Anti-static release liner as well as preparation method and equipment thereof

A base film and conductive polymer technology, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of hard and brittle films, incomplete curing, affecting texture, etc., and achieve less waste, Low cost and stable anti-static ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation of embodiment 1 antistatic release film

[0062] 1. Preparation of slurry

[0063]

[0064] Mix the above raw materials in order and stir for 30mim to form a uniformly mixed slurry.

[0065] 2. Preparation of antistatic release film

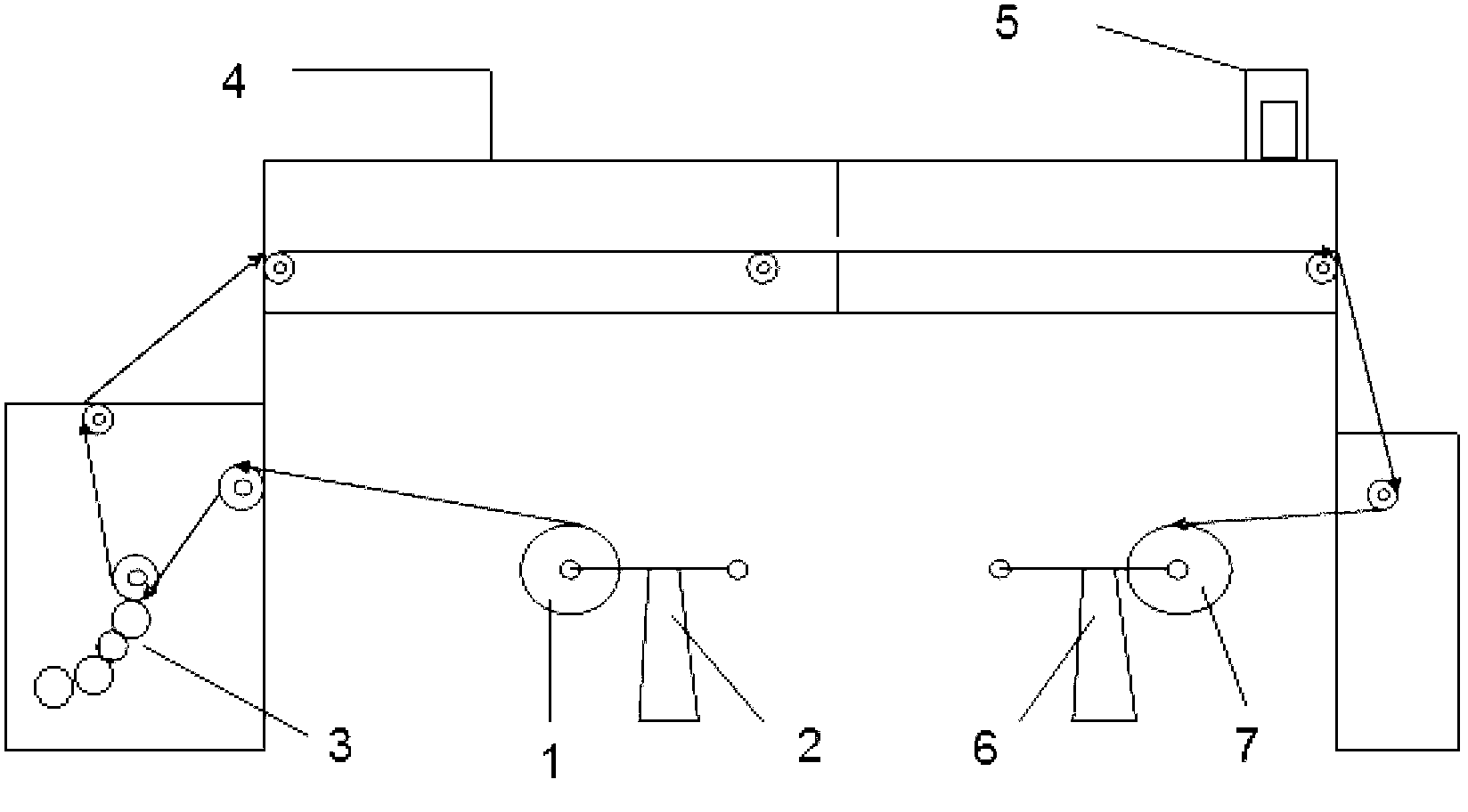

[0066] 1) Wrap the PET base film on the unwinding device 2, and the PET base film passes through the coating device 3 through the transmission wheel;

[0067] 2) Put the prepared slurry between the rollers 8 and 9, transfer the paint to the roller 10 by extrusion, the rollers 10 and 11 squeeze each other, transfer the roller 11, and apply the paint on the surface of the PET base film 1 , coating thickness 0.5μm;

[0068] 3) The coated PET base film enters the oven 4 through the transmission wheel for thermal curing, the curing temperature is 80 degrees, and the curing time is 10 seconds, then enters the UV curing box 5, turns on the air knife, and nitrogen rushes into the UV curing box 5 for light curing. UV intensity ...

