Degradable liquid mulching film and production method thereof

A technology of liquid mulch and aqueous solution, which is applied in the direction of chemical instruments and methods, organic fertilizers, fertilizer mixtures, etc., can solve the problems that affect the ability of soil water and fertilizer retention, low cross-linking degree, and reduced yield, so as to improve crop quality, The effect of solving white pollution and inhibiting water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

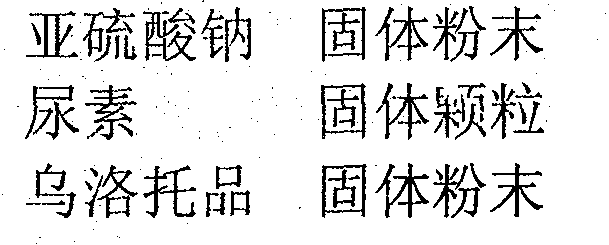

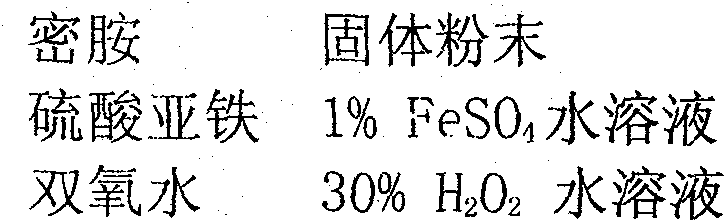

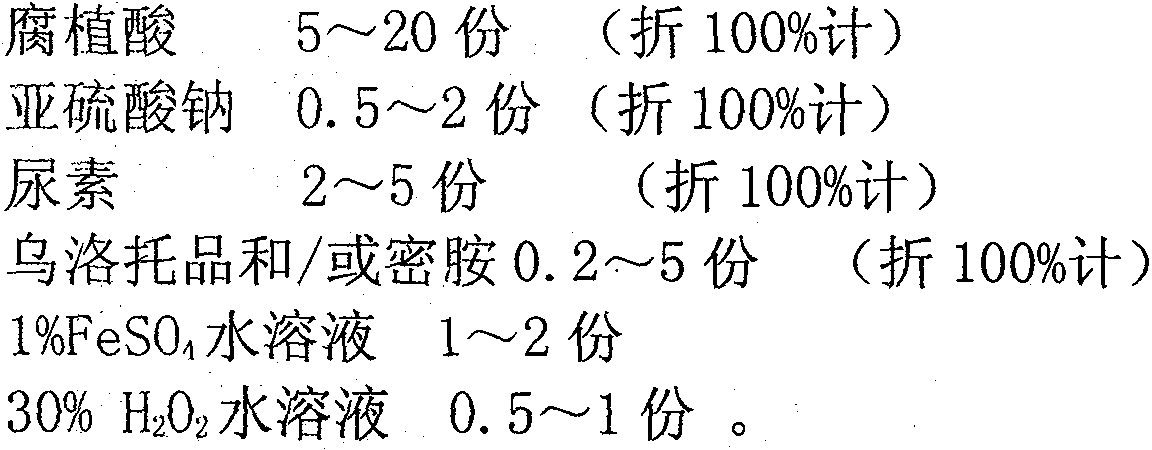

[0054] Liquid mulch raw material composition:

[0055]

[0056] Liquid mulch manufacturing method:

[0057] (1) Get 100 parts of straw papermaking black liquor (calculated on a 100% dry basis), and react with 5 parts of humic acid (calculated by 100%) under stirring for 40 minutes at a temperature of 90° C. and normal pressure. Neutralize the residual alkaline substances in papermaking black liquor, and simultaneously produce crosslinking and copolymerization reactions;

[0058] (2) Add Na to the above reaction solution 2 SO 3 0.5 parts (100% calculation), at a temperature of 90°C, stirred and reacted for 30 minutes to carry out sulfonation reaction;

[0059] (3) At a temperature of 45°C, add 2 parts of urea and 1.5 parts of melamine (100% calculation) to the above reaction solution, and stir thoroughly for 15 minutes; then lower the temperature to 25°C, and add 1% FeSO 4 1 part of aqueous solution, 30% H 2 o 2 0.5 part of aqueous solution, initiate grafting and copol...

Embodiment 2

[0062] Liquid mulch raw material composition:

[0063]

[0064] Liquid mulch manufacturing method:

[0065] (1) Take 100 parts of straw cooking slurry (calculated on a 100% dry basis), and react with 10 parts of humic acid (calculated by 100%) at a temperature of 80°C and normal pressure for 50 minutes under stirring, Neutralize the residual alkaline substances in papermaking black liquor, and simultaneously produce crosslinking and copolymerization reactions;

[0066] (2) Add Na to the above reaction solution 2 SO 3 1 part (100% calculation), stirred and reacted at a temperature of 80° C. for 30 minutes, and carried out sulfonation reaction;

[0067] (3) Add 2 parts of urea and 1 part of urotropine (100% calculation) to the above reaction solution at 40°C, and stir thoroughly for 15 minutes; then lower the temperature to 20°C, and add 1% FeSO 4 1.5 parts of aqueous solution, 30% H 2 o 2 0.8 parts of the aqueous solution, initiate the copolymerization reaction and con...

Embodiment 3

[0070] Liquid mulch raw material composition:

[0071]

[0072] Liquid mulch manufacturing method:

[0073] (1) Get 100 parts of straw papermaking black liquor (calculated on a 100% dry basis), and react with 15 parts of humic acid (calculated by 100%) under stirring for 60 minutes at a temperature of 100° C. and normal pressure. Neutralize the residual alkaline substances in papermaking black liquor, and simultaneously produce crosslinking and copolymerization reactions;

[0074] (2) Add Na to the above reaction solution 2 SO 3 2 parts (100% calculation), stirred and reacted at a temperature of 80° C. for 30 minutes, and carried out sulfonation reaction;

[0075] (3) Add 4 parts of urea, 2 parts of urotropine and 3 parts of melamine (100% calculation) to the above reaction solution at 50°C, stir thoroughly for 15 minutes; then lower the temperature to 30°C, add 1% FeSO 4 2 parts of aqueous solution, 30% H 2 o 2 1 part of aqueous solution, initiate grafting, copolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com