Method for adjusting firing shrinkage of cordierite honeycomb ceramics by using amorphous silicon micropowder

A technology of cordierite honeycomb and shrinkage rate, which is applied in the field of manufacturing special ceramics, can solve problems such as large internal stress and product cracking, and achieve the effect of alleviating firing shrinkage and improving firing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The production test process route of the product is: batching→mixing→kneading→sliming→shaping→drying→processing→firing.

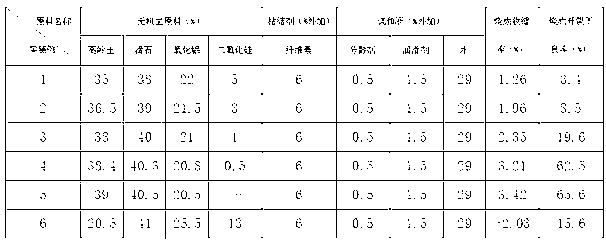

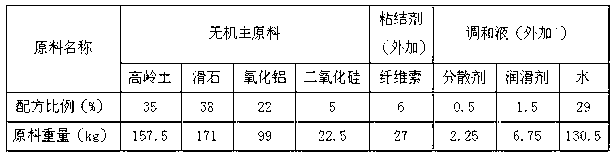

[0016] Use an electronic scale with an accuracy of 10g to weigh and weigh various raw materials according to the following ratios for batching operations:

[0017]

[0018] ※Extra: Refers to the inorganic main raw material as 100%, and a certain proportion of auxiliary raw materials added.

[0019] The specific process is as follows: add the weighed inorganic main raw materials and the added powder binder together into the powder mixer and mix for 45 minutes, so that all kinds of powder raw materials are fully mixed evenly. Pour the mixed powder raw materials into the kneader, and evenly spray the prepared blending liquid (dissolving the dispersant and lubricant in water) into the powder raw materials while turning on the kneader. After 120 After 10 minutes of kneading, the powder raw materials are kneaded into plastic lumps. The mud block is ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com