Embodiment 2

[0070] The preparation of embodiment 2 antistatic release film

[0071] 1. Preparation of slurry

[0072]

[0073]

[0074] The preparation method is the same as in Example 1.

[0075] 2. Preparation of antistatic release film

[0076] 1) Wrap the PE base film on the unwinding device 2, and pass the PE base film through the coating device 3 through the transmission wheel;

[0077] 2) Put the configured slurry between the rollers 8 and 9, transfer the paint to the roller 10 by extrusion, the rollers 10, 11 squeeze each other, transfer the roller 11, and coat the slurry on the PE base film 1 Surface, coating thickness 2μm;

[0078] 3) The coated PE base film enters the oven 4 through the transmission wheel for thermal curing, the curing temperature is 120 degrees, and the curing time is 30 seconds, then enters the UV curing box 5, turns on the air knife, and nitrogen rushes into the UV curing box 5 for light curing. UV intensity is 120W, dose is 100J / cm 2 , Irradiatio...

Embodiment 3

[0080] The performance detection of embodiment 3 antistatic release film

[0081] 1. Anti-static test

[0082] Testing equipment: surface resistance tester

[0083] Temperature: 22℃±5℃

[0084] Humidity: 30%-80%

[0085] Method: Stick the tester on the surface of the film to be tested and read the data.

