Xanthan gum fracturing fluid, and preparation method and application thereof

A technology of xanthan gum and fracturing fluid, applied in the field of fracturing fluid, can solve the problems of limiting the application of water-based guar gum fracturing fluid, high cost of water-based guar gum fracturing fluid, low sand-carrying ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

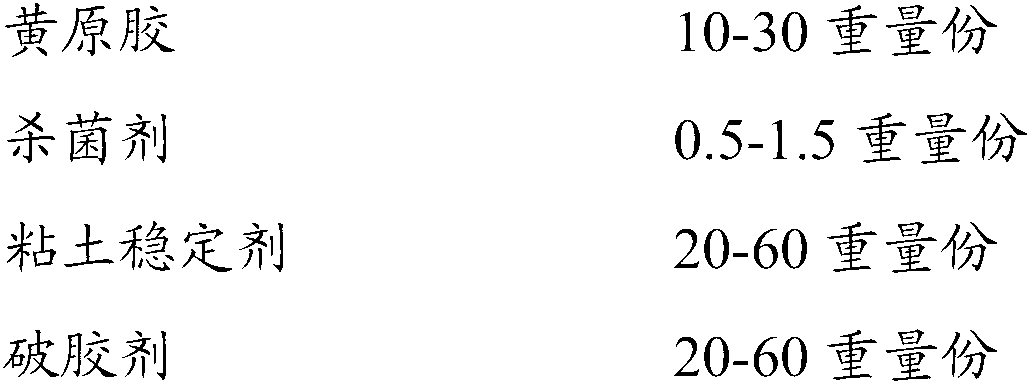

[0026] formula:

[0027]

[0028]

[0029] Among them, the bactericide is paraformaldehyde; the clay stabilizer is potassium chloride; the gel breaker is ammonium persulfate; the pH regulator is sodium carbonate; the crosslinking agent is chromium trichloride; Iron.

[0030] Preparation:

[0031] (1) Add xanthan gum, bactericide, clay stabilizer and gel breaker of formula quantity in 20 kilowatts dry powder mixing equipment, obtain uniform powder after mixing for 8 hours;

[0032] (2) The pH regulator solution is prepared as a pH regulator solution with a mass fraction of 5%, stirred at 900 rpm for 4 hours, and the pH regulator solution is added to step (1) with 13 milliliters / second speed flow In the obtained powder, the first solution is obtained;

[0033] (3) preparing the crosslinking agent into a crosslinking agent solution with a mass fraction of 20%, and adding the crosslinking agent solution into the first solution under stirring to obtain a second solution; ...

Embodiment 2

[0038] formula:

[0039]

[0040]

[0041] Among them, the bactericide is paraformaldehyde; the clay stabilizer is potassium chloride; the gel breaker is potassium persulfate; the pH regulator is sodium bicarbonate; the crosslinking agent is chromium trichloride; ferric chloride.

[0042] Preparation:

[0043] (1) Add xanthan gum, bactericide, clay stabilizer and gel breaker of formula quantity in 25 kilowatts dry powder mixing equipment, obtain uniform powder after mixing 2 hours;

[0044] (2) The pH regulator solution is prepared as a pH regulator solution with a mass fraction of 7%, stirred at 1000 rpm for 5 hours, and the pH regulator solution is added to step (1) with a flow rate of 15 milliliters per second. In the obtained powder, the first solution is obtained;

[0045] (3) The cross-linking agent is prepared as a cross-linking agent solution with a mass fraction of 15%, and the cross-linking agent solution is added to the first solution under stirring to obta...

Embodiment 3

[0050] formula:

[0051]

[0052] Among them, the bactericide is glutaraldehyde; the clay stabilizer is potassium chloride; the gel breaker is ammonium persulfate; the pH regulator is sodium hydroxide; the crosslinking agent is chromium trichloride; ferric chloride.

[0053] Preparation:

[0054] (1) Add xanthan gum, bactericide, clay stabilizer and gel breaker of formula quantity in 15 kilowatts dry powder mixing equipment, obtain uniform powder after mixing 2 hours;

[0055](2) The pH regulator is prepared as a pH regulator solution with a mass fraction of 4%, stirred at 800 rpm for 3 hours, and the pH regulator solution is added to step (1) with a 10 ml / second speed flow In the obtained powder, the first solution is obtained;

[0056] (3) The cross-linking agent is prepared as a cross-linking agent solution with a mass fraction of 15%, and the cross-linking agent solution is added to the first solution under stirring to obtain a second solution;

[0057] (4) The low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com