Energy-saving environmentally-friendly converter slag splashing protecting charging and production process thereof

An energy-saving and environmental protection technology, slag splashing furnace protection technology, applied in the field of refractory materials, can solve the problems of consumption of light-burned magnesium powder raw material resources, difficult control of viscosity, and no increase in melting point, etc., to improve the condition of the converter lining, lower production costs, and extend service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

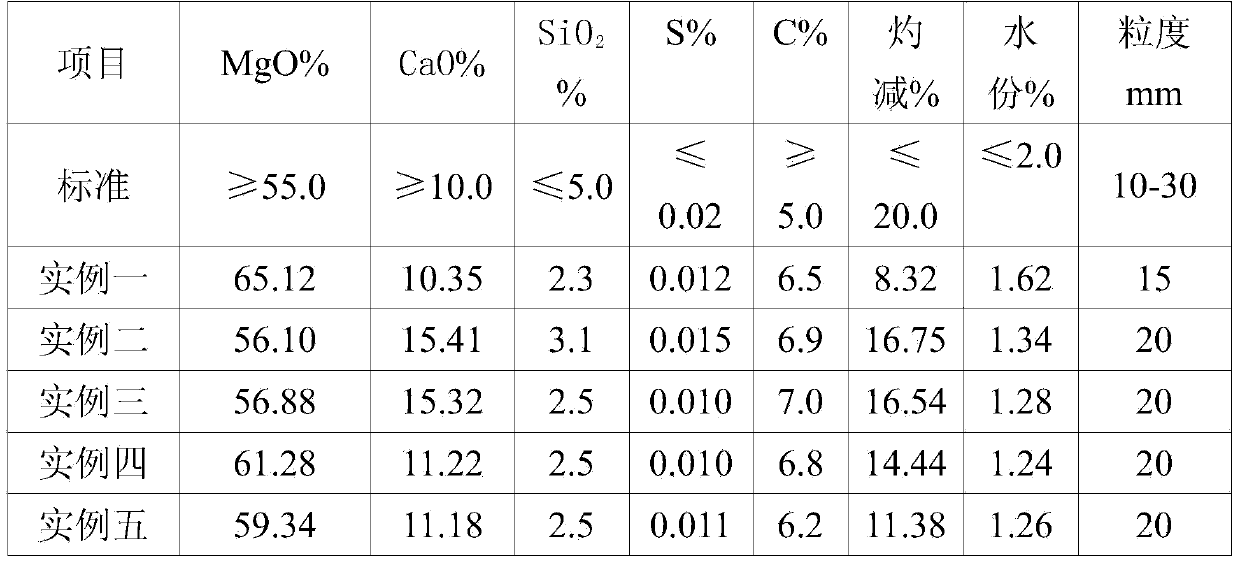

example 1

[0029] Example 1: The proportions of various raw materials are as follows: 35 of light-burned magnesia powder, 50 of waste magnesia-carbon bricks of the converter after use, 10 of limestone, and 5 of active lime dust removal powder. This case has the lowest cost, but the pelleting effect is poor, the pelletizing particle size is small, and the yield is low.

example 2

[0030] Example 2: The proportions of various raw materials are as follows: 40 light-burned magnesia powder, 30 waste magnesia carbon bricks from the converter after use, 23 limestone, 2 coke, and 5 active lime dust removal powder. The cost of this example is low, the production is easy to control, and the use effect is good.

example 3

[0031] Example 3: The proportions of various raw materials are as follows: light-burned magnesia powder 45, waste magnesia-carbon bricks of post-conversion converter 25, limestone 24, coke 3, and active lime dust-removing powder 3. This case is expensive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com