Manufacturing method for novel aluminium alloy cable

A manufacturing method and technology of aluminum alloy, applied in cable/conductor manufacturing, insulation of conductor/cable, circuits, etc., can solve the problems of imperfect manufacturing method, difficulty in meeting smoke-free, halogen-free performance requirements, irregularity, etc. Operation standard, ensure the effect of industrialized production and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Non-limiting examples are as follows:

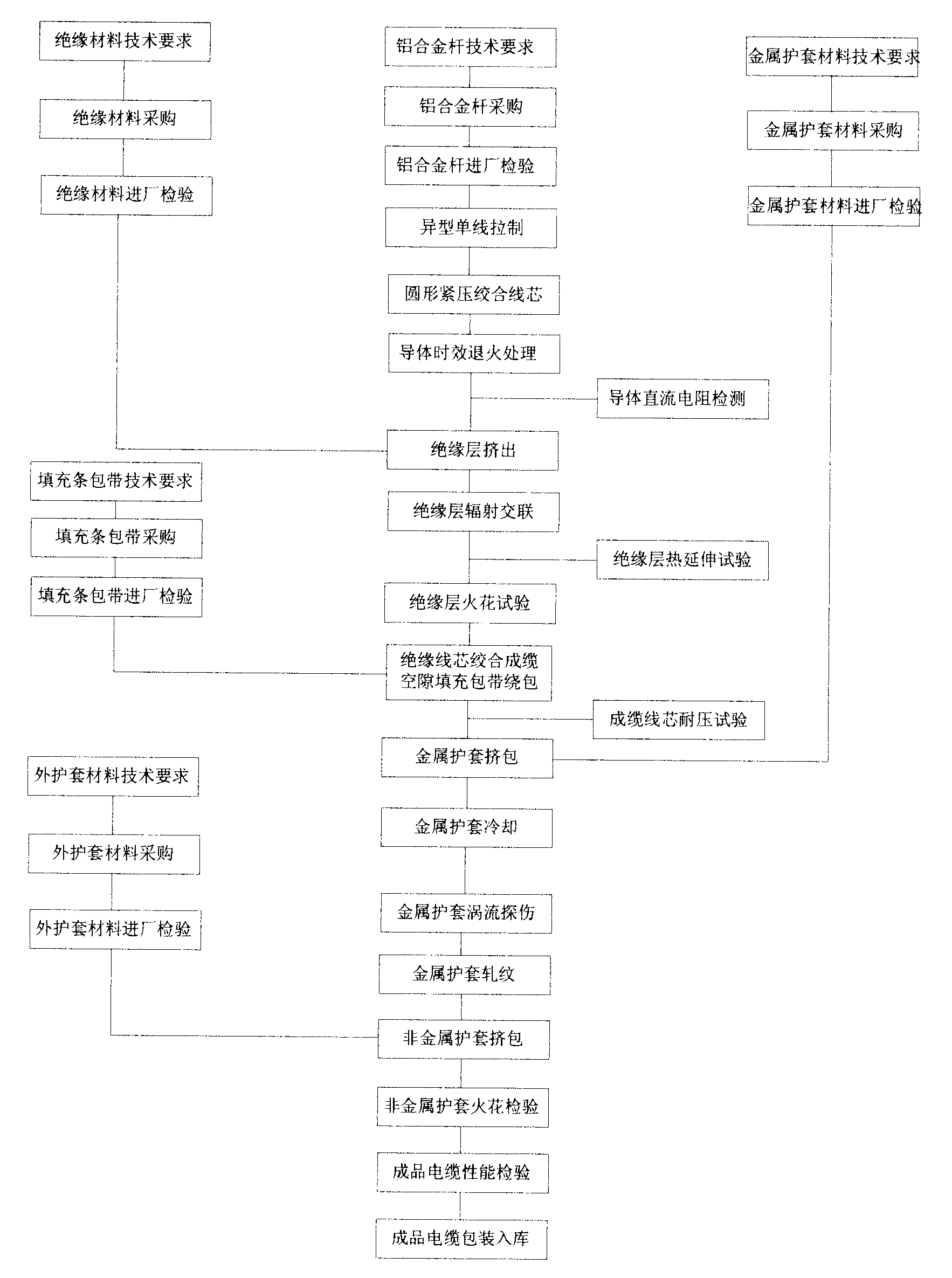

[0029] Referring to the accompanying drawings, this embodiment is a manufacturing method of a new type of aluminum alloy cable. The manufacturing steps are as follows: material selection requirements—purchasing of the above materials—incoming inspection of the above materials—drawing the conductor with a single wire—core Stranding—core aging annealing treatment—conductor DC resistance detection—insulation layer extrusion—insulation layer crosslinking—insulation thermal extension test—insulation spark inspection—insulation core stranding, gap filling and Wrapping isolation layer - cable core pressure test - metal sheath extrusion - metal sheath rapid cooling - metal sheath eddy current flaw detection - metal sheath corrugation - non-metal outer sheath extrusion ——Spark inspection of non-metallic outer sheath——Performance test of finished cables——Packing and warehousing of finished cables to manufacture cables. Annealing treatment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com