Culture substrate, culture sheet, and cell culture method

A technology of cell culture and equipment, applied in cell culture support/coating, 3D culture, tissue culture, etc., can solve the problems of loss, uneven size, high three-dimensional tissue stripping, etc., and achieve efficient culture methods and uniform size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1 shows an example in which a culture sheet is applied to a chamber culture slide as a culture sheet holding member. Hereinafter, a sheet having a partition wall structure forming a culture region of the present invention and a plurality of protrusions formed inside the partition wall structure is referred to as a culture sheet compared to a conventional nanopillar sheet. The culture sheet is made of a material that does not adversely affect the cells, in this example polystyrene. However, the material is of course not limited to polystyrene.

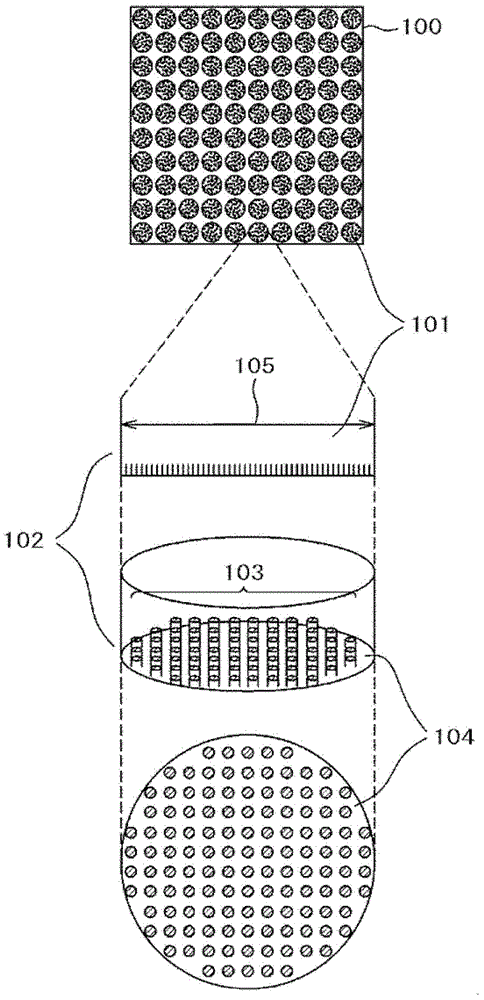

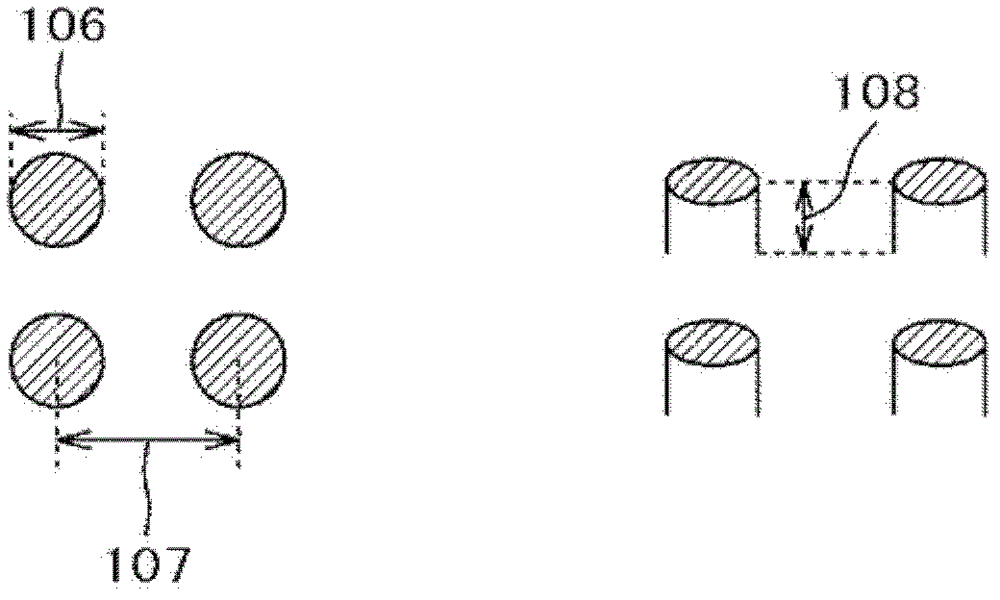

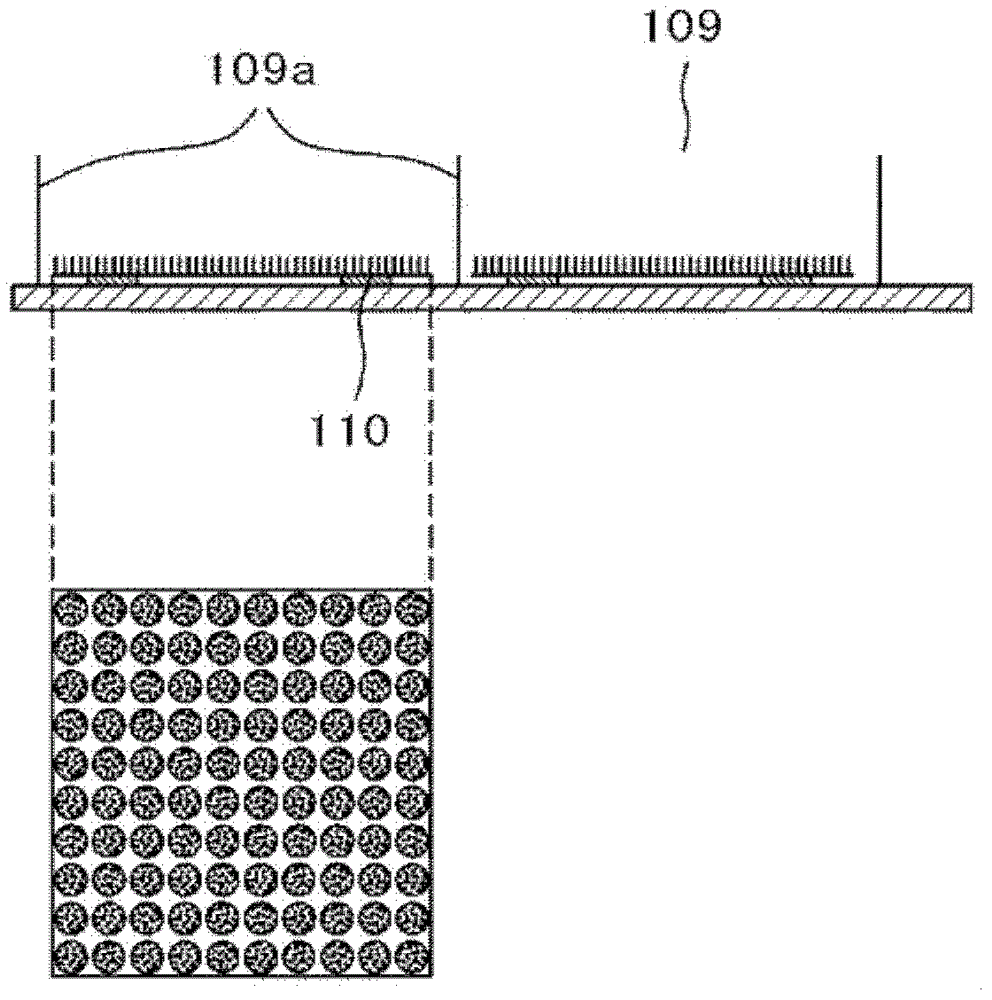

[0060] figure 1 It is a schematic diagram of a scanning electron micrograph of the culture sheet 100 prepared in this example. Also, the structure of one of the wells 101 (hereinafter referred to as wells) constituted by a plurality of partition wall structures 102 existing in each culture sheet is also shown. The inside of the well 101 constitutes a culture area of the cell tissue forming unit.

[0061] The plurali...

Embodiment 2

[0080] Next, according to Figure 4 , Figure 5 The second embodiment will be described. In Example 2, the configuration of a multiwell plate with a culture sheet and its production example are shown. Figure 4 (a) is a bottom view of the frame 111 constituting the perforated