Reactor and process for preparing iron oxide by utilizing circulation type precipitation method

A technology of precipitation method and reactor, which is applied in the reactor and process field of preparing iron oxide by circular precipitation method, can solve the problems of simple requirements for reaction equipment, achieve uniform reaction degree, facilitate growth control, and prolong residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

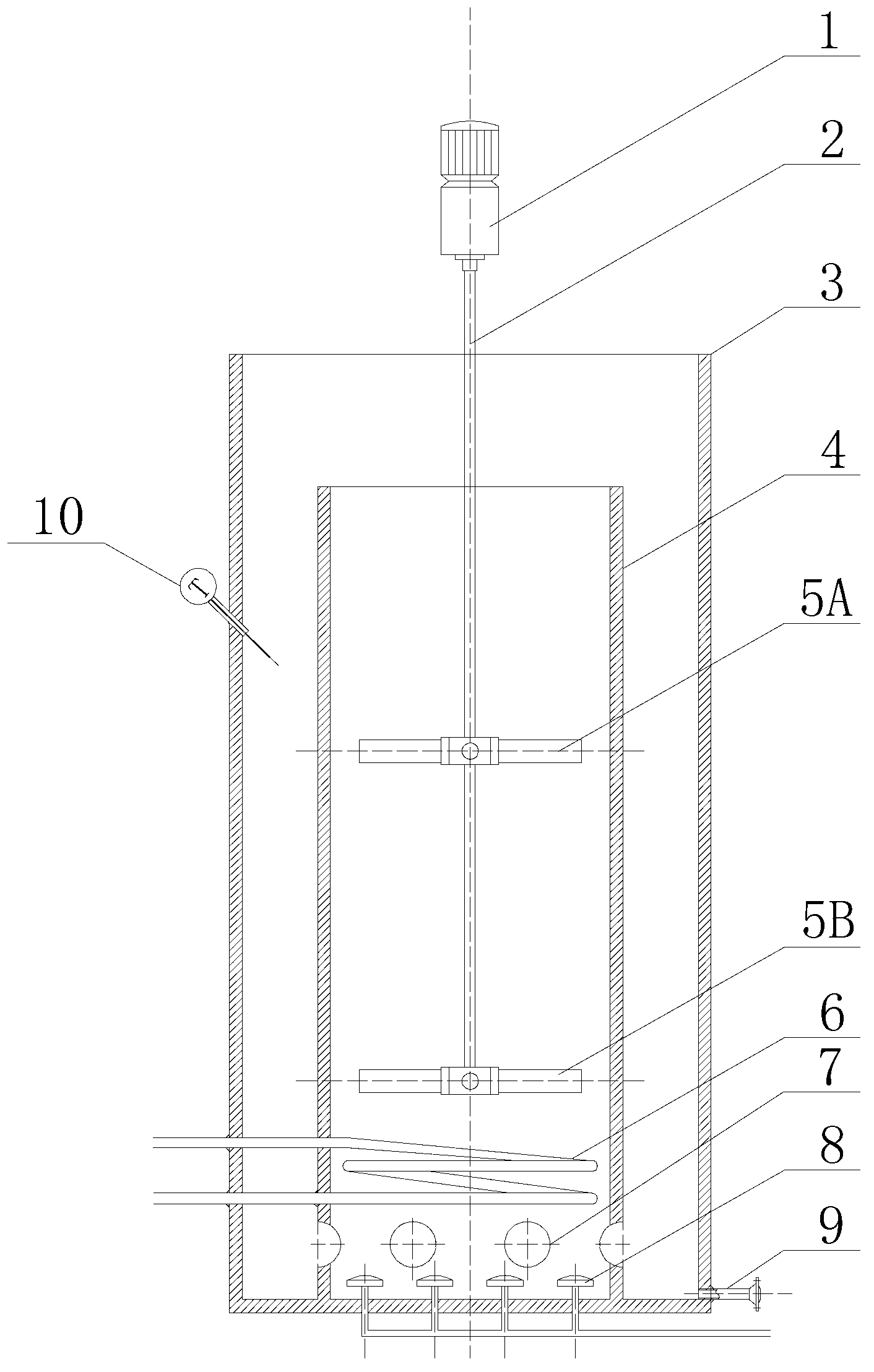

[0016] The structural representation of reactor of the present invention is as figure 1 Shown: a reactor for the preparation of iron oxide by the circulation precipitation method, which is composed of a reaction tank, an inner cylinder, a frequency conversion motor, a main shaft, a stirring paddle, a heating coil, an aeration pan, a sewage outlet and a thermometer; wherein, the reaction tank There is an inner cylinder with a return hole on the lower side of the inner cylinder, a main shaft is installed in the center of the reaction tank, a frequency conversion motor is installed on the top of the main shaft, the first stirring paddle is installed in the middle of the main shaft, the second stirring paddle is installed under the main shaft, and the bottom of the reaction tank is equipped with Aeration pan, the heating coil is installed above the aeration pan, the second stirring paddle is located above the heating coil, the first stirring paddle is located in the middle and uppe...

Embodiment 2

[0020] The structure of the reactor in this embodiment is the same as in Example 1, wherein the height of the reaction tank is 10m, and the height-to-diameter ratio of the reaction tank is 3; the effective height of the inner cylinder is 50cm lower than that of the outer cylinder of the reaction tank; Open area is 1000cm 2 The number of square holes is 10; the diameter ratio of the outer cylinder of the reaction tank to the inner cylinder is 1.2; the material of the reaction tank is 316L stainless steel, and the material of the inner cylinder is titanium.

[0021] Add the reaction raw material ferrous sulfate solution into the reaction tank (the liquid level reaches the top of the inner cylinder), add sodium hydroxide solution to adjust the pH value to 10, feed steam into the heating coil to heat to 90°C, and aeration plate from the bottom of the reaction tank Air is introduced into the middle, the air volume is 10000L / min, the frequency conversion motor is started to drive th...

Embodiment 3

[0023] The structure of the reactor in this embodiment is the same as in Example 1, wherein the height of the reaction tank is 5m, and the height-to-diameter ratio of the reaction tank is 2; the effective height of the inner cylinder is 30cm lower than that of the outer cylinder of the reaction tank; Open area is 250cm 2 The number of round holes is 100; the ratio of the diameter of the outer cylinder of the reaction tank to the inner cylinder is 1.6; the material of the reaction tank is titanium, and the material of the inner cylinder is titanium.

[0024] Add the reaction raw material ferrous sulfate solution into the reaction tank (the liquid level reaches the top of the inner cylinder), add sodium hydroxide solution to adjust the pH value to 9, feed steam into the heating coil to heat to 80°C, and the aeration plate from the bottom of the reaction tank Air is introduced into the middle, the air volume is 4000L / min, the frequency conversion motor is started to drive the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com