Super-hydrophobic paper and production method thereof

A super-hydrophobic paper and super-hydrophobic technology, applied in the field of nanotechnology or bionics, can solve the problems of paper loss of air permeability, no self-cleaning property, complicated process, etc., achieve high commercial application value, stable super-hydrophobic properties, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

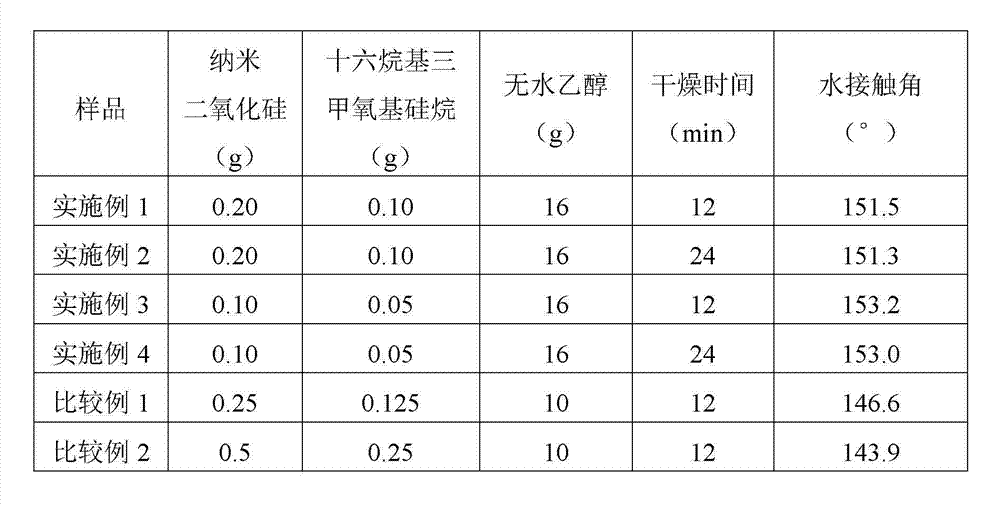

[0016] Weigh 0.20 g of nano silicon dioxide and add it to 16 g of absolute ethanol, ultrasonicate the resulting suspension for 10 min, then weigh 0.10 g of hexadecyltrimethoxysilane, add it to the above mixture, and ultrasonically for 10 min, A uniform and stable mixture was obtained. Then, the printing paper with text or pictures was soaked in the above mixture for 1 min, then taken out, and dried naturally at room temperature for 12 hours to obtain super-hydrophobic paper. The wettability of the paper surface was tested with a contact angle tester, and the result showed that the water contact angle of the surface was 151.5°. The surface morphology of the paper was observed with a scanning electron microscope, and it was found that a large number of protruding structures imitating lotus leaves were attached to the surface of the paper fibers. See Table 1.

Embodiment 2

[0018] Weigh 0.20 g of nano silicon dioxide and add it to 16 g of absolute ethanol, ultrasonicate the resulting suspension for 10 min, then weigh 0.10 g of hexadecyltrimethoxysilane, add it to the above mixture, and ultrasonically for 10 min, A uniform and stable mixture was obtained. Then, the printing paper with text or pictures was soaked in the above mixture for 1 min, then taken out, and dried naturally at room temperature for 24 hours to obtain super-hydrophobic paper. The wettability of the paper surface was tested with a contact angle tester, and the result showed that the water contact angle of the surface was 151.3°. The surface morphology of the paper was observed with a scanning electron microscope, and it was found that a large number of protruding structures imitating lotus leaves were attached to the surface of the paper fibers. See Table 1.

Embodiment 3

[0020] Weigh 0.10 g of nano silicon dioxide and add it into 16 g of absolute ethanol, ultrasonicate the resulting suspension for 10 min, then weigh 0.05 g of hexadecyltrimethoxysilane, add it to the above mixed solution, and ultrasonically for 10 min, A uniform and stable mixture was obtained. Then, the printing paper with text or pictures was soaked in the above mixture for 1 min, then taken out, and dried naturally at room temperature for 12 hours to obtain super-hydrophobic paper. The wettability of the paper surface was tested with a contact angle tester, and the result showed that the water contact angle of the surface was 153.2°. The surface morphology of the paper was observed with a scanning electron microscope, and it was found that a large number of protruding structures imitating lotus leaves were attached to the surface of the paper fibers. See Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com