Process for producing dried onion through dewatering

A production process, a technology for dried onion, applied in the application, food preparation, food science and other directions, can solve the problems of backward technology, low production efficiency, waste, etc., and achieve the effects of improving economic benefits, improving utilization, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

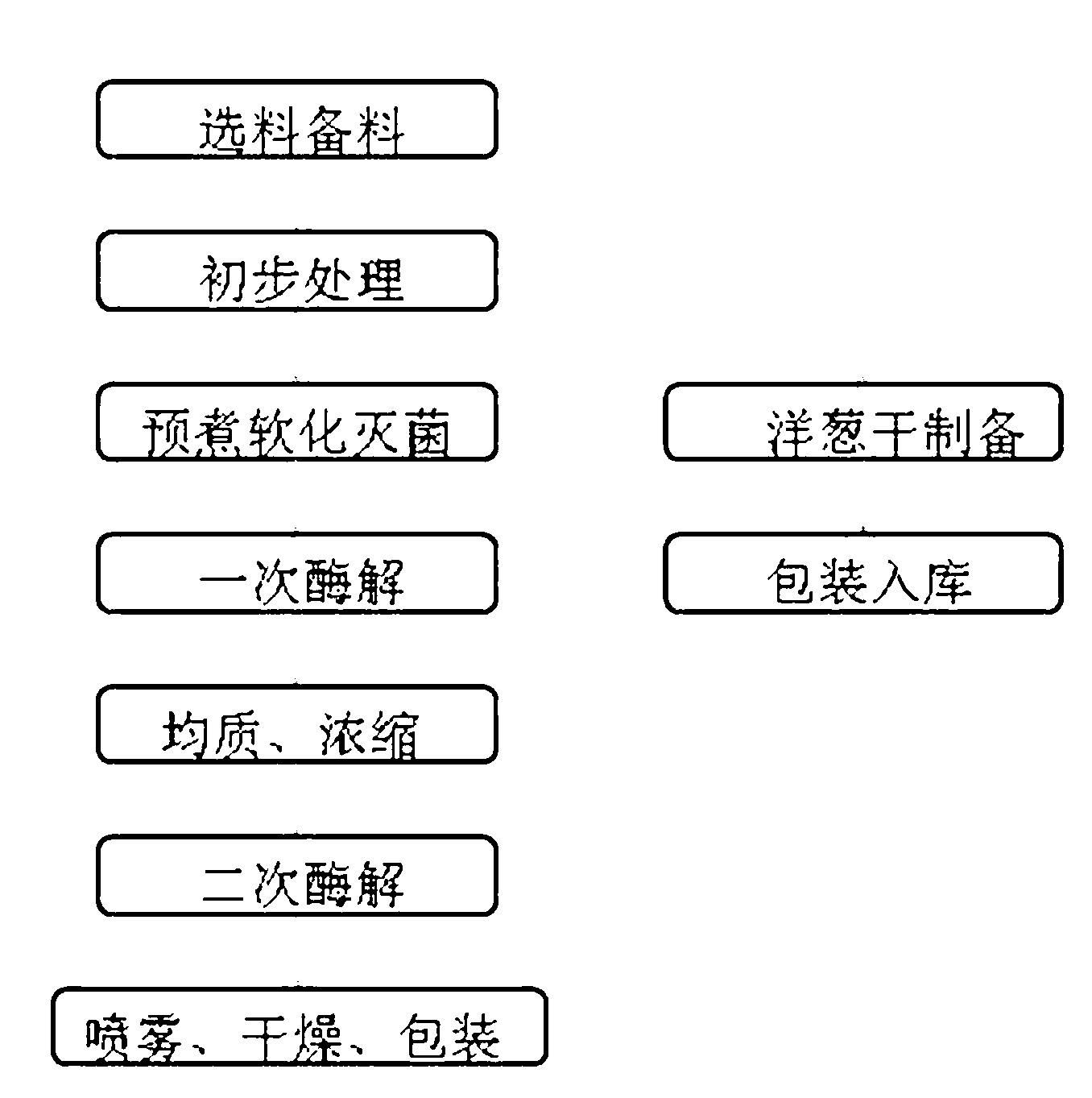

[0018] A kind of dried onion production process as shown in 1, select 300 kilograms of onions without deterioration and mildew, peel them, cut their heads and roots, clean them, dice the cleaned onions, squeeze the juice lightly; select the diced onions after drying , quality inspection, packaging, storage of finished products, and preparation of dried onions.

[0019] Precook the diced onion to soften it, and sterilize it simultaneously. High temperature or ultraviolet light can be used to collect the slurry in the drying step and the slurry in the boiling, softening and sterilization step, and add pectinase and cellulase to it. Enzymatic hydrolysis for 5 minutes, homogenize the material after the first enzymatic hydrolysis, remove the material that has not been treated by the first enzymatic hydrolysis, make the enzymatic hydrolysis rate reach 13%, and then concentrate to the water content of 80%. Cellulase is added to the slurry, and the secondary enzymolysis rate reaches 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com