Method for enriching platinum and palladium from pressurized cyanating solution

A technology for enriching and desorbing liquid, which is applied in the field of palladium and platinum extraction, can solve the problems that the zinc contained in the liquid is difficult to return and use, and the operation is complicated, and achieves the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment is to measure the [Pt(CN) of commercial coconut shell activated carbon at different concentrations. 4 ] 2- The saturated adsorption capacity of Pt in the solution is specifically:

[0024] Weigh 1.0 g of commercial coconut shell activated carbon with a particle size of 6 to 16 mesh, and add it to 800 mL [Pt(CN) 4 ] 2- In the alkaline cyanide solution, the concentration of platinum solution was 5.87 mg / L, and then weighed 2.0 grams of commercial coconut shell activated carbon with a particle size of 6-16 mesh in quadruplicate, and added them to 500 mL [Pt (EN) 4 ] 2- In the alkaline cyanide solution, the concentration of platinum solution was 20.61 mg / L, 41.53 mg / L, 62.84 mg / L and 75.17 mg / L respectively, and was shaken and adsorbed on a Conrad oscillator for 4 hours, filtered, and the filtrate was determined for the concentration of metal ions. content. Calculate the [Pt(CN) of commercial coconut shell activated carbon at different concentra...

Embodiment 2

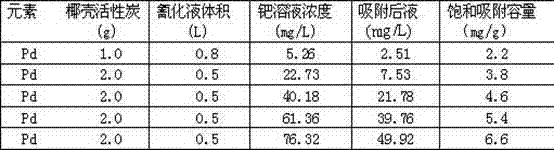

[0028] The present embodiment is to measure the [Pd(CN) of commercial coconut shell activated carbon at different concentrations. 4 ] 2- The saturated adsorption capacity of Pd in the solution is specifically:

[0029] Weigh 1.0 g of commercial coconut shell activated carbon with a particle size of 6 to 16 mesh, and add it to 800 mL [Pd(CN) 4 ] 2- In the alkaline cyanide solution, the concentration of the palladium solution was 5.26 mg / L, and then weighed 2.0 g of commercial coconut shell activated carbon with a particle size of 6-16 mesh in quadruplicate, and added them to 500 mL [Pd (EN) 4 ] 2- In the alkaline cyanide solution, the concentration of the palladium solution was 22.73 mg / L, 40.18 mg / L, 61.36 mg / L and 76.32 mg / L respectively, and it was shaken and adsorbed on a Kang's oscillator for 4 hours, filtered, and the filtrate was used to determine the concentration of Pd ions. content. Calculate the [Pd(CN) of coconut shell activated carbon at different concentra...

Embodiment 3

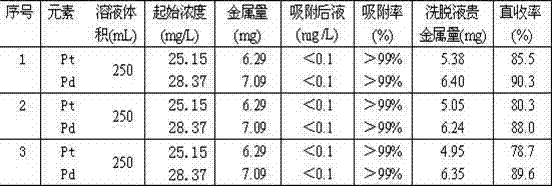

[0035] Weigh 25.17 grams of commercial coconut shell activated carbon with a particle size of 6 to 16 mesh, and add it to 500 mL [Pt(CN) 4 ] 2 and [Pd(CN) 4 ] 2- In the mixed alkaline cyanide solution, wherein the concentration of platinum solution is 20.47 mg / L, and the concentration of palladium solution is 23.48 mg / L, vibrate and adsorb on a Kang's oscillator for 4 hours, filter, and filter out [Pt(CN)4 ] 2- and [Pd(CN) 4 ] 2- For coconut shell activated carbon, use 40 mL of desorption solution, including 8 mL of ethanol and 32 mL of 2wt% NaOH solution, heat at 97°C, and desorb for 6 hours. The results are shown in Table 3.

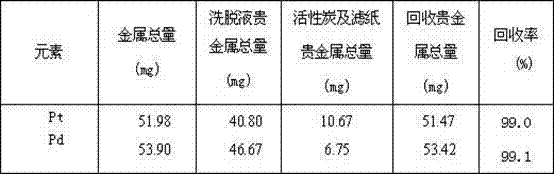

[0036] Table 3. Adsorption and Elution Experiment Ⅰ

[0037]

[0038] As can be seen from Table 3, from the cyanide solution of low concentration platinum and palladium, the adsorption rate of enriching platinum and palladium with activated carbon adsorption can be greater than 99%. 82.9% and 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com