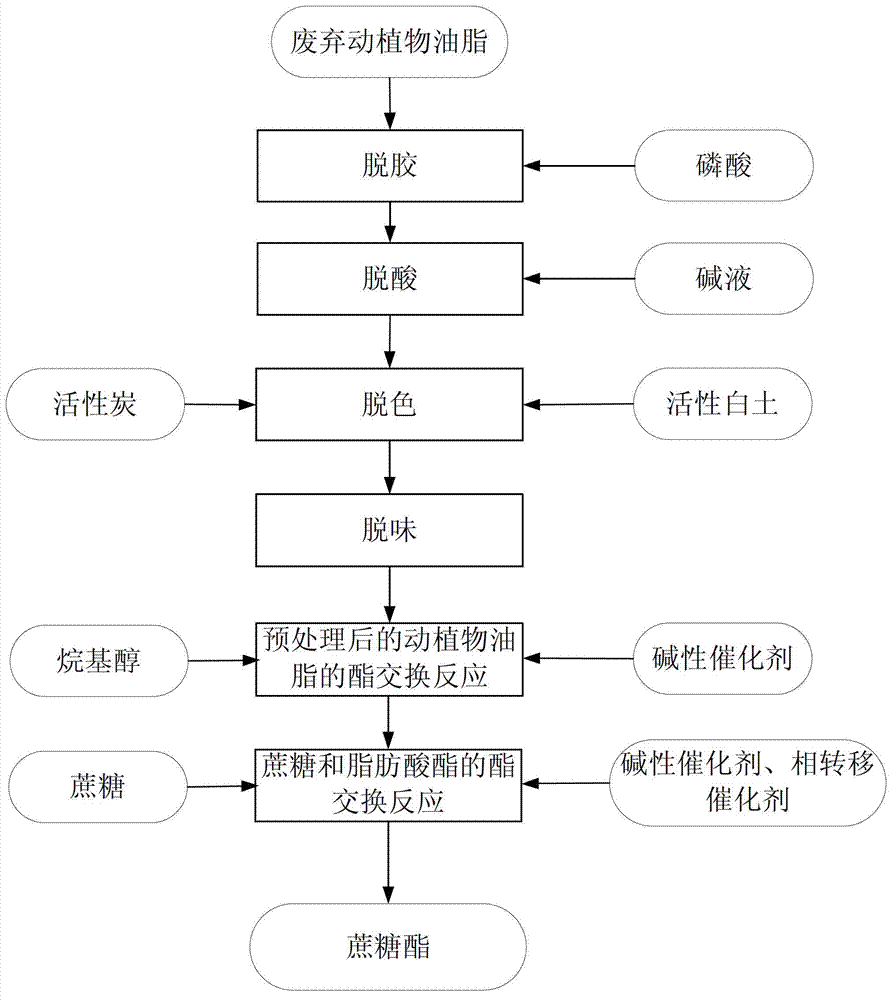

Method for preparing sucrose fatty acid ester through waste plant oil and animal fat

A technology of sucrose fatty acid esters, waste animals and plants, applied in the direction of preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of complex steps, waste of resources, high cost of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Pretreatment of waste animal fats:

[0074] Take 200g of waste animal and vegetable oils (hogwash oil 1, dark yellow in color, acid value 20.8mgKOH / g oil) into a 500ml four-neck flask, add 10g of phosphoric acid with a concentration of 85% into it, heat at 75°C, stir rapidly for 30min, and then Remove the reaction liquid, remove the colloid by high-speed centrifugation, and obtain the degummed oil of the supernatant liquid; add 20 g of sodium hydroxide solution with a mass concentration of 15% to it, heat up to 90 ° C and stir for 1 h, first separate and remove the water phase, and then Centrifuge to remove saponified matter; finally add 3% clay and 0.5% activated carbon, stir continuously at 80°C for 1 hour, and vacuumize under reduced pressure; finally filter to remove activated carbon and clay, and dry to obtain purified oil with light yellow color and acid value 1.09mgKOH / g oil, counted as refined oil 1.

Embodiment 2

[0076] Pretreatment of waste animal fats:

[0077] Take 200g of waste animal and vegetable oils (hogwash oil 2, dark yellow in color, acid value 25.4mgKOH / g oil) into a 500ml four-neck flask, add 10g of phosphoric acid with a concentration of 85% into it, heat at 75°C, stir rapidly for 30min, and then Remove the reaction solution, remove the colloid by high-speed centrifugation, and obtain the supernatant degummed oil; add 30 g of sodium hydroxide solution with a mass concentration of 15% to it, raise the temperature to 90 ° C and stir for 1 hour, first partition the water phase, and then centrifuge Separate and remove the saponified matter; finally add 3% clay and 0.5% activated carbon, stir continuously at 80°C for 1 hour, and vacuumize under reduced pressure; finally filter out activated carbon and clay, and dry to obtain purified oil, light yellow in color and acid value 0.89 mgKOH / g oil, counted as refined oil2.

Embodiment 3

[0079] Pretreatment of waste animal fats:

[0080] Take 200g of waste animal and vegetable oil (gutter oil 1, brown in color, acid value 45.8mgKOH / g oil) into a 500ml four-neck flask, add 10g of phosphoric acid with a concentration of 85% into it, heat at 75°C, stir rapidly for 30min, and then remove The reaction solution was removed by high-speed centrifugation to remove the colloid, and the degummed oil of the supernatant liquid was obtained; 40 g of sodium hydroxide solution with a mass concentration of 15% was added to it, and the temperature was raised to 90 ° C and stirred for 1 hour. The water phase was first partitioned, and then centrifuged. Remove saponified matter; finally add 3% clay and 1% activated carbon, stir continuously at 80°C for 1 hour, and vacuumize under reduced pressure; finally filter out activated carbon and clay, and dry to obtain purified oil with light yellow color and acid value 1.21mgKOH / g oil, calculated as refined oil 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com