Continuous flow aerobe fluidized bed process

An aerobic biological and fluidized bed technology, which is applied in the field of industrial wastewater treatment, can solve the problems of insignificant denitrification and organic matter degradation effect, high capital construction cost and operating cost, troublesome operation and management, etc., and achieve good denitrification and phosphorus removal effect. , The operation effect is stable, the effect of reducing the floor space

Inactive Publication Date: 2012-12-26

LANZHOU UNIVERSITY OF TECHNOLOGY

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These processes have been partially applied in the actual operation process and have achieved certain results, but there are still some problems, such as large tank volume, high infrastructure and operating costs, ineffective denitrification and organic matter degradation, troublesome operation and management, etc.

At present, some scholars have begun to study granulated sludge for wastewater treatment, but this research is mainly limited to the cultivation and domestication in batch SBR reactors. The SBR process has relatively strict control conditions and high management requirements.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

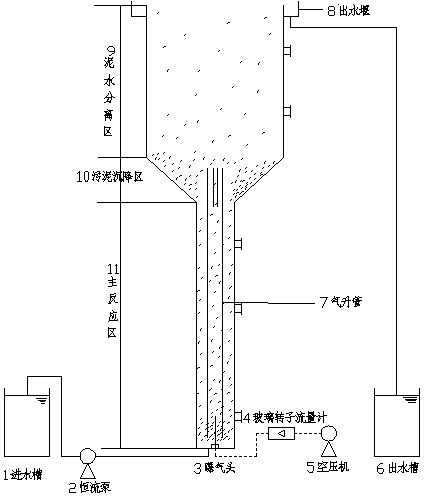

The invention discloses a continuous flow aerobe fluidized bed process, which comprises the following steps of: wastewater is stored in a water inlet groove, and is pumped into the bottom of a reactor through a constant flow pump so as to enter a main reactor; the wastewater is filled into the reactor through aeration of an aeration head at the bottom of an air lift pipe in the reactor; sludge is driven to upwards move in the air lift pipe by the airflow, and is subjected to a downward sedimentation movement in a sludge-water separation region at the upper part of the reactor until the sludge enters into the air lift pipe at the main reaction region at the bottom of the reactor again; the wastewater is full of the reactor, and the sludge with the poor sedimentation property is discharged to a water discharge groove at an effluent weir at the upper part of the reactor along with effluent; the main reaction region of the reactor is fully aerated and is in an aerobic condition, and the wastewater is subjected to nitration reactor; when DO (dissolved oxygen) in the sludge-water separation region of the reactor is relatively insufficient and is in an anaerobic condition, the wastewater is subjected to denitrification reaction, and the effect of denitriding is finally realized; phosphorus can be fully absorbed by polyphosphate accumulation bacteria in the sludge-water separation region of the reactor is relatively insufficient and is in an anaerobic condition under the anaerobic condition and the aerobic condition, the last part of the sludge is discharged along with the effluent, and most of sludge continues to react.

Description

technical field [0001] The invention belongs to waste water treatment technology, in particular to a method for treating industrial waste water with high nitrogen and phosphorus content. Background technique The existing wastewater treatment methods are mainly composed of aerobic, anaerobic and biofilm methods, and in the aerobic method, the activated sludge method and its various evolution processes are the main ones, usually including a. traditional push flow, b. Stage aeration method, c. high load aeration method, d. delayed aeration method, e. adsorption regeneration method, f. complete mixing method, g. deep well aeration method, h. pure oxygen aeration method, i. Kraus method, j.AB method, k.SBR method, l. oxidation ditch, m. circulating activated sludge process, etc. These processes have been partially applied in the actual operation process and have achieved certain results, but there are still some problems, such as large tank volume, high infrastructure and oper...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F3/30

Inventor 赵霞冯辉霞王晓春雒和明张建强姜峰赵阳雨孔秀琴张庆芳

Owner LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com