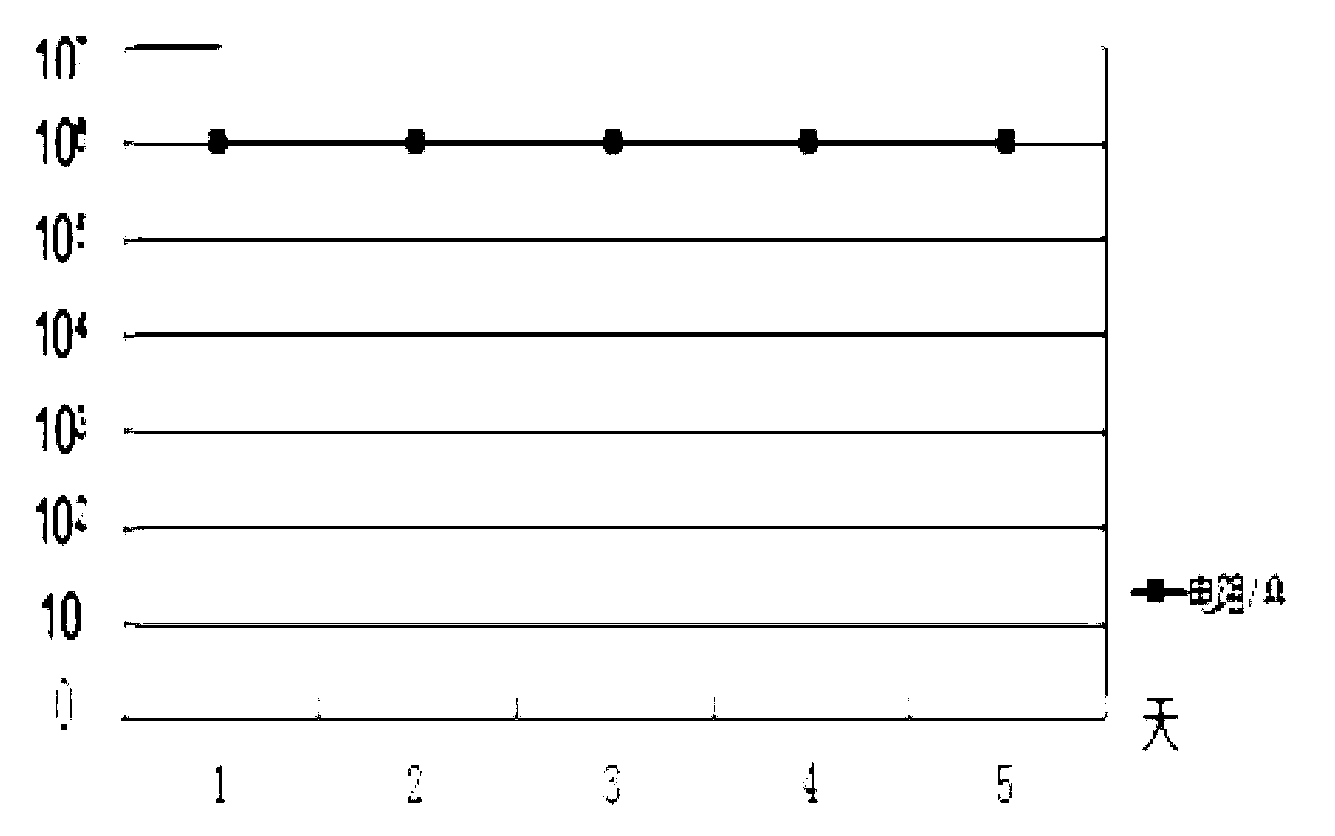

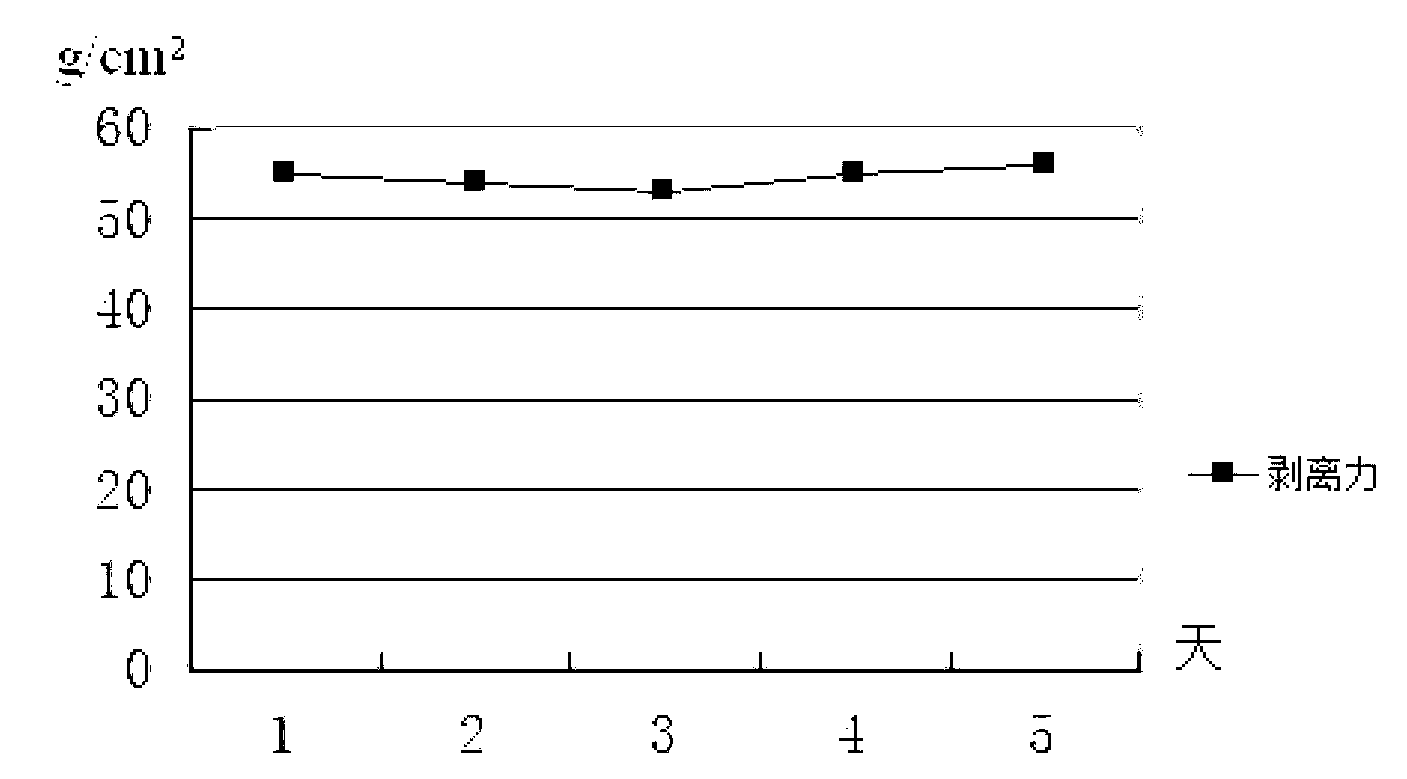

[0086] To test the antistatic ability of the antistatic release film of Example 1, the above test method was used to measure a set of data every 24 hours, and each set of data was measured 5 times, and the average value was taken. The control group used commercially available anti-static release film (purchased from Xinhao Adhesive Products Factory)

[0087] figure 2 The test data shows that the antistatic force is very stable and will not fluctuate significantly with time. It is better than the anti-static release film currently on the market. The resistance value of the anti-static release film on the market will increase with time, and the anti-static ability will d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com