Fluid pump with screw spiral mechanism, fluid power machine and internal and external combustion jet engine

A technology of jet engine and power engine, applied in liquid fuel engine, internal combustion piston engine, rotary or oscillating piston engine, etc., can solve the problems of gap leakage, small compression and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

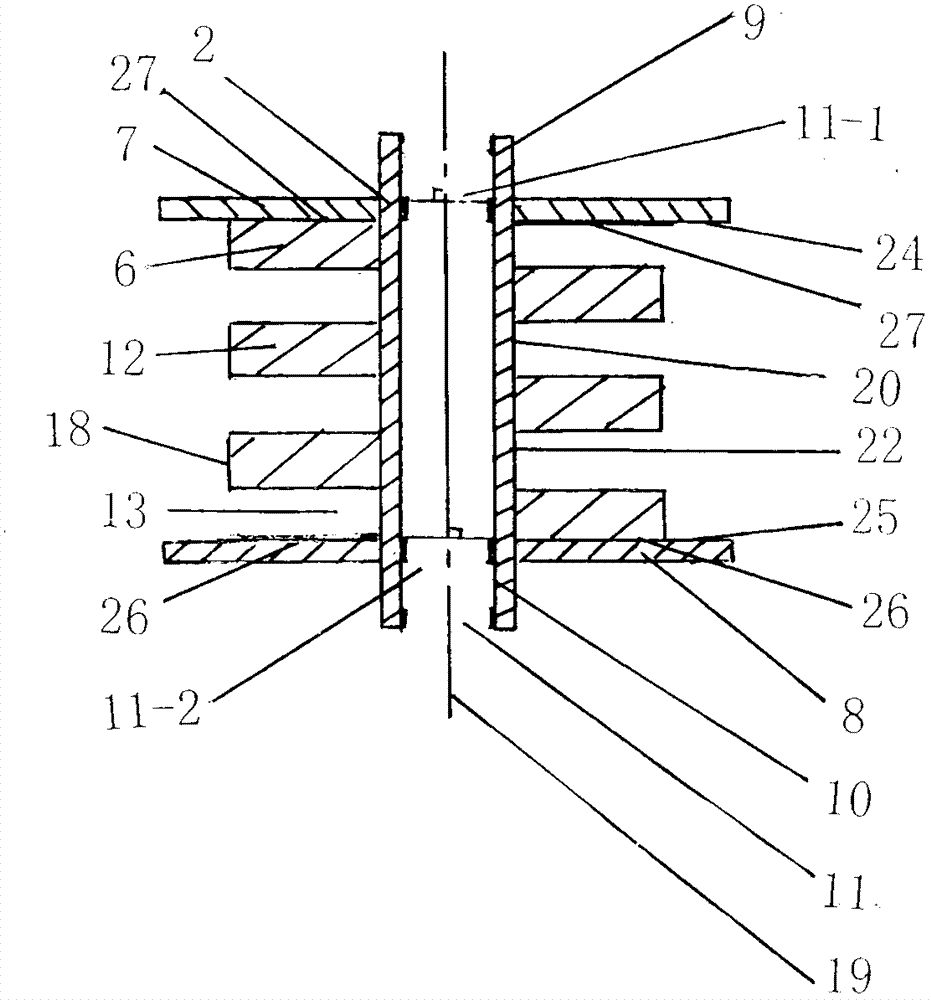

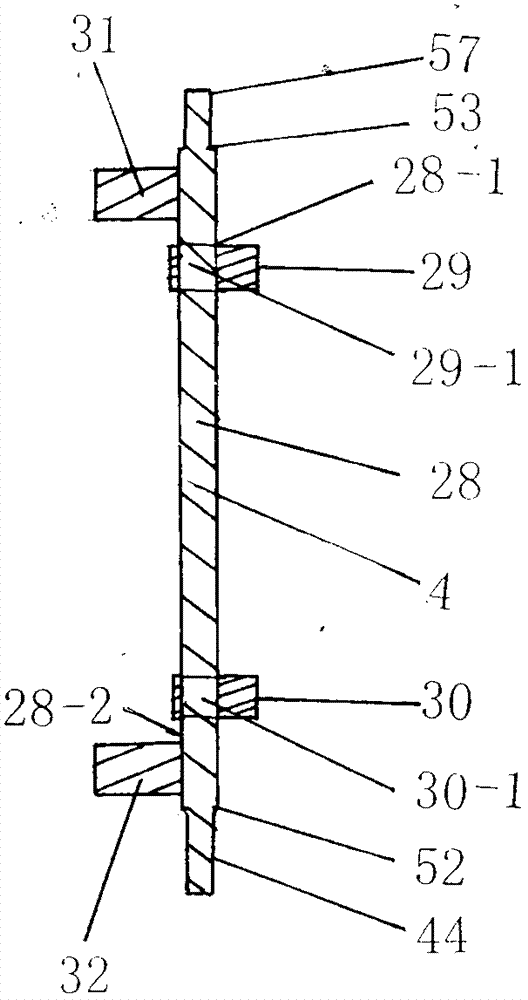

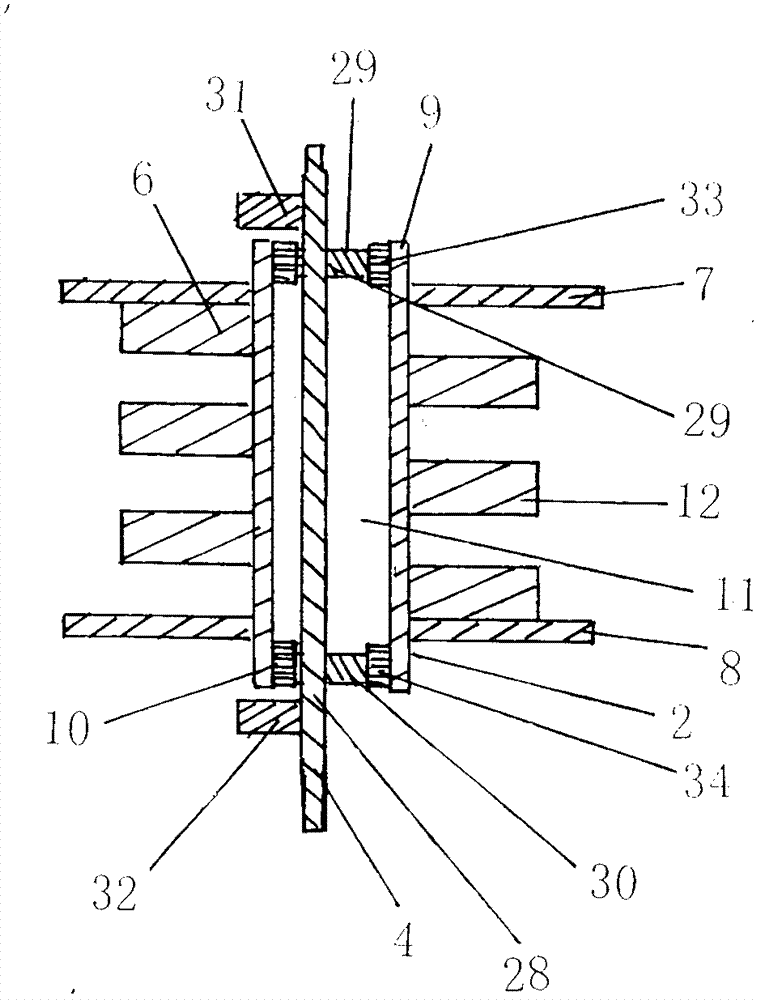

[0038] Screw and worm mechanism of the present invention 1 such as Figure 5 As shown, it is composed of a revolving screw body 2, an eccentric transmission member 4, a volute casing 3, an upper anti-rotation mechanism 5 and a lower anti-rotation mechanism 5-1. Such as figure 1 As shown, the revolving screw body 2 is composed of a screw rod 6, an upper moving plate 7, a lower moving plate 8, an upper shaft housing 9 and a lower shaft housing 10; as figure 1 As shown, the rod core 21 of the screw rod 6 has a hollow portion 11, the upper end 11-1 of the hollow portion 11 of the rod core 21 is fixed with the upper shaft shell 9, and the lower end 11-2 is fixed with the lower shaft shell 10, the rod core of the screw rod 6 The outer wall surface 22 of 21 has the helix 12 surrounded by the clockwise or counterclockwise direction helical line, the outer wall surface 22 top of the rod core 21 is fixed with the upper moving plate 7, the lower translation surface 24 of the upper movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com