plate. The frame body 111 as a culture sheet holding member is formed into a cylindrical hole with a total of 24 holes with 4 holes in a row and 6 holes in a row with a width of about 125 mm, a length of about 80 mm, and a height of about 20 mm. Section 111a. The raw material uses polystyrene.

[0081] The number of holes formed in the frame is usually from 6 holes to 1536 holes depending on the application, so the frame is not limited to 24 holes. In addition, the material of the frame is not limited to polystyrene.

[0082] In the production of the culture equipment, the frame body 111 and the culture sheet 100 are joined by ultrasonic welding.

[0083] The following processing is performed on th...

Embodiment 3

[0109] Example 3 shows an example of application to cell tissue culture using the culture equipment produced in Examples 1 and 2. In the development of new drugs, the construction of three-dimensional tissues reflecting the functions of living bodies is required for various evaluations using cells instead of animal experiments.

[0110] In addition, since induced pluripotent stem cells (Induced pluripotent stem cells: iPS cells) or embryonic stem cells (Embryonic stem cells: ES cells) must be formed into three-dimensional tissues before they are cultured and differentiated into target cells, it is expected to be easily constructed in the field of regenerative medicine Techniques for three-dimensional organization. From this background, here is an example of forming a three-dimensional tissue using a chamber culture slide, but the essential part of cell culture is not particularly changed even in a multi-well plate. In this example, an example using rat hepatocytes was shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com