Design of fanout trace in TFT-LCD (thin film transistor-liquid crystal display) narrow frame design

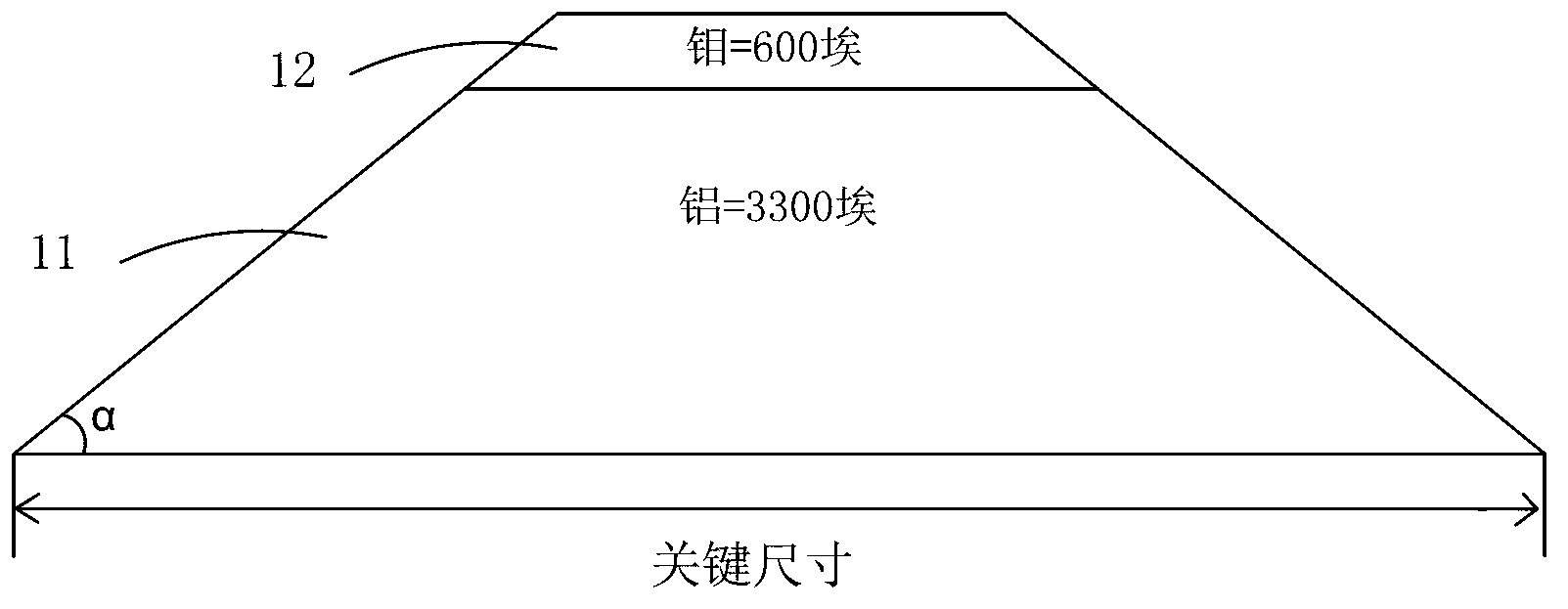

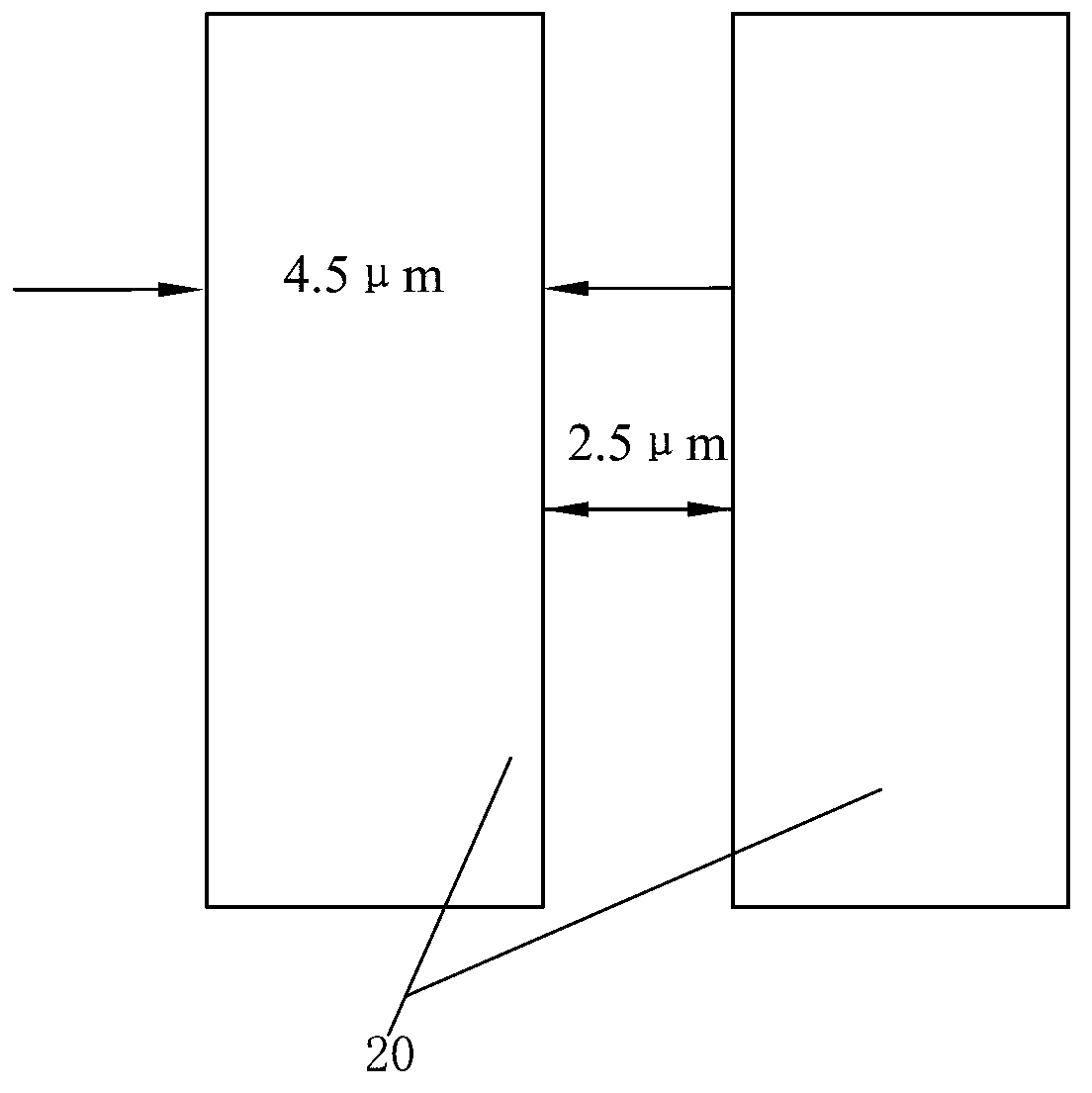

A narrow frame and line width technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of line width + spacing that cannot be realized in fan-out, achieve narrow frame design, increase metal key dimensions, and reduce fan-out height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

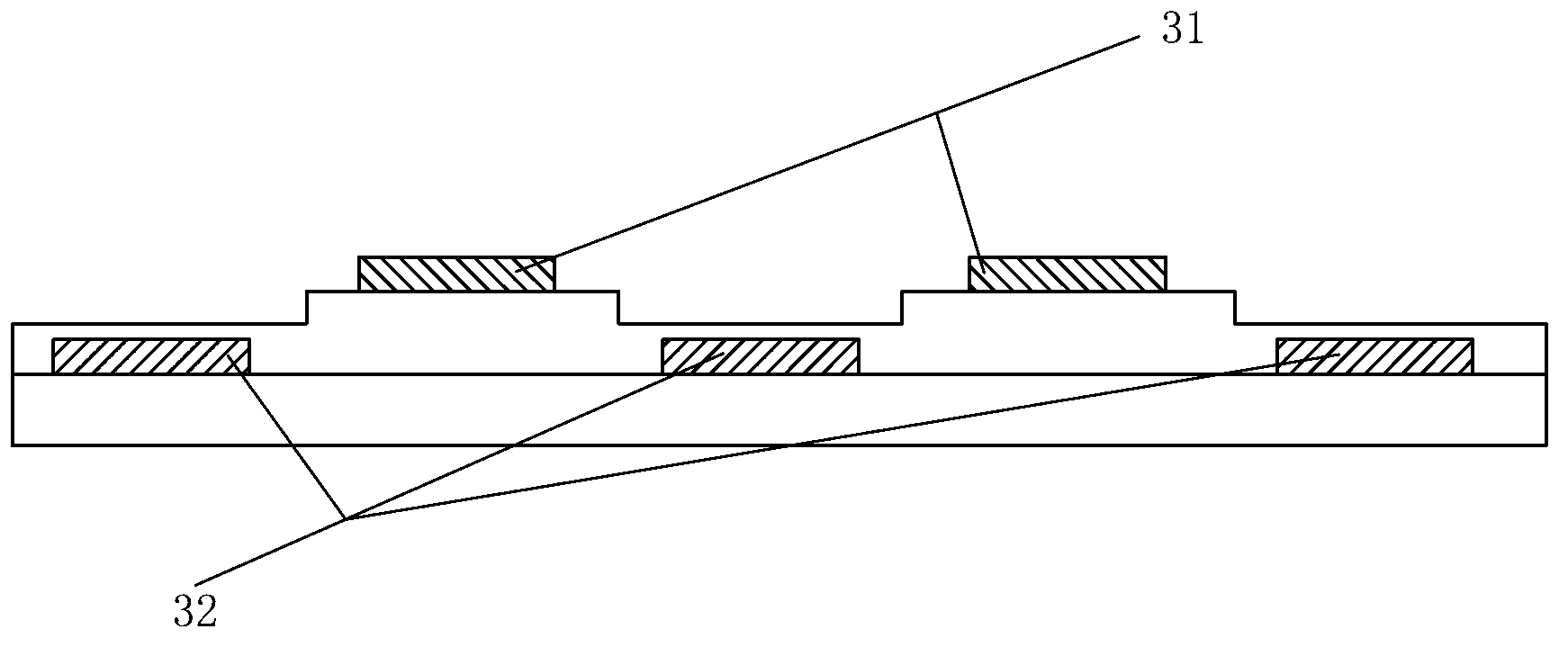

[0029] see image 3 As shown, it is a structural schematic diagram of a preferred embodiment of the fan-out wiring design in the TFT-LCD narrow frame design of the present invention. The design of the fan-out lines mainly includes: a first metal layer for etching the first fan-out lines 31 arranged in parallel and a second metal layer for etching the second fan-out lines 32 arranged in parallel, the first The metal layer and the second metal layer are arranged parallel up and down and are generally opposite to each other. The line width and fan-out pitch of the first fan-out line 31 are equal to the line width and fan-out pitch of the second fan-out line 32, so The projection of the first fan-out line 31 on the second metal layer is parallel to the second fan-out line 32 and intersects with the second fan-out line 32 at an equal distance. Since the focus of the present invention is on the design of the fan-out routing, related structures such as substrates, insulating layers,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com