Cutting liquid and preparation method thereof

A technology of cutting fluid and content, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of poor sand-carrying performance, achieve the effect of improving electrical conductivity and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

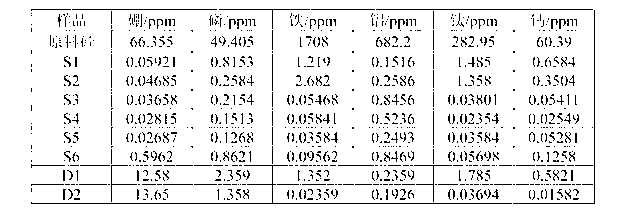

Examples

Embodiment 1

[0033] This example is used to illustrate the cutting fluid disclosed in the present invention and its preparation method.

[0034]100 parts by weight of polyethylene glycol (PEG-400), 2.5 parts by weight of butanol polyoxyethylene ether, 1 part by weight of hydroxyethylethylenediamine, 0.1 part by weight of explosive (Shandong Yunqing Chemical Research Institute) and 0.1 part by weight One part of cyclohexanehexyl hexaphosphonate and 0.1 part by weight of silicone defoamer were added to the mixing tank, the mixer was started, and the mixture was stirred at a speed of 250 rad / min for 40 min. Obtain cutting fluid S1.

Embodiment 2

[0036] This example is used to illustrate the cutting fluid disclosed in the present invention and its preparation method.

[0037] Add 100 parts by weight of polyethylene glycol (PEG-400) into the mixing tank, start the mixer, stir at a speed of 250rad / min for 15 minutes, then add 1.5 parts by weight of polyoxyethylene lauryl ether, and stir for 20 minutes; then add 1 weight Diethylene glycol amine, stirred for 20 minutes; then added 0.1 parts by weight of blasting agent (Shandong Yunqing Institute of Chemical Industry), stirred for 20 minutes; then added 0.1 parts by weight of cyclohexyl hexaphosphonate, stirred for 20 minutes; Silicone defoaming agent, stirred for 30 minutes; cutting solution S2 was obtained.

Embodiment 3

[0039] This example is used to illustrate the cutting fluid disclosed in the present invention and its preparation method.

[0040] Add 100 parts by weight of polyethylene glycol (PEG-400) into the mixing tank, start the mixer, stir at a speed of 250 rad / min for 13 minutes, then add 2 parts by weight of isooctyl alcohol polyoxyethylene ether, and stir for 20 minutes; then add 3 Parts by weight of octylphenol polyoxyethylene ether, stirred for 20 minutes; then added 1 part by weight of triethanolamine, stirred for 20 minutes; then added 0.1 parts by weight of explosive agent (Shandong Yunqing Chemical Research Institute), stirred for 20 minutes; then added 0.1 parts by weight of cyclohexane Hexaol hexaphosphonate was stirred for 20 minutes; then 0.1 parts by weight of silicone defoamer was added and stirred for 30 minutes to obtain cutting fluid S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com