Simulation-based parameter optimizing method for precise casting process of single crystal turbine blade

A technology of process parameter optimization and turbine blades, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of poor optimization effect and achieve the effect of improving the optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

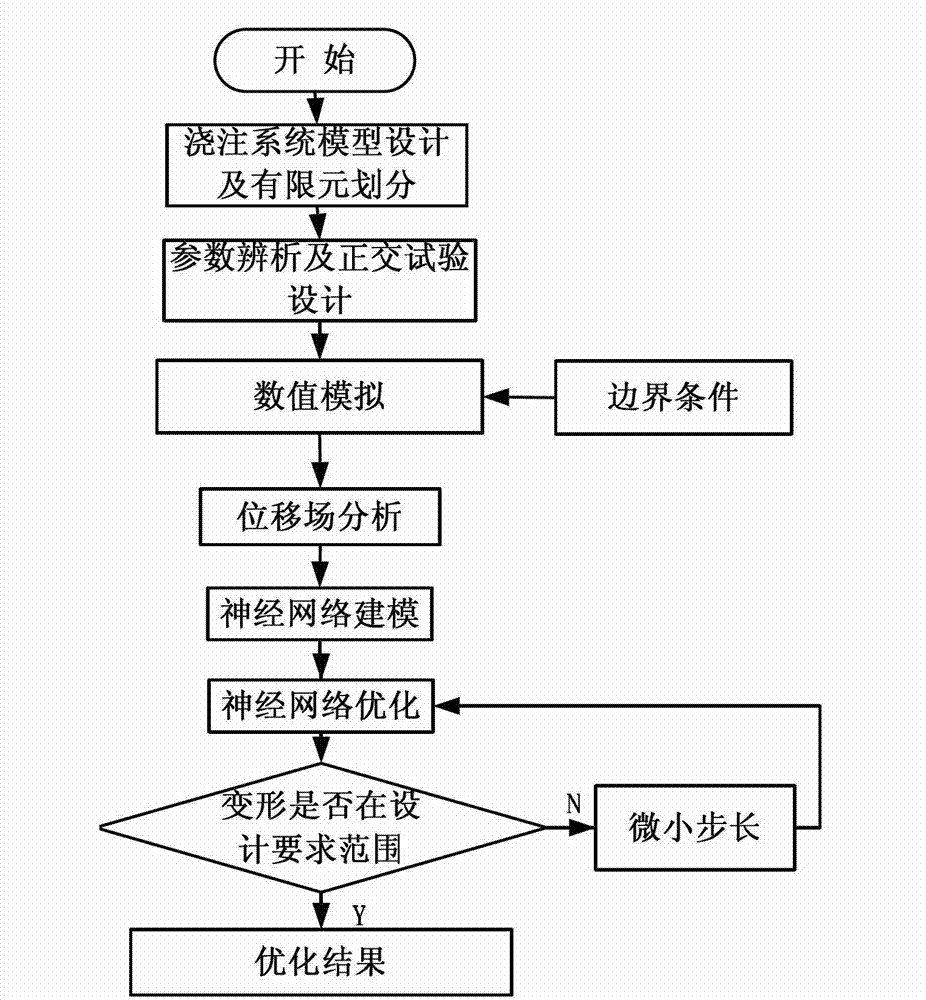

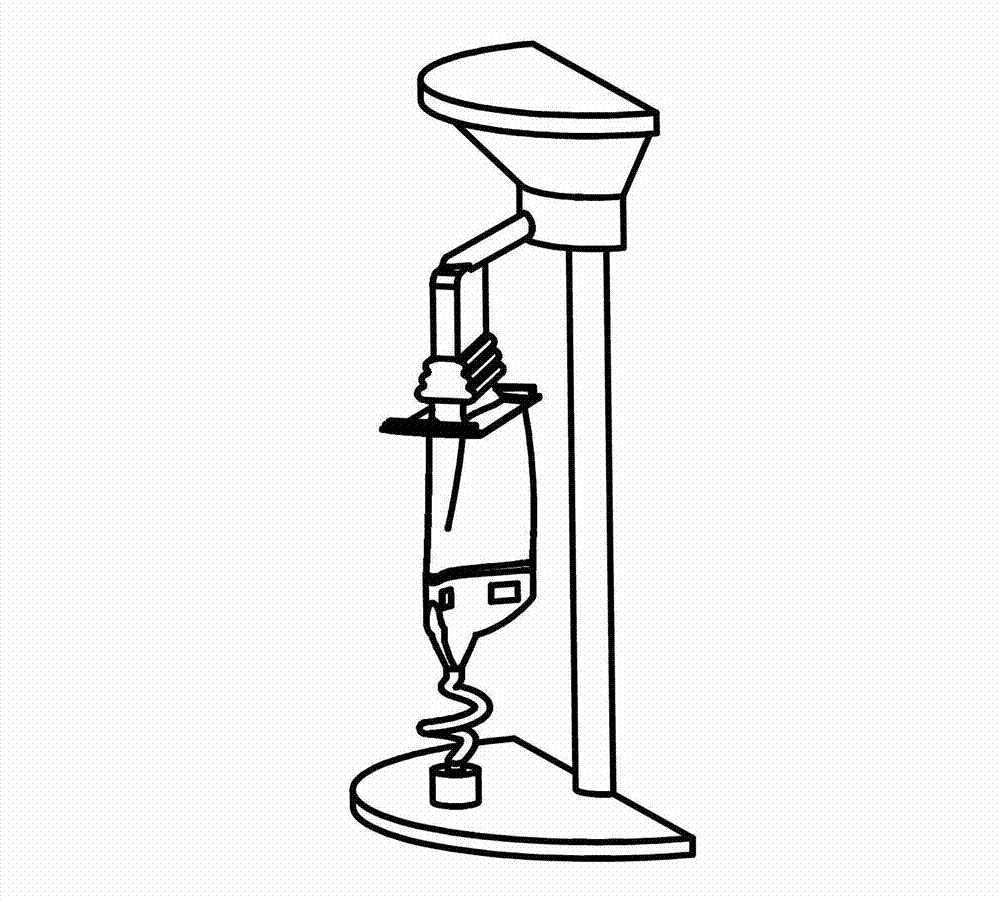

[0033] The following examples refer to Figure 1-7 .

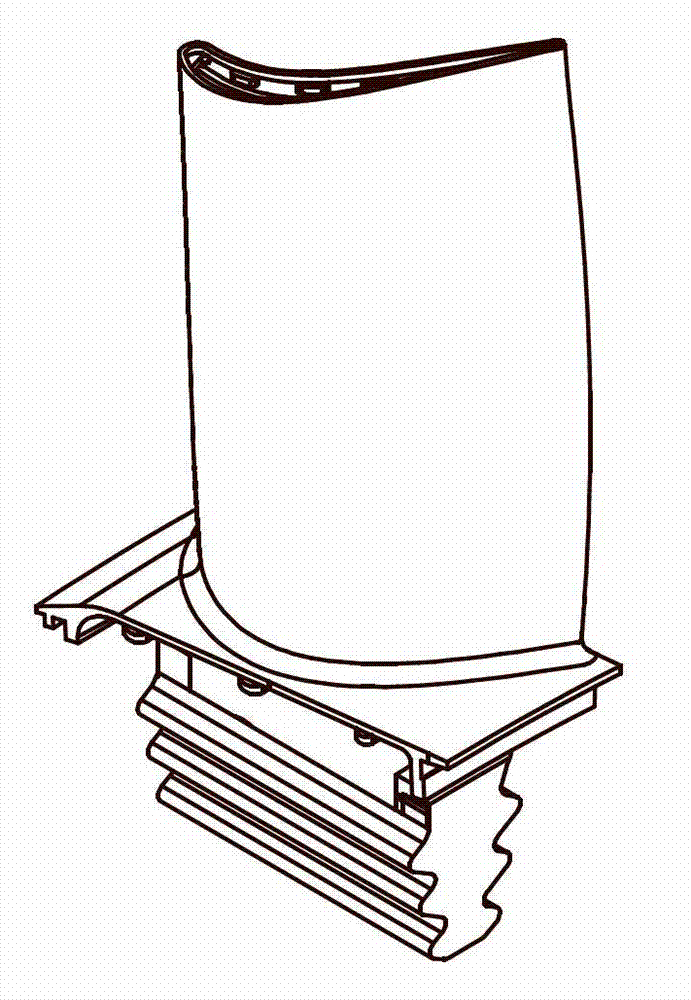

[0034] Step 1: Use a certain type of turbine power blade, the main parameters of which are blade body length 106.10mm, maximum chord length 56.21mm, maximum inscribed circle radius 5.7mm, leading edge radius 4.12mm, and trailing edge radius 1.25mm. The blade is made of the second generation single crystal superalloy DD6, and the mold shell is made of silica sand. According to casting feeding theory and actual production experience, the blade casting process and gating system are designed for power blades, using top injection, 2 pieces in a set.

[0035] Step 2: Use commercial finite element pre-processing software Hypermesh (product of Altair, USA) to divide the model into units based on non-uniform mesh division technology. First, import the gating system model into Hypermesh and discretize it into tetrahedral units. The quality meets the quality requirements of general enterprise finite element analysis. In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com