Preparation method of Co3O4/graphene nanocomposite material

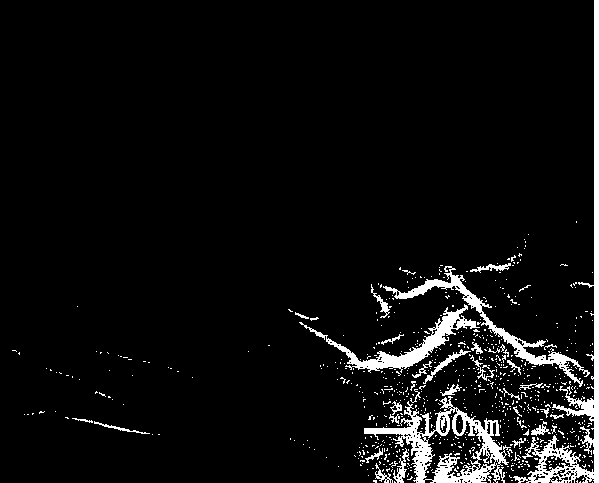

A nano-composite material and graphene technology, which is applied in the field of preparation of Co3O4/graphene composite materials, can solve problems that have not been reported before, and achieve the effect of small particle size, novel material and uniform compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

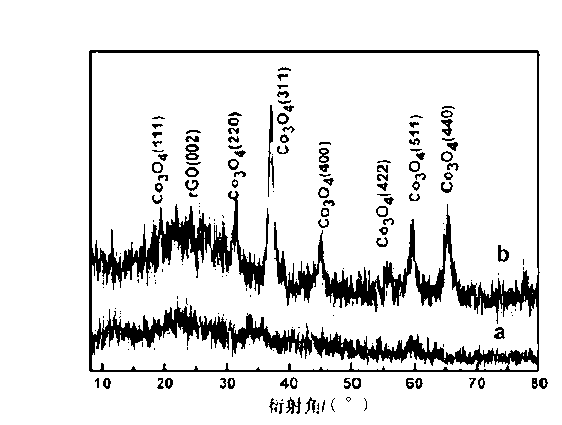

[0025] Preparation of Co from Cobalt Chloride 3 o 4 / graphene nanocomposite material, its process and steps are as follows:

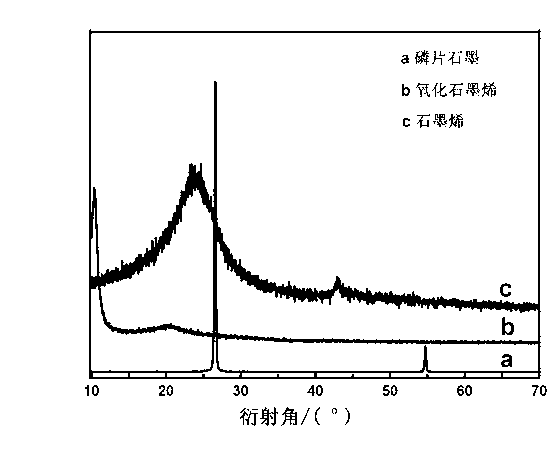

[0026] (1) Preparation of graphene oxide solution: the traditionally known Hummers chemical graphite oxide method is adopted. The specific process is as follows: 100mL of 98% H 2 SO 4 Add to 2.0g KNO 3 and 4.0g graphite, after mixing and stirring for 30min, slowly add 15g KMnO 4 . Afterwards, the temperature of the system was raised to 35±3°C, and the reaction was carried out at this temperature for 2 hours. Then dropwise add 180mLH 2 O, after adding H dropwise 2 The process of O will increase the temperature to close to 100°C, after stirring at this temperature for 30min, add 14mL 30% H 2 o 2 to remove excess KMnO 4 , and finally with 500mL 3% HCl and a large amount of H 2 O was washed, centrifuged, and vacuum-dried to obtain graphite oxide. Graphite oxide was ultrasonically dispersed in deionized water to prepare a 1 mg / mL graphene oxid...

Embodiment 2

[0031] Preparation of Co from cobalt nitrate 3 o 4 / graphene nanocomposite material, its process and steps are as follows:

[0032] (1) Preparation of graphene oxide solution: the traditionally known Hummers chemical graphite oxide method is adopted. The specific process is as follows: 100mL of 98% H 2 SO 4 Add to 2.0g KNO 3 and 4.0g graphite, after mixing and stirring for 30min, slowly add 15g KMnO 4 . Afterwards, the temperature of the system was raised to 35±3°C, and the reaction was carried out at this temperature for 2 hours. Then dropwise add 180mLH 2 O, after adding H dropwise 2 The process of O will increase the temperature to close to 100°C, after stirring at this temperature for 30min, add 14mL 30% H 2 o 2 to remove excess KMnO 4 , and finally with 500mL 3% HCl and a large amount of H 2 O was washed, centrifuged, and vacuum-dried to obtain graphite oxide. Graphite oxide was ultrasonically dispersed in deionized water to prepare a 1 mg / mL graphene oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com