Fringe contrast ratio-adjustable large-numerical value bore diameter point-diffraction interference device and method

A fringe contrast, point diffraction interference technology, applied in the field of optical measurement, can solve the problem of difficult to achieve high-precision surface shape detection of large numerical aperture spherical surface, and achieve the effect of simplifying adjustment difficulty and reducing performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

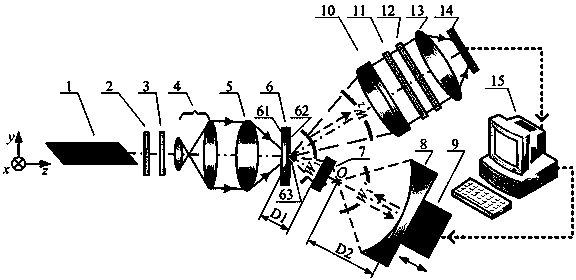

[0028] In the embodiment, the surface shape detection is carried out on a spherical surface 8 with low reflectivity to be measured with a radius of curvature of 500mm, a numerical aperture of 0.35 and a reflectivity of 4%. A linearly polarized laser 1 with an output wavelength λ of 632.8nm is adjusted by a combination of a half-wave plate 2 and the first quarter-wave plate 3 to obtain right-handed circularly polarized light, which is then produced by a collimator beam expander system 4 The parallel light is converged onto the diffraction pinhole 63 of the point diffraction plate 6 by a long working distance microscope objective lens 5 with a magnification of 50×, a numerical aperture of 0.50 and a working distance of 10.6 mm. figure 1 The glass substrate 61 of the midpoint diffraction plate 6 is a quartz glass substrate with a thickness of 0.5 mm; the metal reflective film 62 coated on the glass substrate 61 is a chromium metal film with a thickness of 250 nm; The diffraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com