Method for arranging metal palladium layer in conducting layer of printed circuit board and layered structure thereof

A technology for printed circuit boards and conductive layers, applied in printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of brittle electroplating, high cost, shortened service life, etc., to reduce thickness and reduce material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

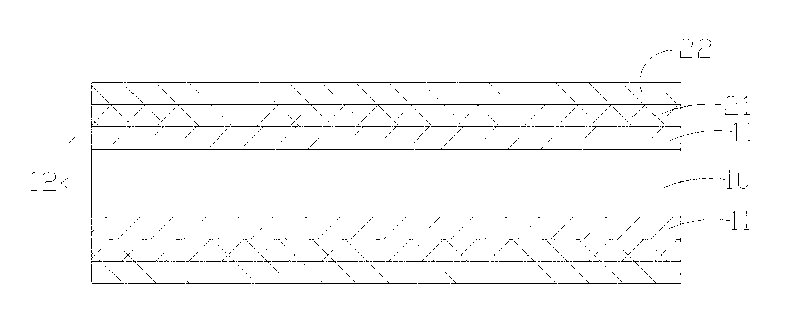

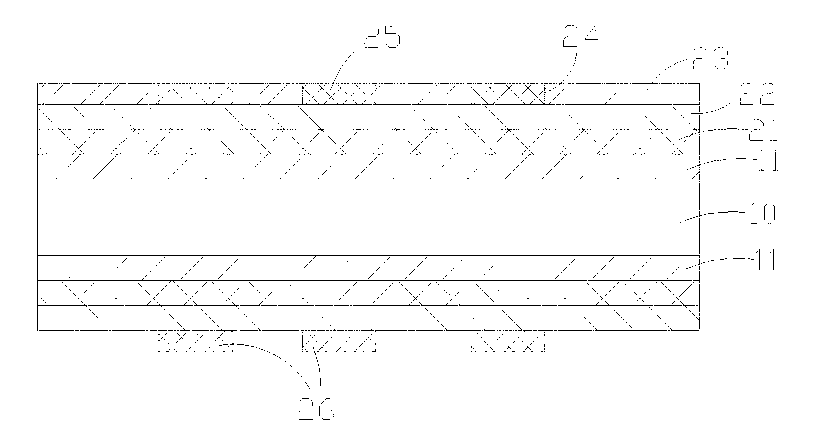

[0042] Such as Figures 1 to 6 Shown, a kind of method that metal palladium layer is set in the conductive layer of printed circuit board, it is characterized in that, comprises the steps:

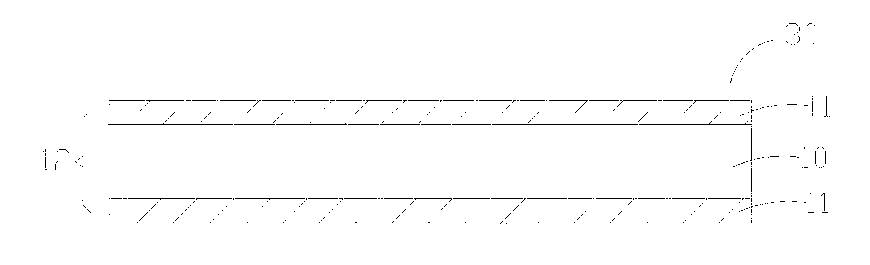

[0043] In the first step, copper cladding is performed on the insulating substrate 10 , and copper foil 11 is coated on one side or both sides of the insulating substrate 10 to form a copper clad laminate 12 .

[0044] Specifically, it may be determined according to production requirements whether to coat copper on one side or both sides of the insulating substrate 10 .

[0045] In the present invention, if adopt the mode of electroplating to carry out copper cladding, due to double-sided simultaneous electroplating during electroplating, when requiring layer to thicken copper plating, also can be thickened copper plating on another layer, if copper plating is too thick, will It affects the subsequent circuit fabrication, so it is necessary to thin the copper plating layer, so the acidic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com