Polytetrafluoroethylene fiber screen cloth and manufacture method of polytetrafluoroethylene fiber screen cloth

A technology of polytetrafluoroethylene and fiber mesh, which is applied in fiber treatment, chemical instruments and methods, textiles, etc., can solve the problems of over-thickness of the filling layer, chemical degradation and damage of the membrane, easy penetration, etc., and achieve high dimensional stability, Good proton passing performance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

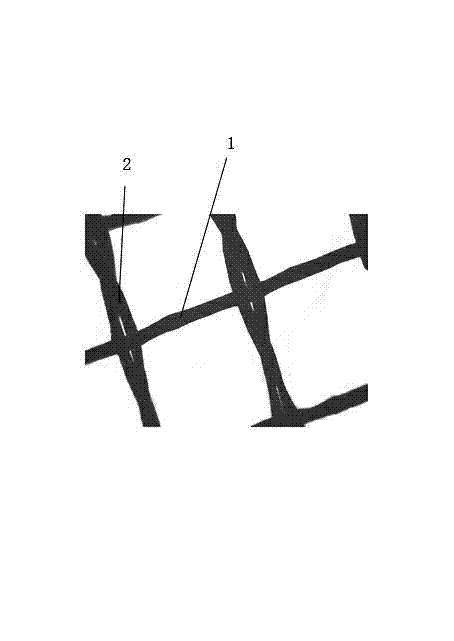

[0023] Such as figure 1 As shown, a polytetrafluoroethylene fiber mesh cloth, the mesh cloth is woven from polytetrafluoroethylene fibers as warp and latitude threads, and the mesh cloth is a warp and two weft structure, and the weft thread 2 is based on the warp thread 1 staggered. The mesh of the mesh is square, and the density of the mesh is 10 mesh / cm. The warp and weft of the mesh cloth are monofilament twisted, and the twist is 700 twists / m. The weft fiber width of the mesh cloth is 220 μm, and the warp fiber width is 130 μm. The fineness of the warp fiber and weft fiber is The degree is 100 denier. The monofilament strength of the warp and weft fibers of the mesh cloth is 4.1CN / dtex.

[0024] A method for making a polytetrafluoroethylene fiber mesh cloth, the mesh cloth is made by cutting a stretched polytetrafluoroethylene film into filaments, then twisting into threads, and then weaving , characterized in that: the cutting step is to shred the polytetrafluoroethyl...

Embodiment 2

[0027] Such as figure 1 As shown, a polytetrafluoroethylene fiber mesh cloth, the mesh cloth is woven from polytetrafluoroethylene fibers as warp and latitude threads, and the mesh cloth is a warp and two weft structure, and the weft thread 2 is based on the warp thread 1 staggered. The mesh of the mesh is square, and the density of the mesh is 10 mesh / cm. The warp and weft of the mesh cloth are monofilament twisted, and the twist is 750 twists / m. The weft fiber width of the mesh cloth is 220 μm, and the warp fiber width is 130 μm. The fineness of the warp fiber and weft fiber is The degree is 95 denier. The monofilament strength of the warp and weft fibers of the mesh cloth is 4.3CN / dtex.

[0028]A method for making a polytetrafluoroethylene fiber mesh cloth, the mesh cloth is made by cutting a stretched polytetrafluoroethylene film into filaments, then twisting into threads, and then weaving , characterized in that: the cutting step is to cut the polytetrafluoroethylene ...

Embodiment 3

[0031] Such as figure 1 As shown, a polytetrafluoroethylene fiber mesh cloth, the mesh cloth is woven from polytetrafluoroethylene fibers as warp and latitude threads, and the mesh cloth is a warp and two weft structure, and the weft thread 2 is based on the warp thread 1 staggered. The mesh of the mesh cloth is square, and the density of the mesh cloth is 10.5 mesh / cm. The warp and weft of the mesh cloth are monofilament twisted, and the twist is 800 twists / m. The weft fiber width of the mesh cloth is 225 μm, and the warp fiber width is 135 μm. The degree is 90 denier. The monofilament strength of the warp and weft fibers of the mesh cloth is 4.4CN / dtex.

[0032] A method for making a polytetrafluoroethylene fiber mesh cloth, the mesh cloth is made by cutting a stretched polytetrafluoroethylene film into filaments, then twisting into threads, and then weaving , characterized in that: the cutting step is to shred the polytetrafluoroethylene stretched film, stretch it while...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com