Gas-filling temperature-raising leaching tank

A technology of leaching tank and heating gas, which is applied in the field of aeration and heating leaching tank, can solve the problems of equipment safety hazards, insufficient anti-swing strength, short service cycle, etc., and achieves improved safety, fast dissolution rate, and improved anti-swing strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

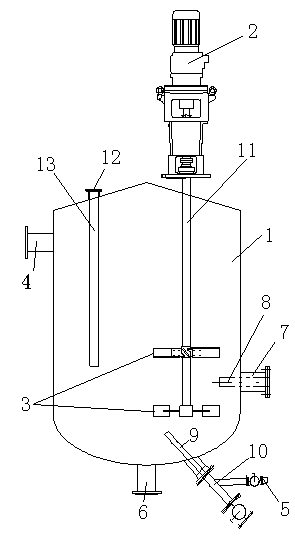

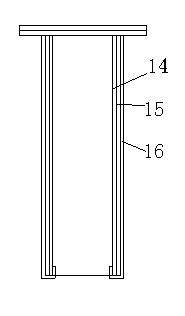

[0040] Manufacture of the heating gas inlet pipe: use a Φ57mm steel pipe to insert a Φ45mm titanium pipe, and line it with rubber to make a rubber-lined titanium-steel composite pipe. Insert the heating device into the groove from the heating flange opening of the groove cover, and heat the gas into the bottom of the pipe. The steam outlet is located in the middle of the height direction of the stirring blade of the leaching tank, and the titanium flange is connected and fixed with the flange of the heating port of the tank cover. The material entering through the feeding nozzle of the leaching tank enters the position between the upper stirring device and the lower stirring device, which enhances the axial circulation capacity and shear dispersion capacity, and accelerates the collision between solid particles of the material and the impact of the liquid flow. Breaking the balance of particle size and liquid film concentration increases the dissolution rate of solid particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com