External tractive lifting-control device and method for offshore cages

A lifting control and traction-type technology, which is applied in the field of additional traction-type offshore marine cage lifting control devices, can solve the problems of easy damage, death or injury, and breeding loss of cage equipment, and achieve the convenience of large-scale promotion and application, Guarantee the effect of production safety and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

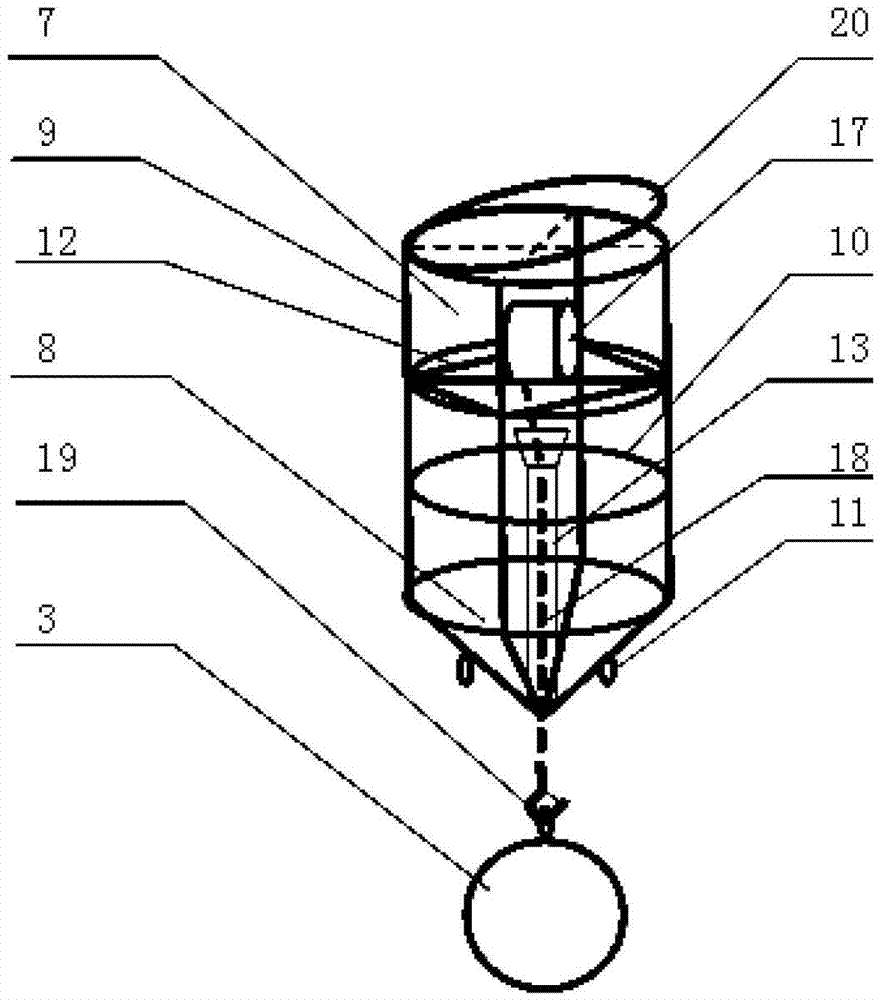

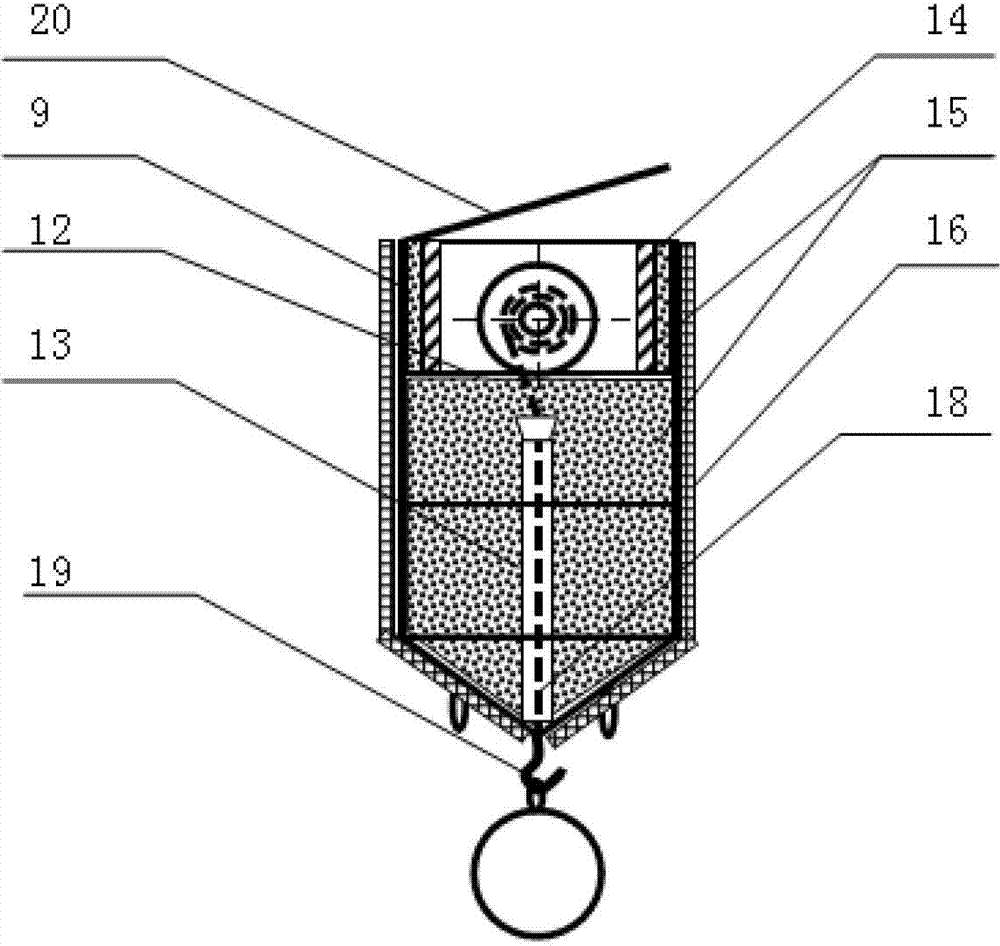

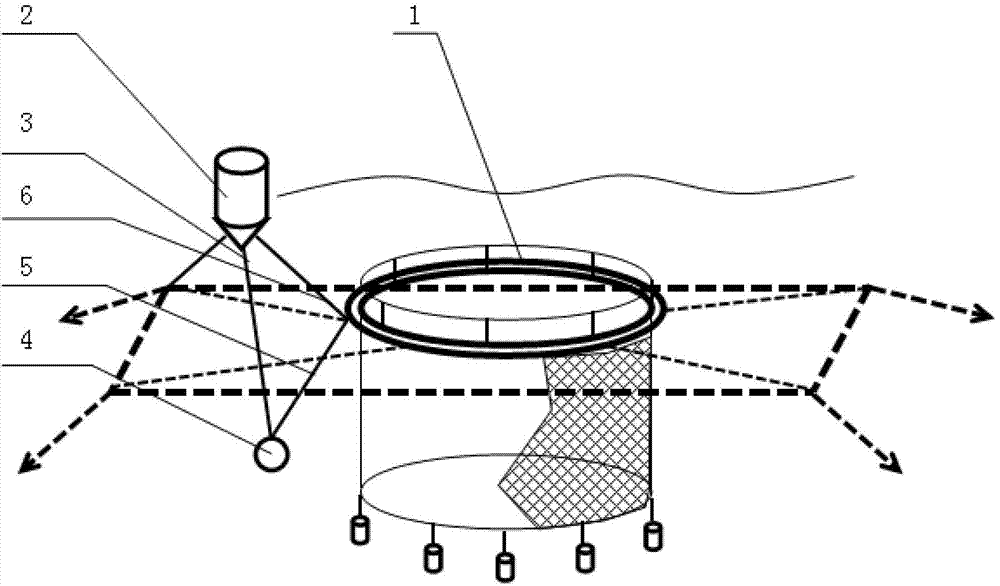

Embodiment 1

[0036] For the original high-density polyethylene double-tube floating offshore marine culture cage with a diameter of 40m and a depth of 8m, the specification of the high-density polyethylene tube used as the buoyancy frame is D250mm (outer diameter) × 10mm (wall thickness), The total length of the high-density polyethylene pipe after the double-pipe welding is about 80m, and its total buoyancy F float = ρ seawater gV, where V = 3.9m 3 , the total buoyancy is about 39kN; the sinker weight of the conventional aquaculture cage is about 7-9kN; the net buoyancy of this specification floating offshore marine aquaculture cage is about 30kN.

[0037] The invention relates to buoys, the diameter of the cylinder is 1000mm, the height is 1500mm, and the bottom surface of the superimposed cone at one end has a diameter of 1000mm and a height of 500mm, each of which has a drainable volume V=1.3m 3 , the buoyancy is about 13kN; a cast iron weight with a weight of 10kN in the water is hung...

Embodiment 2

[0040] Similar to Example 1, for the high-density polyethylene double-tube floating offshore marine culture cage with a diameter of 50m and a depth of 8-10m, the specification of the high-density polyethylene pipe used as the buoyancy frame is D250mm (outside Diameter) × 10mm (wall thickness), the total length of the high-density polyethylene pipe after the double-pipe welding is about 100m, and its total buoyancy is about 49kN; the net buoyancy calculated according to the weight of 9kN counterweight of the conventional culture cage is about 40kN.

[0041] In this implementation example, the diameter of the cylinder and the diameter of the bottom surface of the superimposed cone at one end are both 1200mm (other parameters are the same as in Example 1), and the drainable volume of each is about V=1.9m 3 , the buoyancy is about 19kN; a cast iron weight with a weight of 15kN in water is hung under the buoy. Complete four external hangings that are suspended with weight buoys wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com