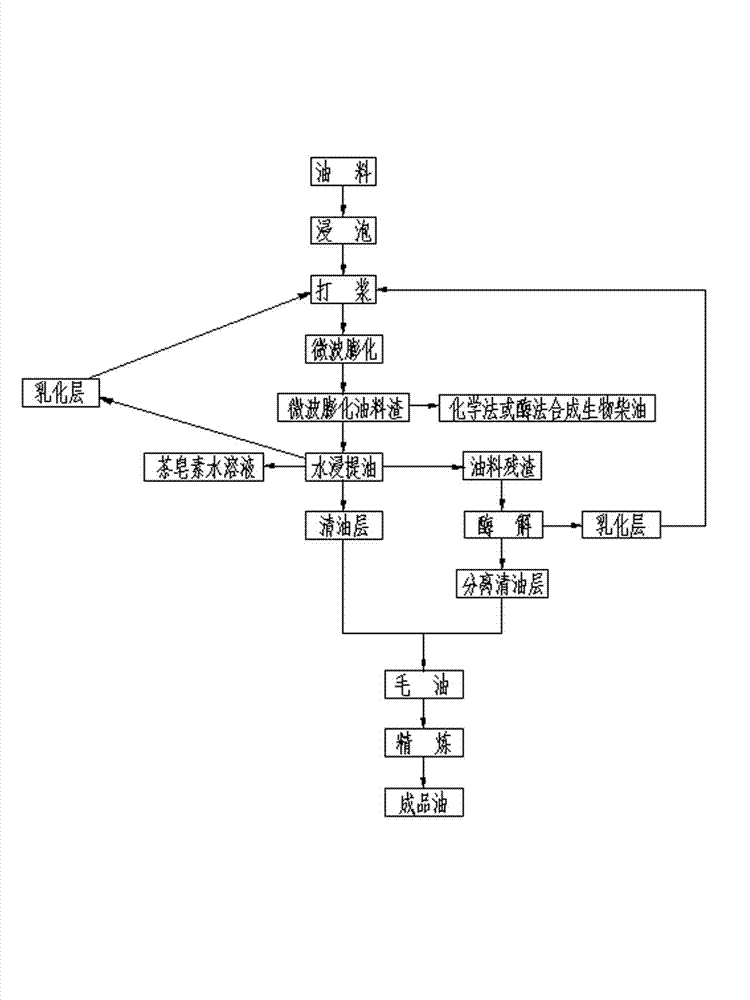

Method for digesting grease through microwave pretreatment and aqueous enzymatic method

A kind of pretreatment, water enzymatic technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of low oil yield of tea seed oil, restricted application, etc., achieve simple and environmentally friendly process, improve oil yield, output The effect of high oil rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Weigh 10 grams of microwave puffed pretreated safflower camellia seed kernel dregs, add 50 ml of water, stir at room temperature for 1 hour, and separate the oil layer After mixing with the water layer, add water to the residue, adjust the pH to 6-7 with hydrochloric acid solution, add 2% neutral protease, enzymatically hydrolyze at 55°C for 3 hours, and separate the oil layer , to merge oil layers and oil layer , 5.4 grams of Mao-camellia oil can be obtained.

Embodiment 2

[0026] Example 2: Weigh 10 grams of microwave puffed pretreated safflower camellia seed kernel dregs, add 100 ml of hot water, stir for 1 hour, and separate the oil layer After mixing with the water layer, add water to the residue, add 2% alkaline protease (Alcalase 2.4L), enzymatically hydrolyze at 55°C for 3 hours, and separate the oil layer , to merge oil layers and oil layer , 5.5 grams of Mao-camellia oil can be obtained.

[0027] The invention adopts microwave puffing to pretreat raw materials such as camellia seed kernels, which can fully destroy the cell structure of raw materials, and is beneficial to improve the oil yield of oil extraction by subsequent water immersion method; the oil extracted by water after microwave pretreatment belongs to a green and safe production process ; The present invention has the characteristics of simple and environmentally friendly technological process, high oil yield, low investment and easy industrial production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com