Dry preparation method of high-temperature resistant nanometer micropore thermal insulation board

A nano-microporous, high-temperature-resistant technology, which is applied in the field of dry preparation of high-temperature-resistant nano-microporous heat insulation boards, can solve the problems of vacuum layer damage, high thermal conductivity, and high temperature resistance, and achieve low heating permanent line variation coefficient , The production process is simple, and the effect of high temperature resistance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

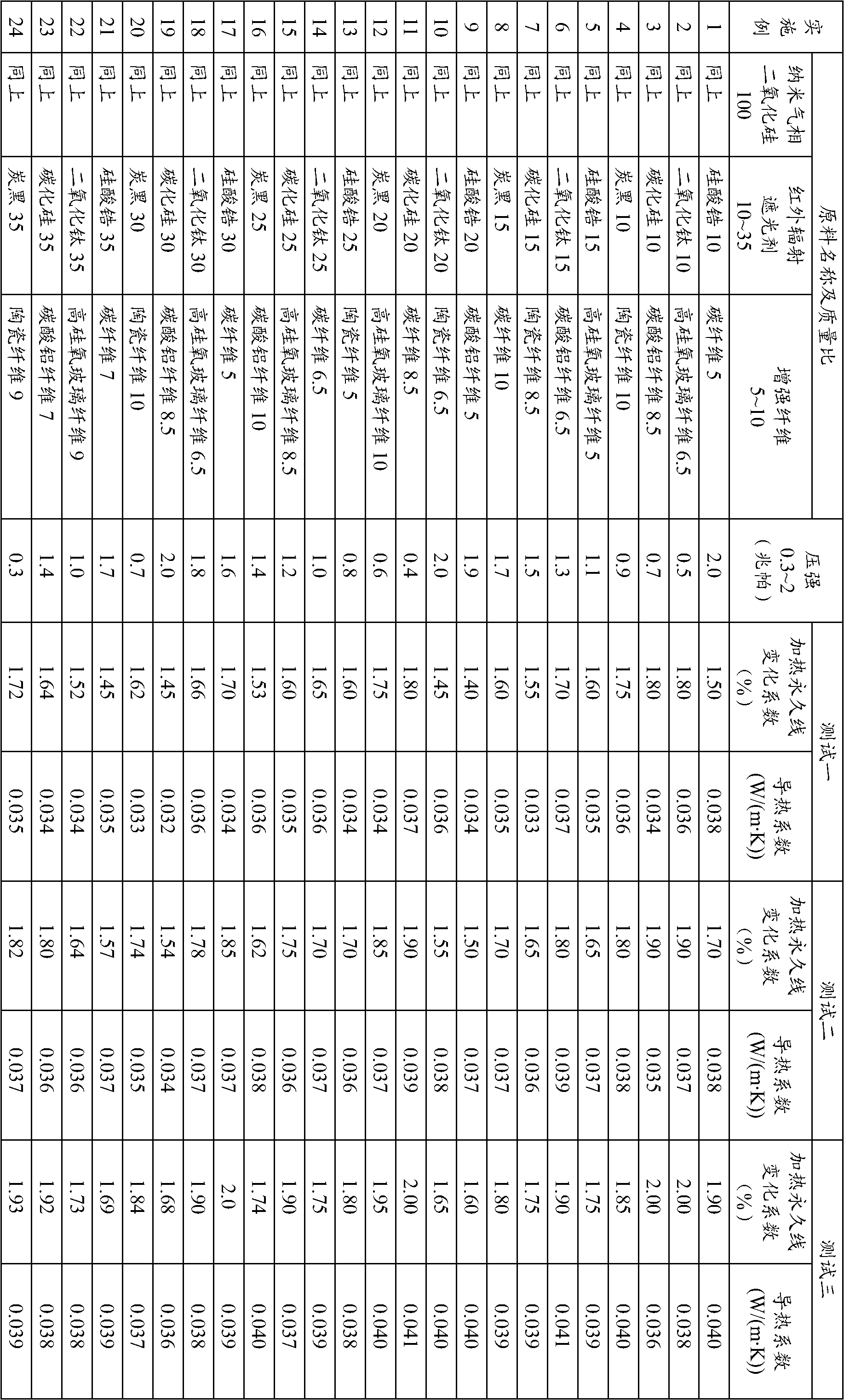

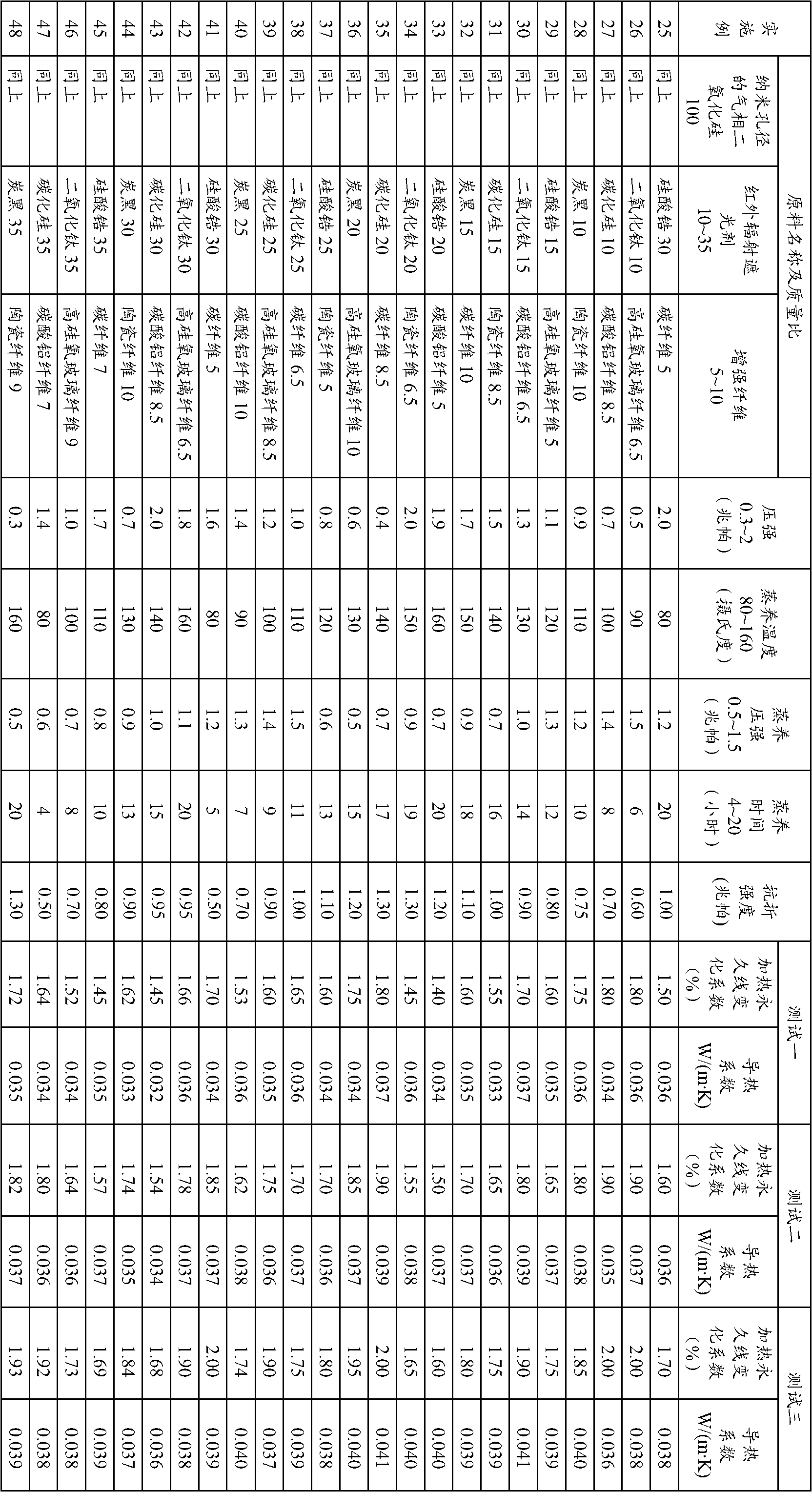

Examples

Embodiment 1

[0017] Put nano fumed silicon dioxide, infrared radiation opacifier and reinforcing fiber into the mixer in the ratio of 100:10:5 (mass ratio) in sequence, and mix evenly to obtain the mixture. Open the feed valve of the mixer, and the mixture enters the silo. The mixture in the silo is transferred to the mold in the press by vacuum extraction. After the mixture is filled with the mold, the mixture is pressed with a pressure of 2 MPa, and the core material is obtained after compression molding. The core material is wrapped in high-silica glass fiber cloth to obtain a high-temperature resistant nano-microporous heat insulation board.

[0018] In this embodiment, zirconium silicate is used as the infrared radiation shielding agent. In other embodiments, titanium dioxide, silicon carbide or carbon black can also be used as the infrared radiation shielding agent.

[0019] In this embodiment, carbon fibers are used as reinforcing fibers. In other embodiments, the reinforcing fi...

Embodiment 25

[0026] The fumed silicon dioxide with nano-pore size, infrared radiation opacifying agent and reinforcing fiber are sequentially put into the mixer in the ratio (mass ratio) of 100:30:5, and the mixture is obtained after stirring evenly. Open the feed valve of the mixer, and the mixture enters the silo. The mixture in the silo is transferred to the mold in the press by vacuum extraction. After the mixture is filled with the mold, the mixture is pressed with a pressure of 2 MPa, and the core material is obtained after compression molding. The core material is placed in an autoclave whose temperature is set to 80 degrees Celsius and whose pressure is set to 1.2 MPa, and steamed for 20 hours. Put the steam-cured core material into high-silica glass fiber cloth for wrapping to obtain a high-temperature-resistant nano-microporous heat insulation board. After placing the high-temperature-resistant nano-microporous heat insulation board in an environment of 800 degrees Celsius for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com