Quick environment-friendly phosphorus-free phosphating solution

A phosphating solution and an environment-friendly technology, applied in the field of phosphating solution, can solve problems such as phosphorus emission restriction, and achieve the effect of convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

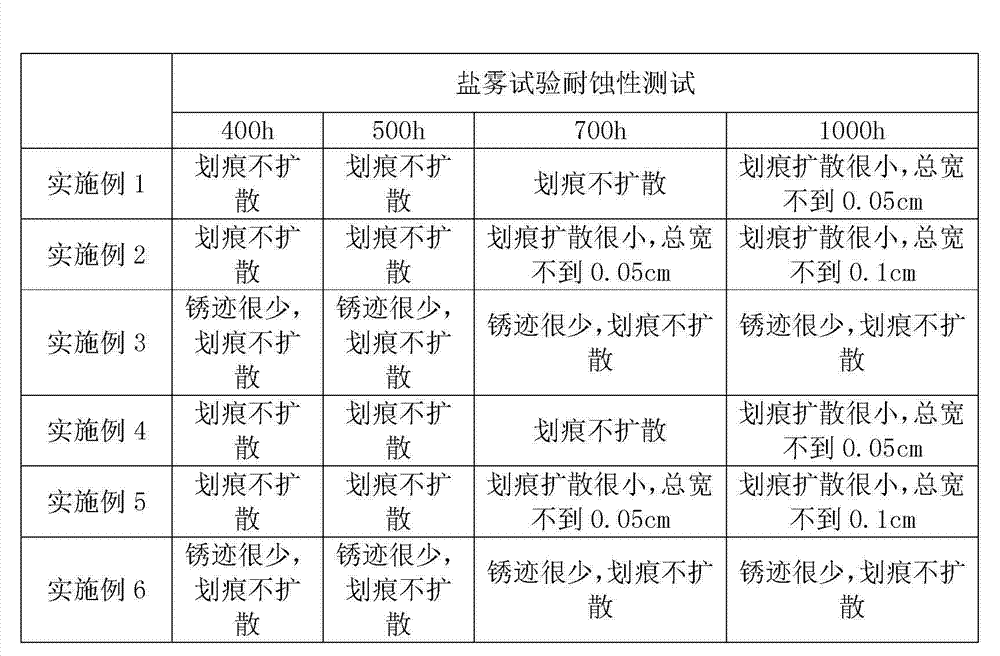

Examples

Embodiment 1

[0018] The phosphating solution of the present embodiment comprises the following components by weight: 4% ammonium fluorozirconate, 5% hydrofluoric acid, 1% boric acid, 0.1% ethylenediaminetetraacetic acid, 0.5% zinc molybdate, and the balance is water. Wherein: hydrofluoric acid is hydrofluoric acid aqueous solution, adopts 46% hydrofluoric acid to prepare the hydrofluoric acid aqueous solution that mass concentration is 24.5%. Control the conductivity range of the phosphating solution to be 6160 us / cm to 9000 us / cm, and the pH range to be 3.86 to 4.68.

[0019] The phosphating sample plate of this embodiment is a cold-rolled plate, and the process is spraying. In other embodiments, soaking can also be used, and the spraying effect is better.

[0020] Phosphating and post-treatment process includes the following steps:

[0021] (1) Degreasing the workpiece;

[0022] (2) Spray phosphating at room temperature around 20°C, and the phosphating time is 1 minute;

[0023] (3) ...

Embodiment 2

[0026] The phosphating solution of the present embodiment comprises the following components by weight: 5% ammonium fluozirconate, 6% hydrofluoric acid, 1.25% boric acid, 0.15% ethylenediaminetetraacetic acid, 1% zinc molybdate, and the balance is water. Wherein: hydrofluoric acid is hydrofluoric acid aqueous solution, adopts 46% hydrofluoric acid to prepare the hydrofluoric acid aqueous solution that mass concentration is 24.5%. Control the conductivity range of the phosphating solution to be 6160 us / cm to 9000 us / cm, and the pH range to be 3.86 to 4.68.

[0027] The phosphating sample plate of this embodiment is a cold-rolled plate, and the process is spraying. In other embodiments, soaking can also be used, and the spraying effect is better.

[0028] Phosphating and post-treatment process includes the following steps:

[0029] (1) Degreasing the workpiece;

[0030] (2) Spray phosphating at room temperature around 20°C, and the phosphating time is 1.5 minutes;

[0031] (...

Embodiment 3

[0034] The phosphating solution of the present embodiment comprises the following components by weight: 6% ammonium fluorozirconate, 7% hydrofluoric acid, 1.5% boric acid, 0.2% ethylenediaminetetraacetic acid, 1.5% zinc molybdate, and the balance is water. Wherein: hydrofluoric acid is hydrofluoric acid aqueous solution, adopts 46% hydrofluoric acid to prepare the hydrofluoric acid aqueous solution that mass concentration is 24.5%. Control the conductivity range of the phosphating solution to be 6160 us / cm to 9000 us / cm, and the pH range to be 3.86 to 4.68.

[0035] The phosphating sample plate of this embodiment is a cold-rolled plate, and the process is spraying. In other embodiments, soaking can also be used, and the spraying effect is better.

[0036] Phosphating and post-treatment process includes the following steps:

[0037] (1) Degreasing the workpiece;

[0038] (2) Spray phosphating at room temperature around 20°C, and the phosphating time is 1.5 minutes;

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com