Silver-plated copper containing paste for solar cell back electrode and method for preparing silver-plated copper containing paste

A technology for solar cells and back electrodes, which is applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. Good welding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

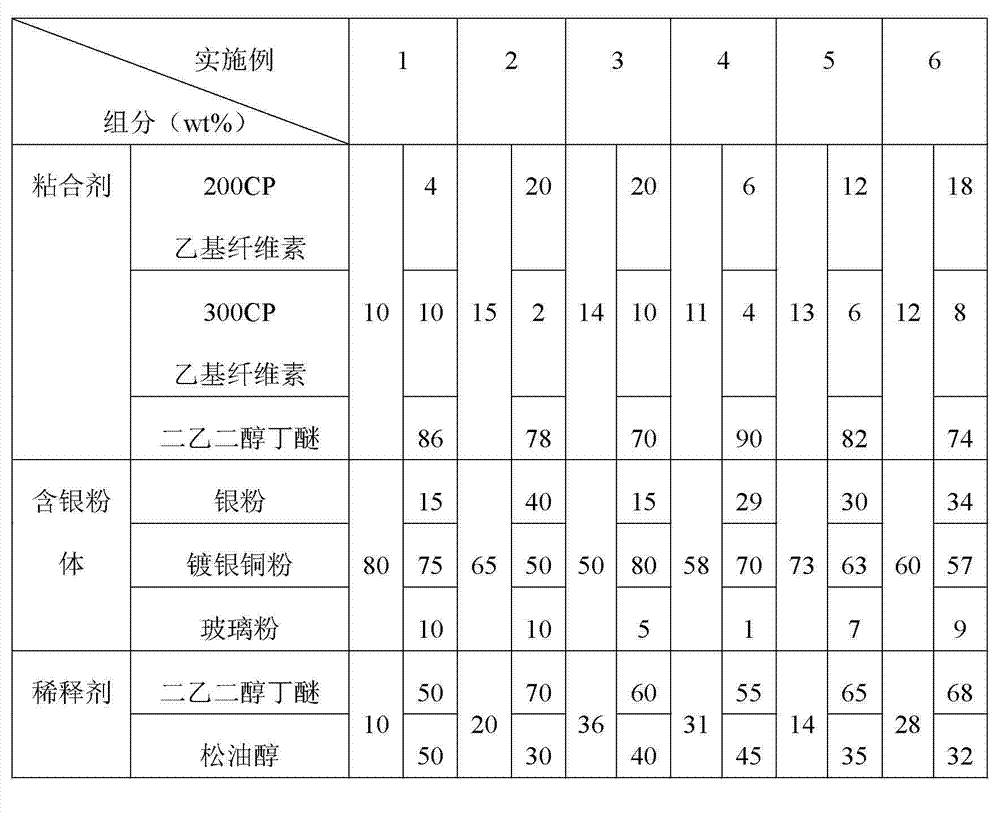

[0025] Embodiment: The formula of the solar cell back electrode containing silver-plated copper paste in Examples 1 to 6 of the present invention is shown in the following table 1:

[0026] Table 1 (unit: weight percentage)

[0027]

[0028] Wherein, the content of silver in the silver-plated copper powder is 2%-60% of the weight of the silver-plated copper powder. The particle size of the silver-plated copper powder is 0.1 micron-30 micron. The silver-plated copper powder is at least one of spherical silver-plated copper powder, flaky silver-plated copper powder and dendritic silver-plated copper powder.

[0029] According to the above formula, the preparation method of the solar cell back electrode containing silver-plated copper paste of the present invention is as follows:

[0030] 1. Preparation of adhesive: mixing ethyl cellulose with a dynamic viscosity of 200CP, ethyl cellulose and diethylene glycol butyl ether with a dynamic viscosity of 300CP in proportion to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com