Method for extracting secoisolariciresinol diglucoside

A technology of flax lignans and extraction methods, which is applied in the field of extraction of flax lignans, can solve the problems of long extraction time, large solvent consumption, and low extraction volume, and achieve good appearance and color, high relative purity, and biological activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

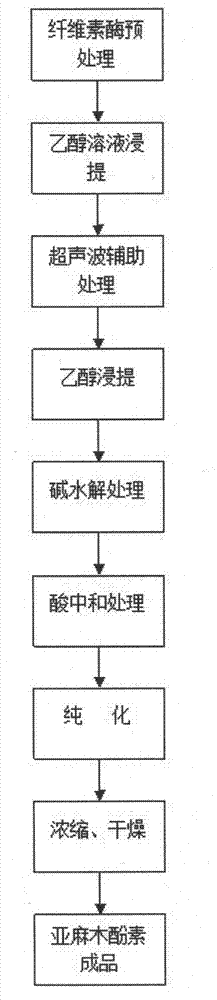

Image

Examples

Embodiment 1

[0030] (1) Weigh 100g of flax cake, add 5g of cellulase, add 500ml of distilled water, stir evenly, adjust pH=4.0, and pretreat for 20min in a water bath at 50°C;

[0031] (2) Adjust the pH to 7.0, add 1167ml of absolute ethanol to make the final concentration 70%, continue stirring and extracting for 30 minutes, ultrasonically assist treatment for 20 minutes, then continue stirring and extracting, after 3 hours in a 50°C water bath, centrifuge at 1500rmp for 10 minutes , take the supernatant.

[0032] (3) Add NaOH solution to the supernatant to adjust the pH=11.5, stir and hydrolyze for 1.5h, keep the pH=11.5 unchanged during this process, centrifuge at 3000rmp for 10min, neutralize the obtained supernatant with HCl solution, adjust the pH to 4.0, Obtain the flax lignans crude extract;

[0033] (4) The crude extract obtained in the previous step is adsorbed through AB-8 type macroporous resin chromatography, and the flow velocity is controlled at 0.5cm / min;

[0034] (5) elu...

Embodiment 2

[0036] (1) Weigh 100g of flax cake, add 5g of cellulase, add 500ml of distilled water, stir evenly, adjust pH=4.2, and pretreat for 30min in a water bath at 55°C;

[0037] (2) Adjust the pH to 7.0, add 1167ml of absolute ethanol to make the final concentration 70%, continue stirring and extracting for 30 minutes, ultrasonically assist treatment for 20 minutes, then continue stirring and extracting, after 3.5 hours in a 55°C water bath, centrifuge at 1500rmp for 5 minutes , take the supernatant.

[0038] (3) Add NaOH solution to the supernatant to adjust pH=12, stir and hydrolyze for 2h, keep pH=12 in the process, centrifuge at 3000rmp for 10min, neutralize the obtained supernatant with HCl solution, and adjust the pH to 4.2 to obtain Flax lignans crude extract;

[0039] (4) The crude extract obtained in the previous step is subjected to AB-8 macroporous resin chromatography adsorption, and the flow rate is controlled at 0.5cm / mim

[0040] (5) Elution with 20% ethanol solutio...

Embodiment 3

[0042] (1) Weigh 100g of flax cake, add 5g of cellulase, add 500ml of distilled water, stir evenly, adjust pH=4.5, and pretreat for 40min in a water bath at 60°C;

[0043](2) Adjust the pH to 7.0, add 1167ml of absolute ethanol to make the final concentration 70%, continue stirring and extracting for 30 minutes, ultrasonically assist treatment for 20 minutes, then continue stirring and extracting, after 4 hours in a water bath at 60°C, centrifuge at 1500rmp for 10 minutes , take the supernatant.

[0044] (3) Add NaOH solution to the supernatant to adjust the pH=12.5, stir and hydrolyze for 2.5h, keep the pH=12.5 constant during this process, centrifuge at 3000rmp for 15min, neutralize the obtained supernatant with HCl solution, adjust the pH to 4.5, Obtain the flax lignans crude extract;

[0045] (4) The crude extract obtained in the previous step is adsorbed through AB-8 type macroporous resin chromatography, and the flow velocity is controlled at 0.5cm / min;

[0046] (5) El...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com