High-impedance material, and display substrate black matrix and liquid crystal display apparatus containing same

A high-impedance, black-matrix technology, applied in instruments, coatings, optics, etc., can solve problems such as increased frame width, cost increase, and narrow frame development trends, and achieves the effect of simple preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

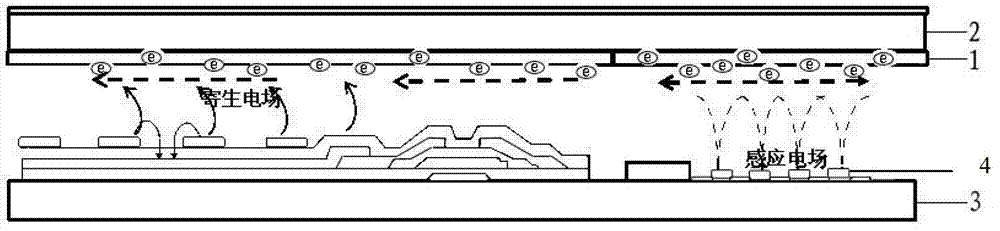

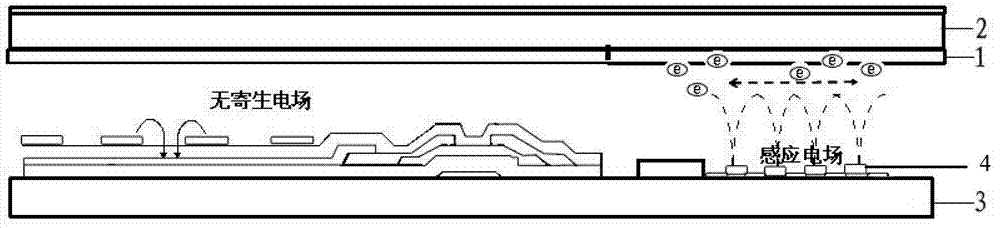

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The composition ratio of the high-resistance material of this embodiment is: 230 g of the sunscreen titanium black, 120 g of the acrylic resin, 648.8 g of the solvent, and 1.2 g of the silane coupling agent bis-3-(aminopropyl)tetramethylsiloxane.

[0056] The specific preparation process is as follows:

[0057] Using a homogenizer, put 230g of titanium black (chemical formula, TiN x O y , X: 0.7 ~ 1.0, y: 0.3 ~ 0.6) (purchased from Mitsubishi Materials Electronics Co., Ltd. titanium black electronic materials), 120g acrylic resin (60% dipentaerythritol hexa (meth) acrylate and 40% diphenoxy A mixture of ethyl alcohol fluorene diacrylate), 648.8g solvent (250g 1,2-propylene glycol methyl ether acetate (PGMEA), 12g ethylene glycol monomethyl ether acetate, 130g ethylene glycol diethyl ether and 256.8g cyclohexane The mixture of ketones) was stirred and dispersed for 1 hour to obtain a pre-dispersion solution. Then, the pre-dispersion solution was added to a grinder filled with...

Embodiment 2

[0061] In addition to 490g titanium black, 208.8g acrylic resin, 300g solvent (117g 1,2-propylene glycol methyl ether acetate (PGMEA), 3g ethylene glycol monomethyl ether acetate 0% to 2%, 60g ethylene glycol diethyl ether And 120g cyclohexanone mixture). The high-resistance material for resin black matrix was formed according to the same method as in Example 1, and a black composition of 49% titanium black for sunscreen and 20.88% for resin was prepared.

[0062] The obtained high-resistance material is coated on the glass by a slit coating method to form a black matrix with a thickness of 1.0um, which can be used in a liquid crystal display device. The tested OD value is 5, the resistivity is 6.5E+14Ω.cm, and it has high optical density and high resistance.

Embodiment 3

[0064] Except for 200 g of titanium black and 30 g of carbon black, the same method as in Example 1 was followed to form a high resistance material for resin black matrix.

[0065] The obtained high-resistance material is coated on the glass by a slit coating method to form a black matrix with a thickness of 1.0um, which can be used in a liquid crystal display device. After testing, the OD value is 3.5, the resistivity is 4.0E+14Ω.cm, and it has high optical density and high resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com