Aluminum magnesium continuous casting tundish slag-retaining wall and preparation method thereof

A continuous casting, aluminum-magnesium technology, applied in the field of refractory materials, can solve the problems of not having high cost performance and high manufacturing cost, and achieve good anti-scouring performance of molten steel, long service life and small line change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

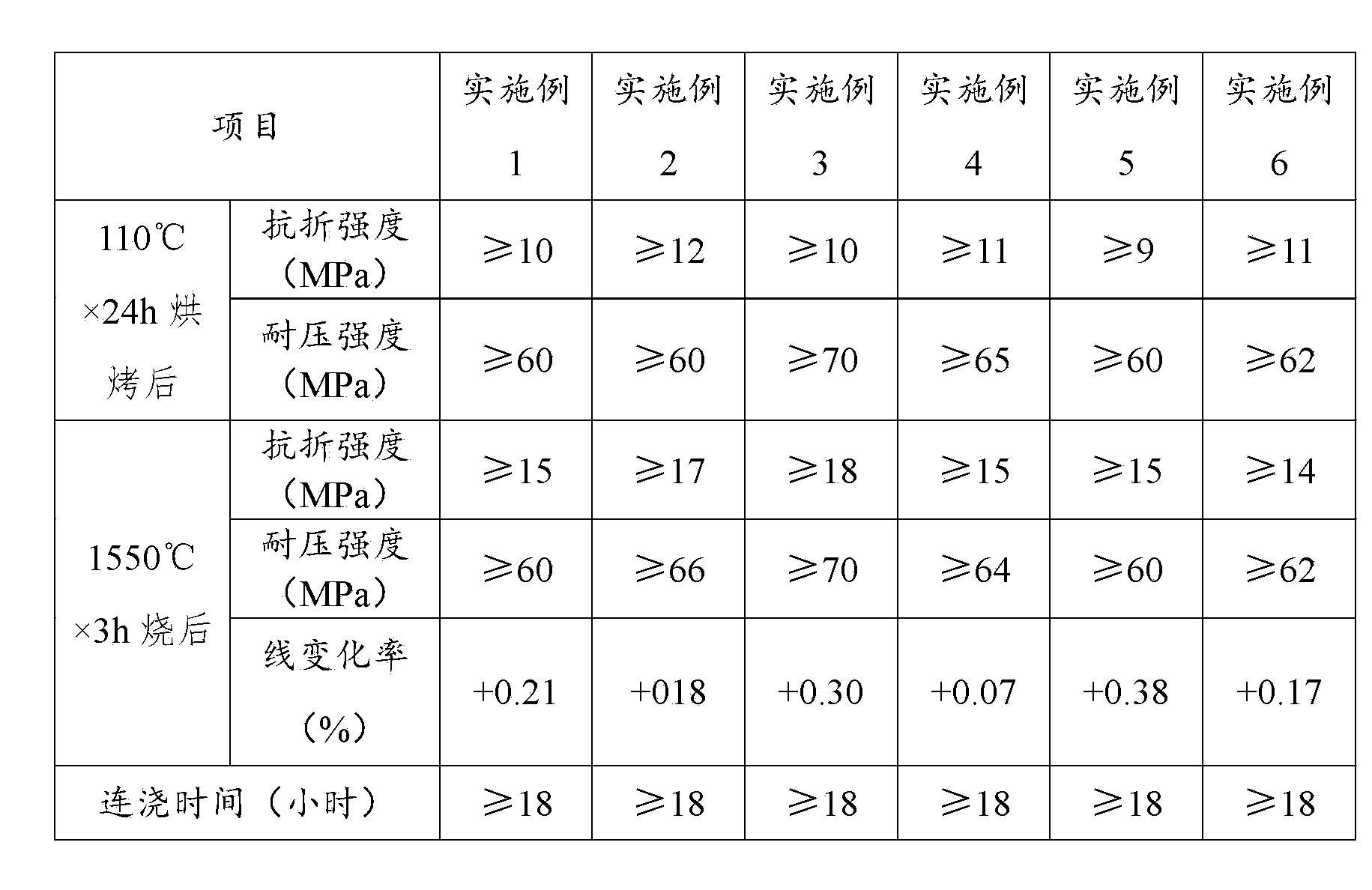

Examples

Embodiment 1

[0029] In this example, the parts by weight of the components of the slag retaining wall of the aluminum-magnesium continuous casting tundish are as follows: high alumina aggregate: 50, magnesium aggregate: 20, fine powder: 20, fine powder: 5, binder : 5, explosion-proof agent: 0.1, water reducing agent: 0.1. Among them, high alumina aggregates include: 8mm2 o 3 The first-grade bauxite with a content of ≥79% accounts for 28%, 17%, 20%, 20% and 15% by weight of the high-alumina aggregate. Magnesia aggregates include: 3mm2 micronized, the SiO 2 Micropowder, SiO 2 Content ≥ 92%, particle size ≤ 45μm. The binder is calcium aluminate cement, and in the calcium aluminate cement, Al 2 o 3 Content ≥ 69%, CaO content ≤ 30%. The explosion-proof agent is polypropylene fiber. The water reducer is a mixture of sodium tripolyphosphate and sodium hexametaphosphate.

Embodiment 2

[0031] In this example, the parts by weight of the components of the slag retaining wall of the aluminum-magnesium continuous casting tundish are as follows: high-alumina aggregate: 70, magnesium aggregate: 5, fine powder: 20, fine powder: 2, binder : 3, explosion-proof agent: 1, water reducing agent: 0.5. Among them, high alumina aggregates include: 8mm2 o 3The super-grade bauxite with a content ≥ 85% accounts for 30%, 15%, 18%, 22% and 15% by weight of the high-alumina aggregate. Magnesia aggregates include: sintered magnesia with MgO content ≥85% in three grades of 5mm2 Micropowder and α-Al 2 o 3 A mixture of micropowders, the SiO 2 Micropowder, SiO 2 Content ≥ 92%, particle size ≤ 45μm, the α-Al 2 o 3 In micropowder, α-Al 2 o 3 Content ≥ 99%, particle size ≤ 2μm. The binder is calcium aluminate cement, and in the calcium aluminate cement, Al 2 o 3 Content ≥ 69%, CaO content ≤ 30%. The explosion-proof agent is glass fiber. The water reducer is sodium tripolypho...

Embodiment 3

[0033] In this example, the parts by weight of the components of the slag retaining wall of the aluminum-magnesium continuous casting tundish are as follows: high alumina aggregate: 60, magnesium aggregate: 8, fine powder: 22, fine powder: 3, binder : 7. Anti-explosion agent: 3. Water reducing agent: 2. Among them, high alumina aggregates include: 8mm2 o 3 The super-grade bauxite with a content ≥ 85% accounts for 32%, 13%, 20%, 22% and 13% by weight of the high-alumina aggregate. Magnesia aggregates include: 8mm2 Micropowder and α-Al 2 o 3 A mixture of micropowders, the SiO 2 Micropowder, SiO 2 Content ≥ 92%, particle size ≤ 45μm, the α-Al 2 o 3 In micropowder, α-Al 2 o 3 Content ≥ 99%, particle size ≤ 2μm. The binder is calcium aluminate cement, and in the calcium aluminate cement, Al 2 o 3 Content ≥ 69%, CaO content ≤ 30%. The explosion-proof agent is stainless steel fiber. The water reducer is dispersed alumina (brand: ADS1 / ADW1, produced by Qingdao Anmai Alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com