Wafer level chip scale package (WLCSP) single chip packaging piece and plastic packaging method thereof

A packaging method and packaging technology, which is applied in the direction of electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of high cost, complicated WLCSP manufacturing process, and extremely high precision requirements for electroplating and photolithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

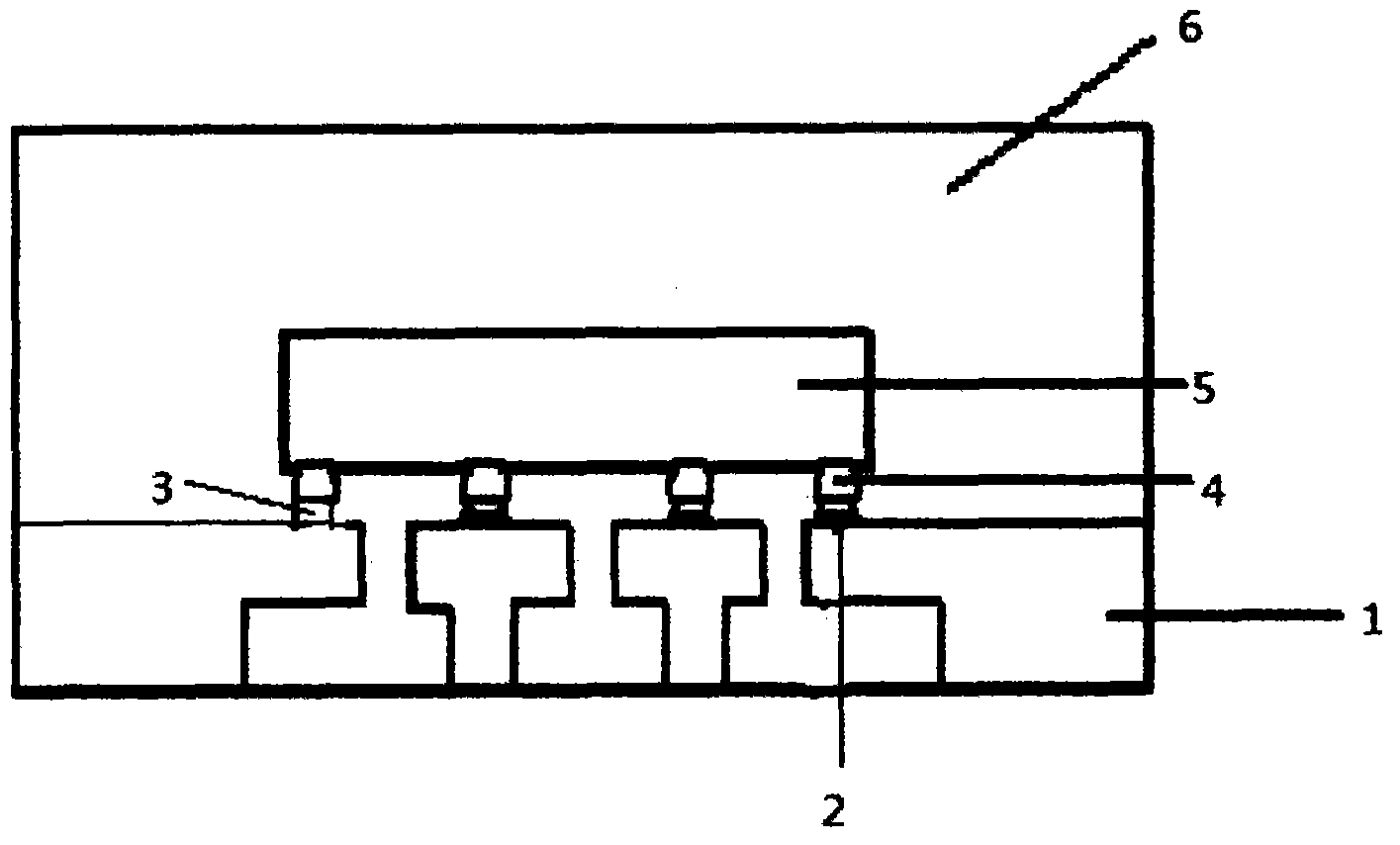

[0037] A WLCSP single-chip package, plated with Au or Cu metal bumps 4 and a tin layer 2, its packaging method: follow the steps below:

[0038] The first step, wafer thinning;

[0039] The thinned thickness of the wafer is 50μm, and the roughness Ra is 0.10mmmm;

[0040] The second step is to plate metal bumps;

[0041] Plating metal bumps 4 on the surface of metal Au in the chip nip area on the entire wafer;

[0042] The third step, scribing;

[0043] For wafers with a thickness below 150 μm, use a double-knife dicing machine and its process;

[0044] The fourth step is to tin-plate the corresponding area of the frame;

[0045] A layer of 2um tin layer 2 is plated on the corresponding area of the PAD on the pin 1 in the frame;

[0046] The fifth step, core;

[0047] Turn the IC chip 5 upside down, and weld the metal bumps 4 on the IC chip 5 to the frame by using the Flip-Chip process;

[0048] The sixth step, reflow soldering;

[0049] Using the reflow soldering ...

Embodiment 2

[0053] A WLCSP single-chip package, coated with Cu metal bumps 4 and tin layer 2, its packaging method: follow the steps below:

[0054] The first step, wafer thinning;

[0055] The thickness of wafer thinning is 130μm, and the roughness Ra is 0.20mm;

[0056] The second step is to plate metal bumps;

[0057] Plating metal bumps 4 on the metal Cu surface of the chip nip area on the entire wafer;

[0058] The third step, scribing;

[0059] For wafers with a thickness below 150 μm, use a double-knife dicing machine and its process;

[0060] The fourth step is to tin-plate the corresponding area of the frame;

[0061] A layer of 25um tin layer 2 is plated on the corresponding area of PAD on pin 1 in the frame;

[0062] The fifth step, core;

[0063]Turn the IC chip 5 upside down, and weld the metal bumps 4 on the IC chip 5 to the frame by using the Flip-Chip process;

[0064] The sixth step, reflow soldering;

[0065] Using the reflow soldering process after SMT, afte...

Embodiment 3

[0069] A WLCSP single-chip package, plated with Au or Cu metal bumps 4 and a tin layer 2, its packaging method: follow the steps below:

[0070] The first step, wafer thinning;

[0071] The thickness of wafer thinning is 200μm, and the roughness Ra is 0.30mm;

[0072] The second step is to plate metal bumps;

[0073] Plating metal bumps 4 on the surface of metal Al or Cu in the chip nip area on the entire wafer;

[0074] The third step, scribing;

[0075] Wafers above 150μm adopt ordinary dicing process;

[0076] The fourth step is to tin-plate the corresponding area of the frame;

[0077] A layer of 50um tin layer 2 is plated on the corresponding area of PAD on pin 1 in the frame;

[0078] The fifth step, core;

[0079] Turn the IC chip 5 upside down, and weld the metal bumps 4 on the IC chip 5 to the frame by using the Flip-Chip process;

[0080] The sixth step, reflow soldering;

[0081] Using the reflow soldering process after SMT, after tin melting treatment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com