Hydraulic driving system for hydraulic driving bottom shaft rotating steel dam valve

A technology of drive system and hydraulic system, applied in fluid pressure actuation system components, fluid pressure actuation devices, hydraulic engineering and other directions, can solve the problems of high cost, heavy operation and maintenance work, unsatisfactory synchronization effect, etc. Easy to manufacture, high degree of automation and reliability, good economic benefits and social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

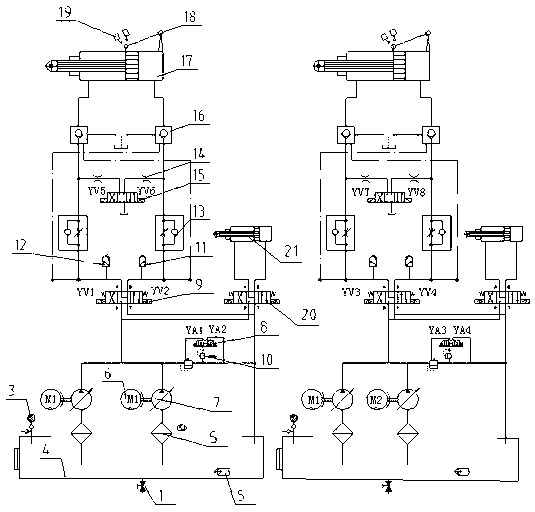

[0012] Such as figure 1 As shown, the hydraulic drive system of hydraulically driven bottom shaft rotating steel dam gate includes electrical control system and hydraulic system; electrical control system includes programmable logic controller PLC, man-machine interface, expansion machine and remote centralized control interface; man-machine interface, expansion Both the machine and the remote centralized control interface are connected with the programmable controller PLC.

[0013] The hydraulic system includes a left hydraulic system and a right hydraulic system with the same structure on both sides of the steel dam gate. The left hydraulic system includes a hydraulic cylinder 17 and a locking hydraulic cylinder 21 . Both the hydraulic cylinder 17 and the locking hydraulic cylinder 21 are connected to the same oil tank 4 through respective oil passages. The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com