Device for generating electricity from waste heat of raw coke oven gas

A waste heat power generation and power generation device technology, which is applied in the heating of coke ovens, carbonization gas discharge devices, coke ovens, etc., can solve the problems of inability to fully recover and utilize waste heat resources of raw coal gas, narrow space structure, and influence of hot surface layout, etc. , to achieve the effects of reducing energy consumption, improving steam quality, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

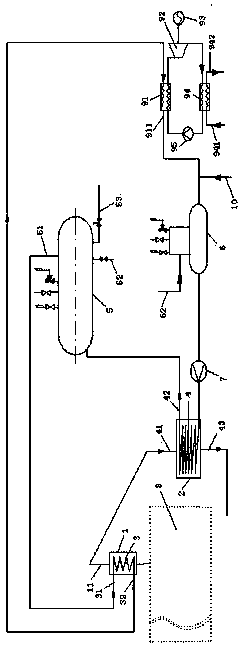

[0025] see figure 1 , the coke oven waste gas waste heat power generation device of the present invention includes a heat extraction subsystem and a power generation subsystem, and the heat extraction subsystem includes a superheater 3, a bridge tube evaporator 4, a steam drum 5 and a deoxygenation and desalination water supply device, and the superheater 3 is installed in the riser pipe 1 of the coke oven 8, the bridge pipe evaporator 4 is arranged in the bridge pipe 2, the outlet 11 of the riser pipe 1 is connected with the raw gas inlet 41 of the bridge pipe 2 through a pipe, and the deoxygenation and desalination water supply device The outlet is connected to the deoxygenated and desalted water inlet of the evaporator 4, the steam-water outlet 42 of the bridge tube evaporator is connected to the steam-water mixture inlet of the steam drum 5, the saturated steam o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com