Biomass fuel stove and operational method thereof

A biomass fuel and stove technology, which is used in solid heating fuels, household cooking utensils, household stoves/stoves, etc., can solve the problems of single fuel, inconvenience, and inconvenient movement, and can prevent heat loss, improve service life, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

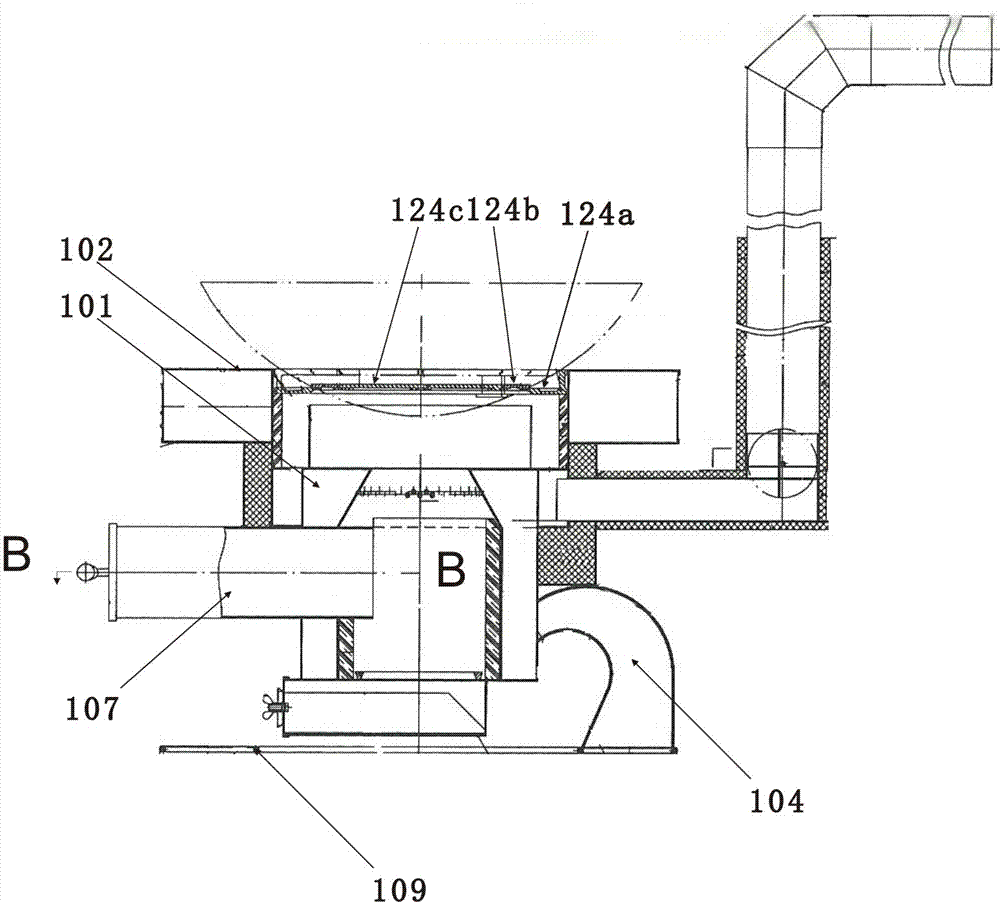

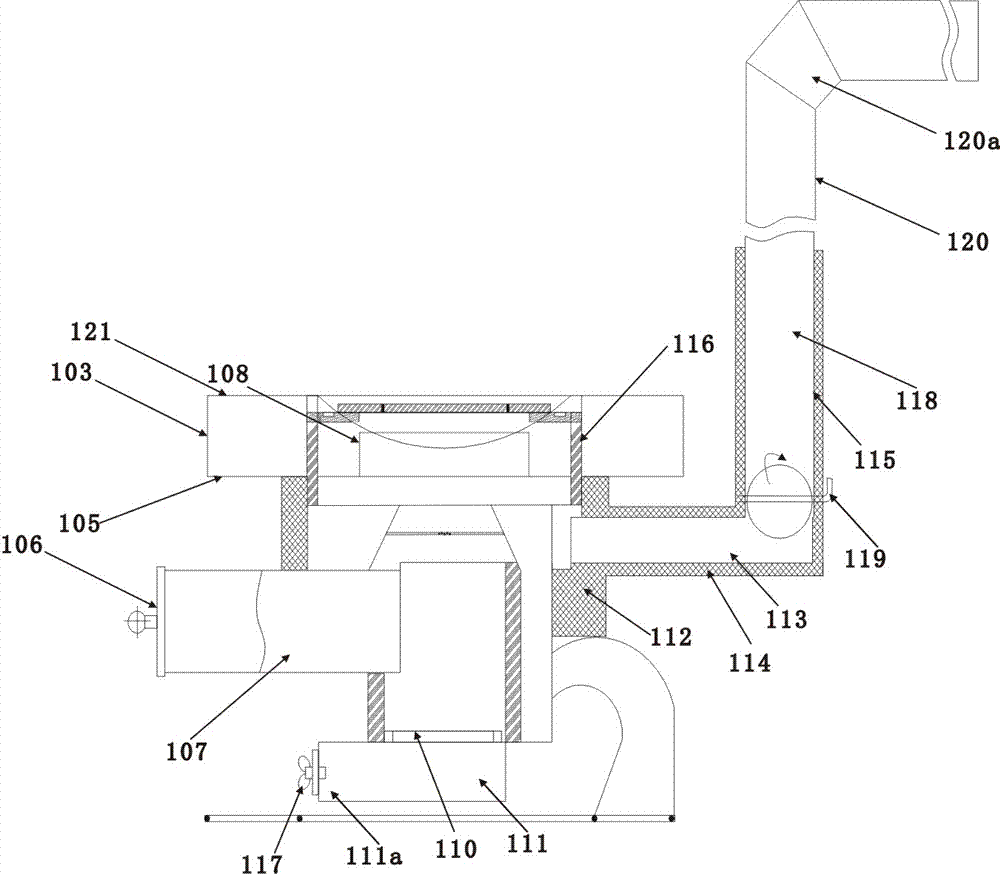

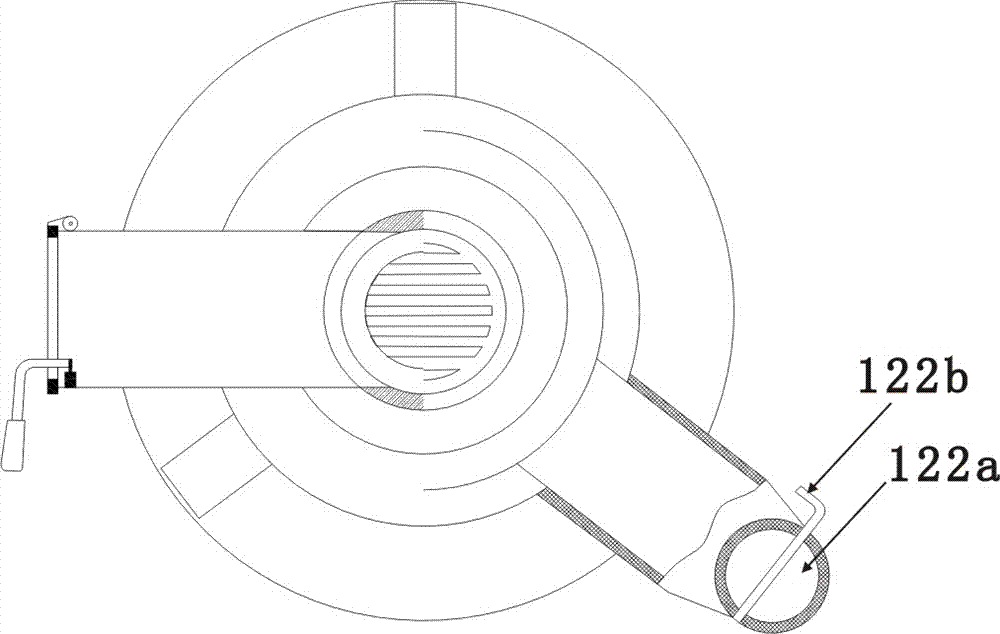

[0032] The purpose of the present invention is to overcome the shortcomings of existing stoves, and to provide a biomass fuel stove with high burnout rate, low emission, simple operation, reliability and safety, and can improve the living environment of ethnic minorities, which is very suitable for it , as shown in the figure: the biomass steel furnace includes a furnace body 101 , a table top 102 , a seat ring 109 , a furnace bridge 110 , an ash chamber 111 , a pot pile 104 and a flue outlet 113 .

[0033] The table top 102 is arranged on the upper end of the furnace body 101, and the furnace body 101 is fixed on the seat ring 109 through the pot pile 104. The pot pile 104 is a curved structure, and the entire furnace body 101 is supported by the pot pile 104. The pot pile 104 of the curved structure It gives the whole biomass steel furnace an aesthetic feeling and reflects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com