High-value utilization method for oxygen-enriched coal tar

A coal tar, high-value technology, applied in the field of coal chemical industry, can solve the problems of increasing the hydrogen-oil volume ratio due to water pressure, economical uneconomical, and increased water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

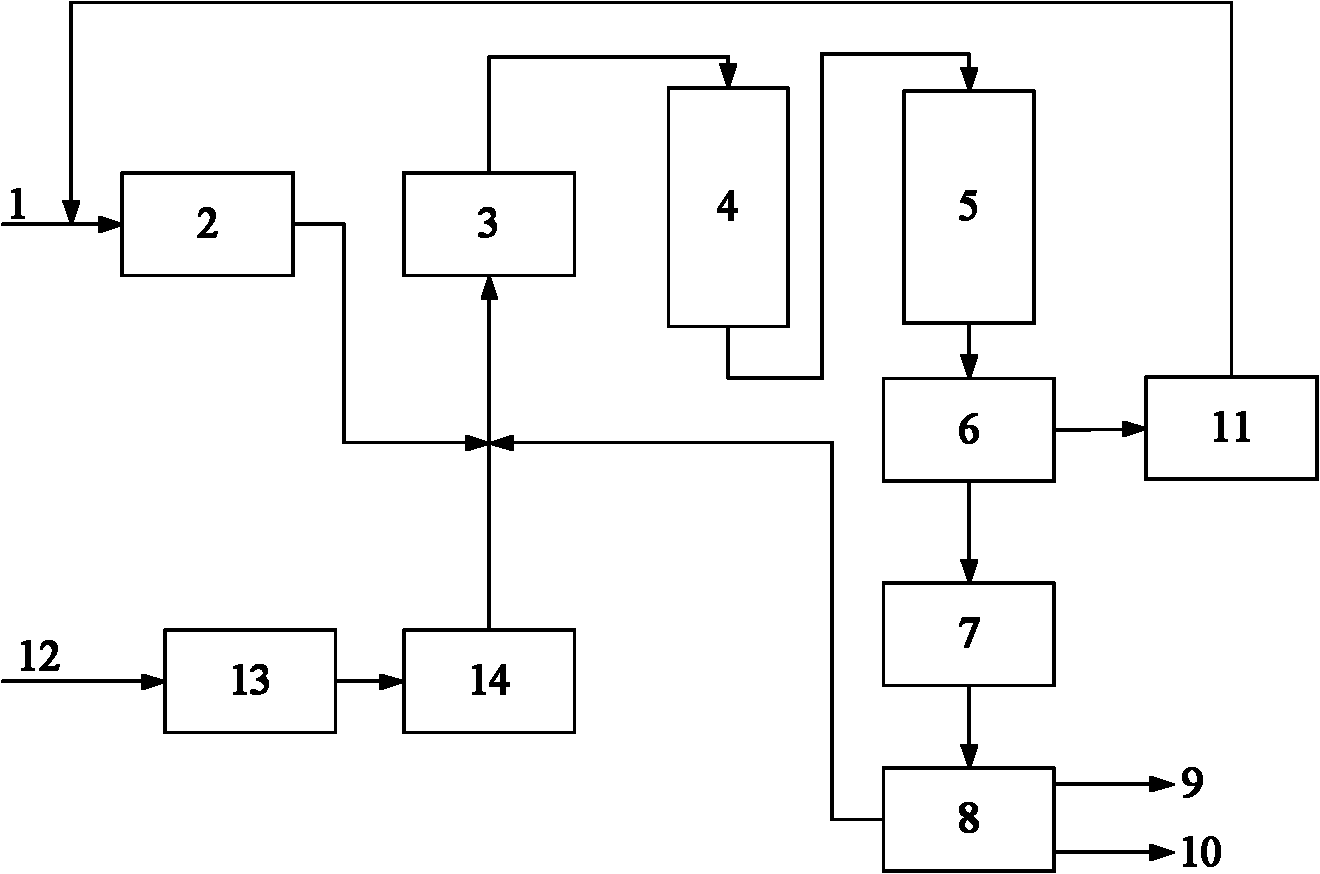

Method used

Image

Examples

Embodiment

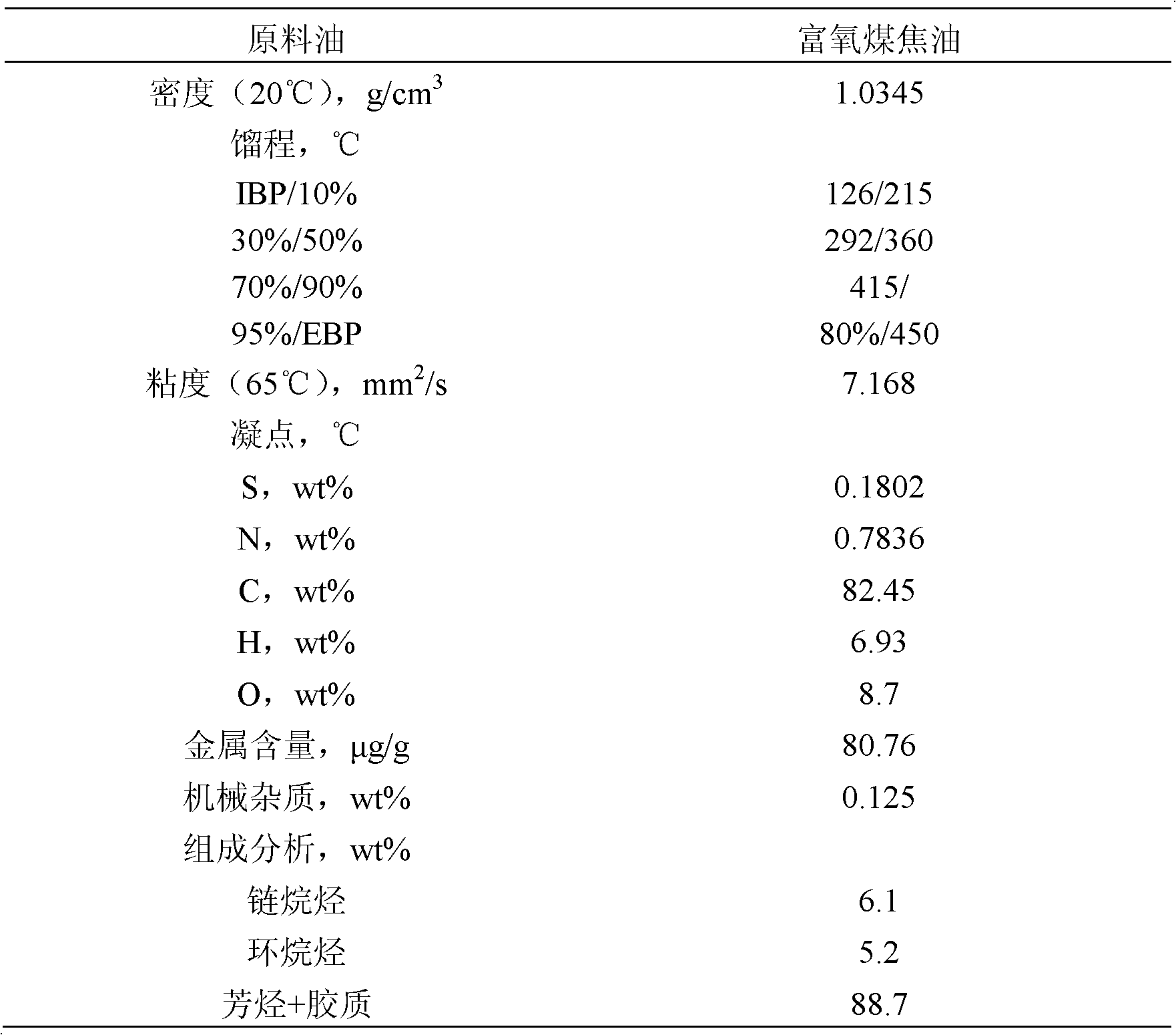

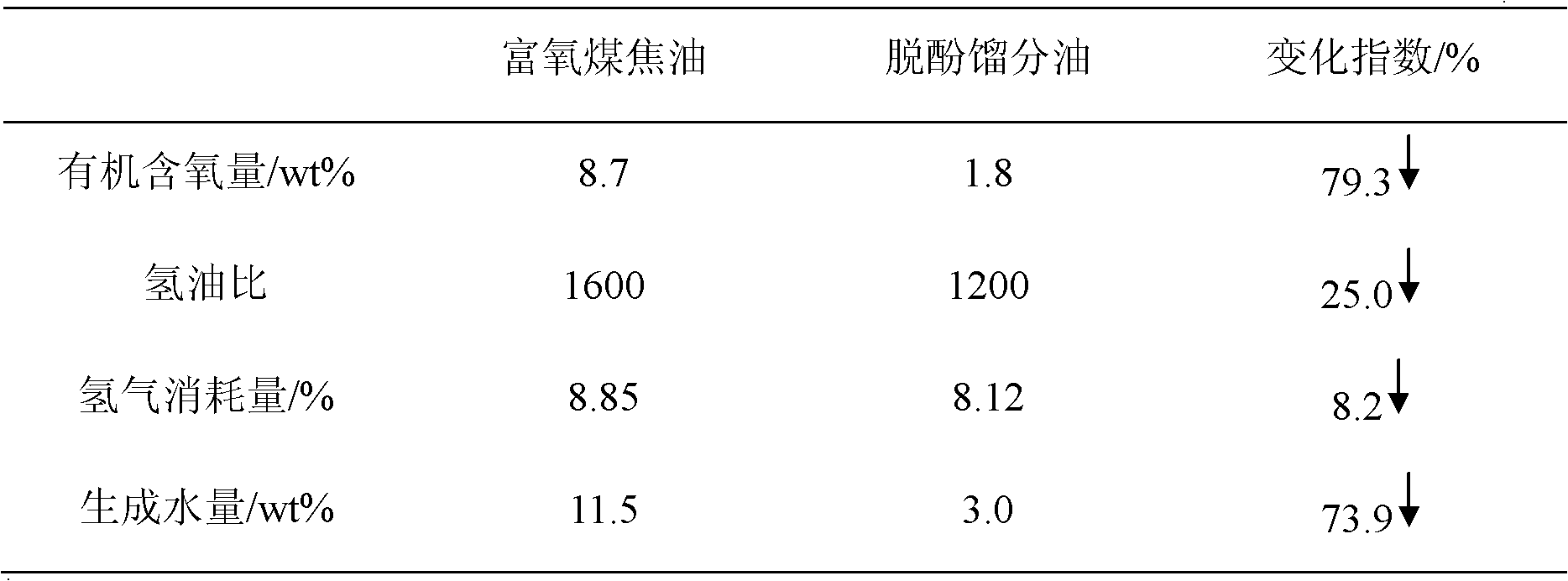

[0025] The raw material coal tar composition and main properties are listed in Table 1 in the specific examples of the present invention. The raw material oxygen-enriched coal tar has an organic oxygen content of 8.7%. It is divided into crude phenol oil and dephenolized fraction oil in the phenol extraction unit. The organic oxygen content in the dephenolized fraction oil is 1.8%. The crude phenol oil is used for phenol refining, and the dephenolized fraction The oil in the hydroconversion unit adopts a two-stage series hydrogenation process of hydrorefining and hydrocracking. The comparison between oxygen-enriched coal tar hydrogenation process and dephenolized distillate oil hydrogenation process is shown in Table 2. Table 2 mainly lists the changes in indicators such as hydrogen consumption, hydrogen-to-oil ratio, and generated water content. The high-value utilization method of oxygen-enriched coal tar of the present invention also has advantages in aspects such as equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com