Method for purifying methane at low temperature

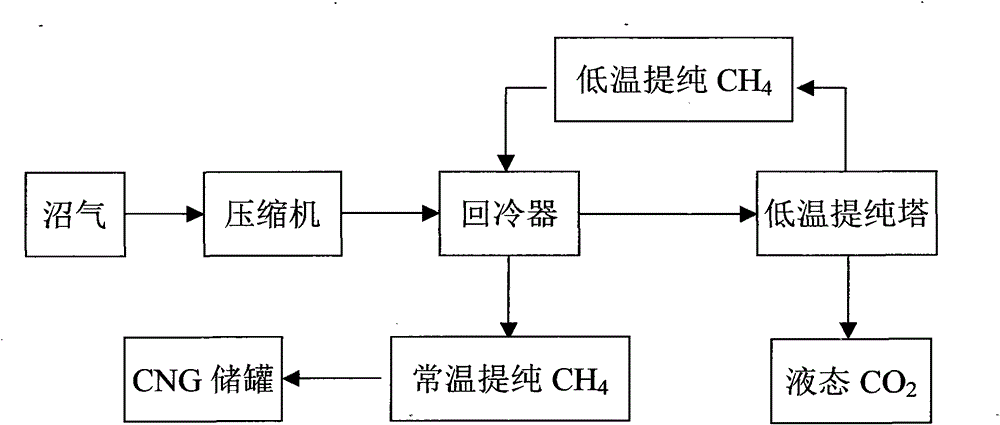

A purification method and biogas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of complex process equipment, dangerous LNG, high economic scale threshold, and achieve the effect of flexible operation scale, simple process and reduced operation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

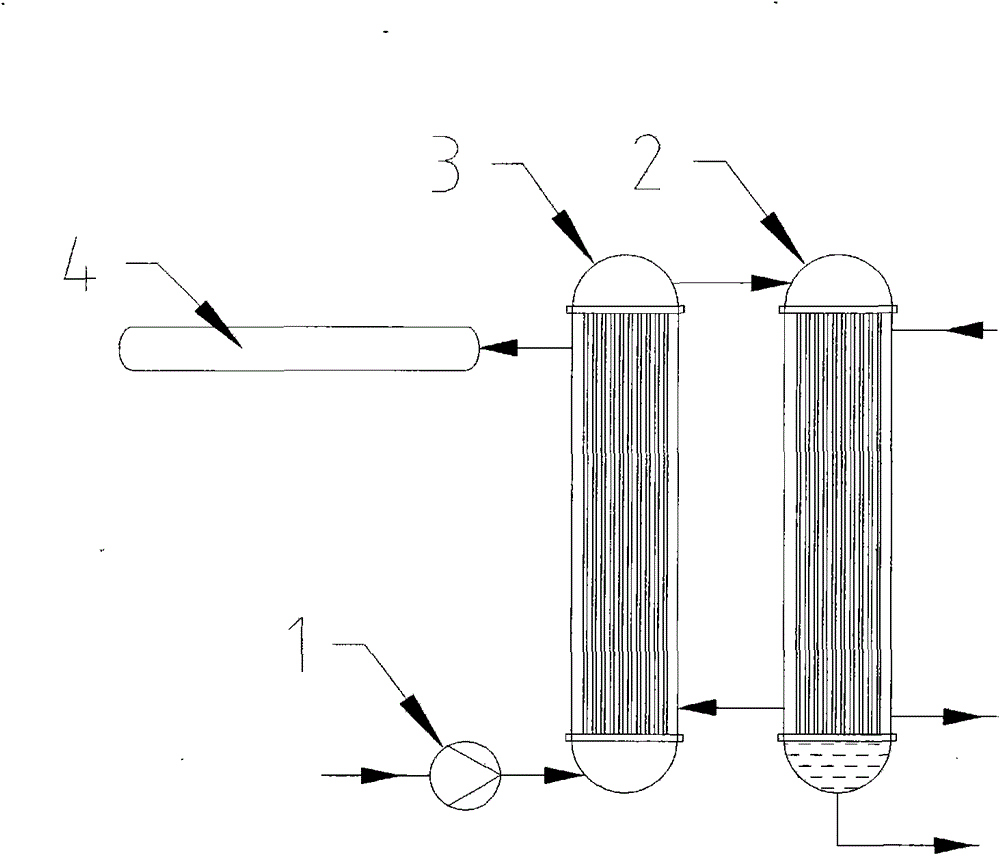

[0018] Such as figure 2 As shown, the biogas (CO 2 The content is about 40%, CH 4 The content is about 60%) pressurized to 25MPa by compressor 1, enters the low-temperature purification tower 2 through the recooler 3 (working pressure 25Mpa, working temperature -55°C, and can process an average of 70m of biogas per hour 3 / h,) at the top of the liquefied and precipitated liquid CO 2 discharged from the bottom, the purified CH 4 from liquid CO 2 It is discharged above the liquid level, and then enters the recooler 3, and after heat exchange with the treated biogas, the temperature rises to 10-15°C, and is discharged to the CNG storage bottle 4 at constant pressure. The main energy consumption of this device is the 7KW energy consumption of the refrigerator, and it is only necessary to monitor the refrigeration temperature and liquid CO during operation. 2 Liquid level, timed discharge of liquid CO 2 . An industrialized continuous purification method is provided for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com