Sucking disc type bench drill

A suction cup type and bench drill technology, which is applied to portable drilling machines, drilling/drilling equipment, parts of boring machines/drilling machines, etc., can solve the problems of not satisfying the magnet base, etc., and achieve convenient use and operation, easy production and manufacturing, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

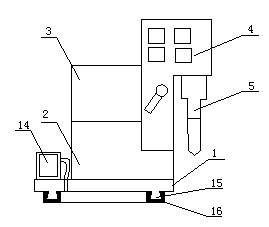

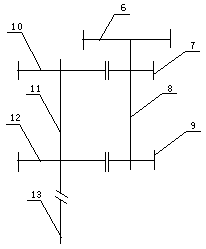

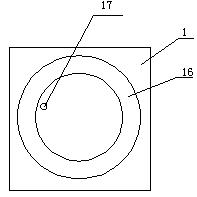

[0012] The support plate back side of the support is provided with a flange ring 15, and the section of the flange ring is trapezoidal. The sealing ring 16 is provided with a groove matching the flange ring, the sealing ring is connected on the flange ring through the groove, and the base plate is provided with a through hole 17, and the vacuum tube of the vacuum pump is connected to the through hole on the base plate. A fixed frame 2 is installed on the frame 1, and a motor 3, a transmission mechanism 4, a control circuit, an automatic feed mechanism and a stroke control switch are installed on the frame, and the rotor shaft of the motor is connected to the main shaft 13 through an automatic feed mechanism. , The travel control switch is connected to the control circuit. The input gear 6, the feed gear 9, and the transmission gear 7 are arranged on the spline shaft, the transmission gear and the spline shaft are slidably connected, and the feed gear is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com