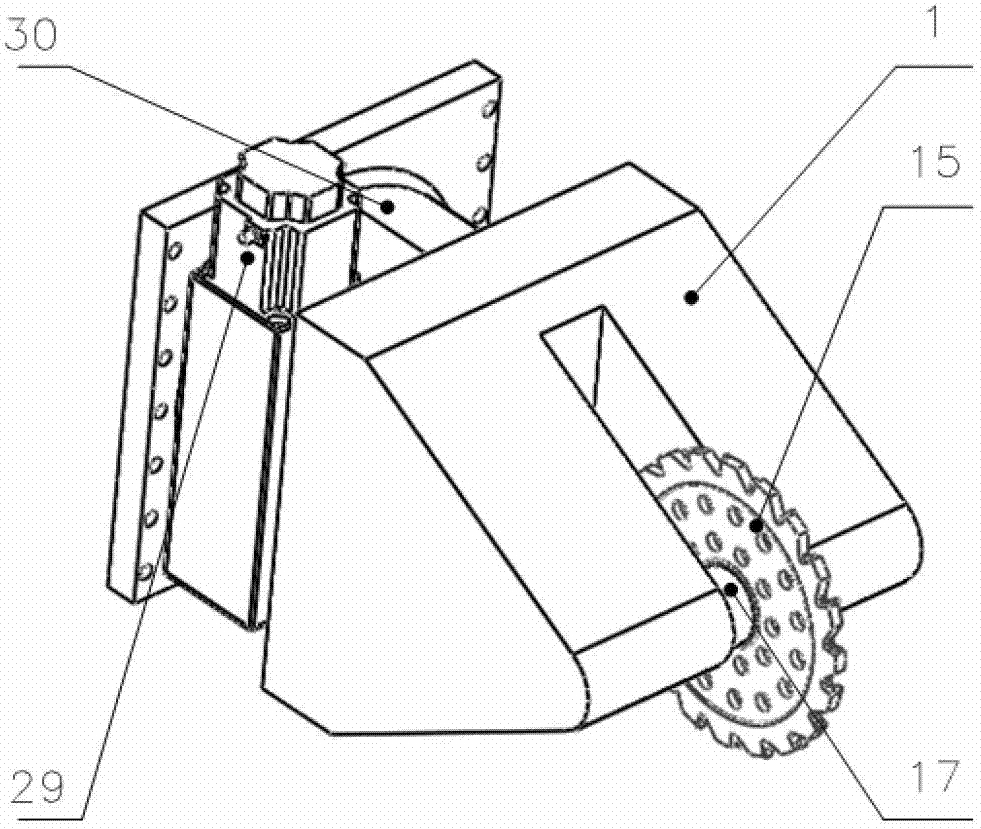

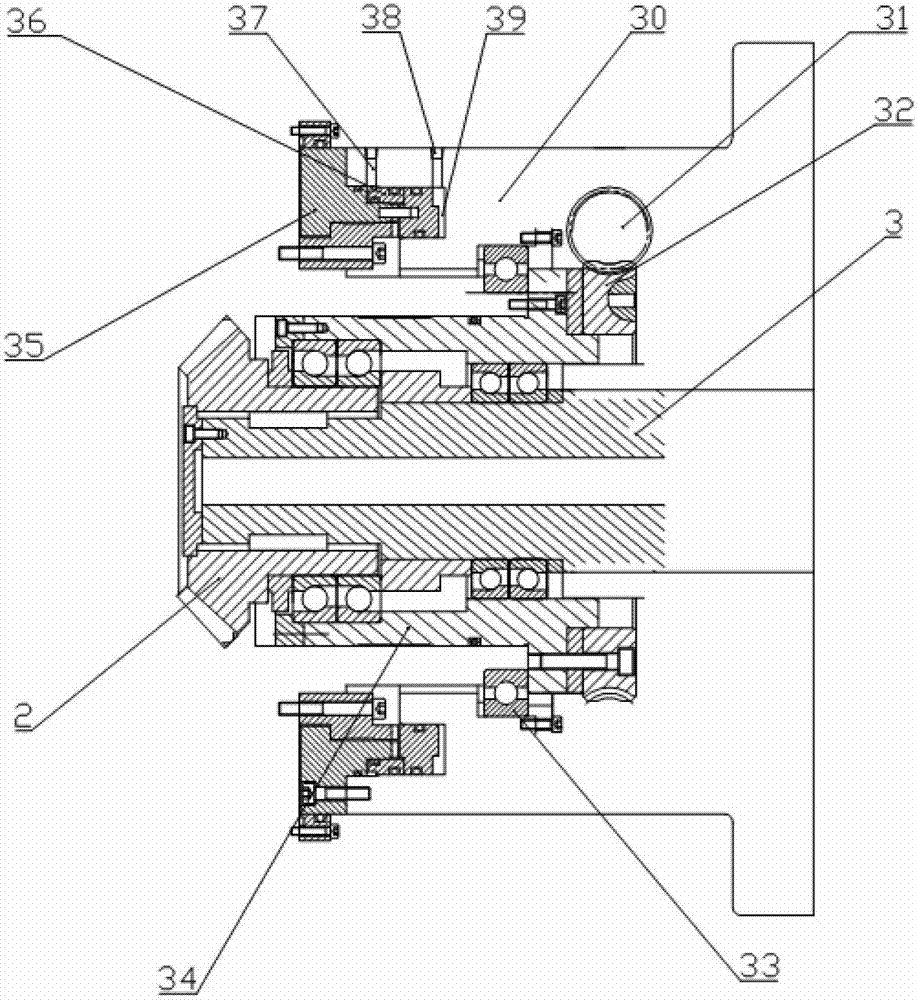

[0020] This embodiment is a disc milling spindle device with the characteristics of high rigidity, high torque, and large cutting force for a numerically controlled machine tool.

[0021] refer to figure 1 , figure 2 , image 3 , the disc milling spindle device of the integral blisk numerical control machine tool of the present invention is composed of a disc milling headstock, a disc milling cutter assembly, a power transmission mechanism, a rattle disc, and a turbine worm pair, including a disc milling headstock 1, a first bevel gear 2, First gear shaft 3, second bevel gear 4, first bushing 5, second bearing 6, first end cover 7, lock nut 8, second bushing 9, third bushing 10, fourth bushing 11. Cutter shaft sleeve 12, bearing bush 13, collar 14, disc milling cutter 15, bump 16, disc milling cutter shaft 17, second gear shaft 18, pull nail 19, helical cylindrical gear 20, second end cover 21. Third end cover 22, third gear shaft 23, fourth end cover 24, fifth end cover 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com