Electric bus power replacing robot system and method

A battery swapping robot and electric bus technology, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of small range of freedom, small relative displacement, slow moving speed, etc., to reduce space occupancy rate, relatively The effect of small displacement and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

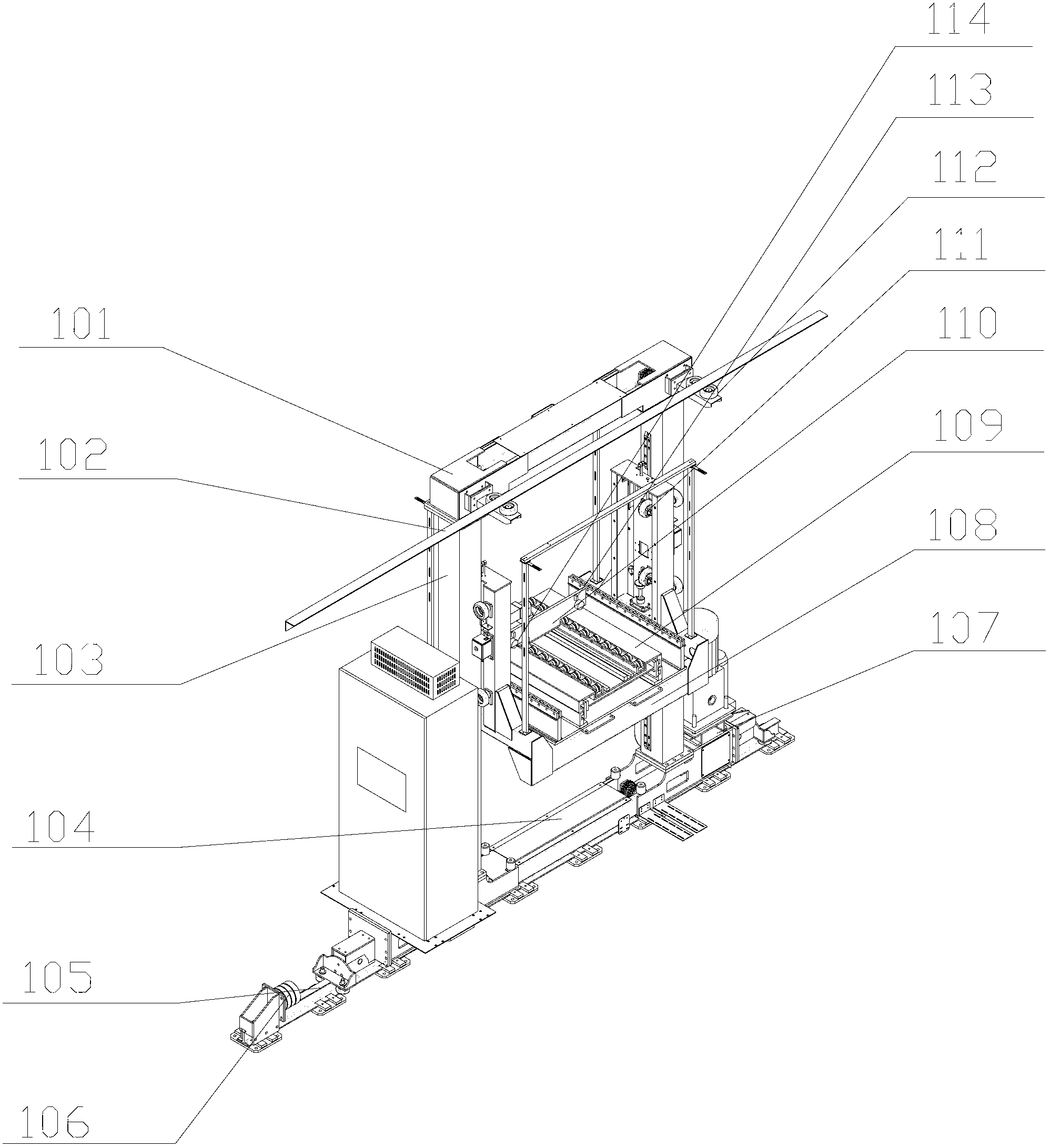

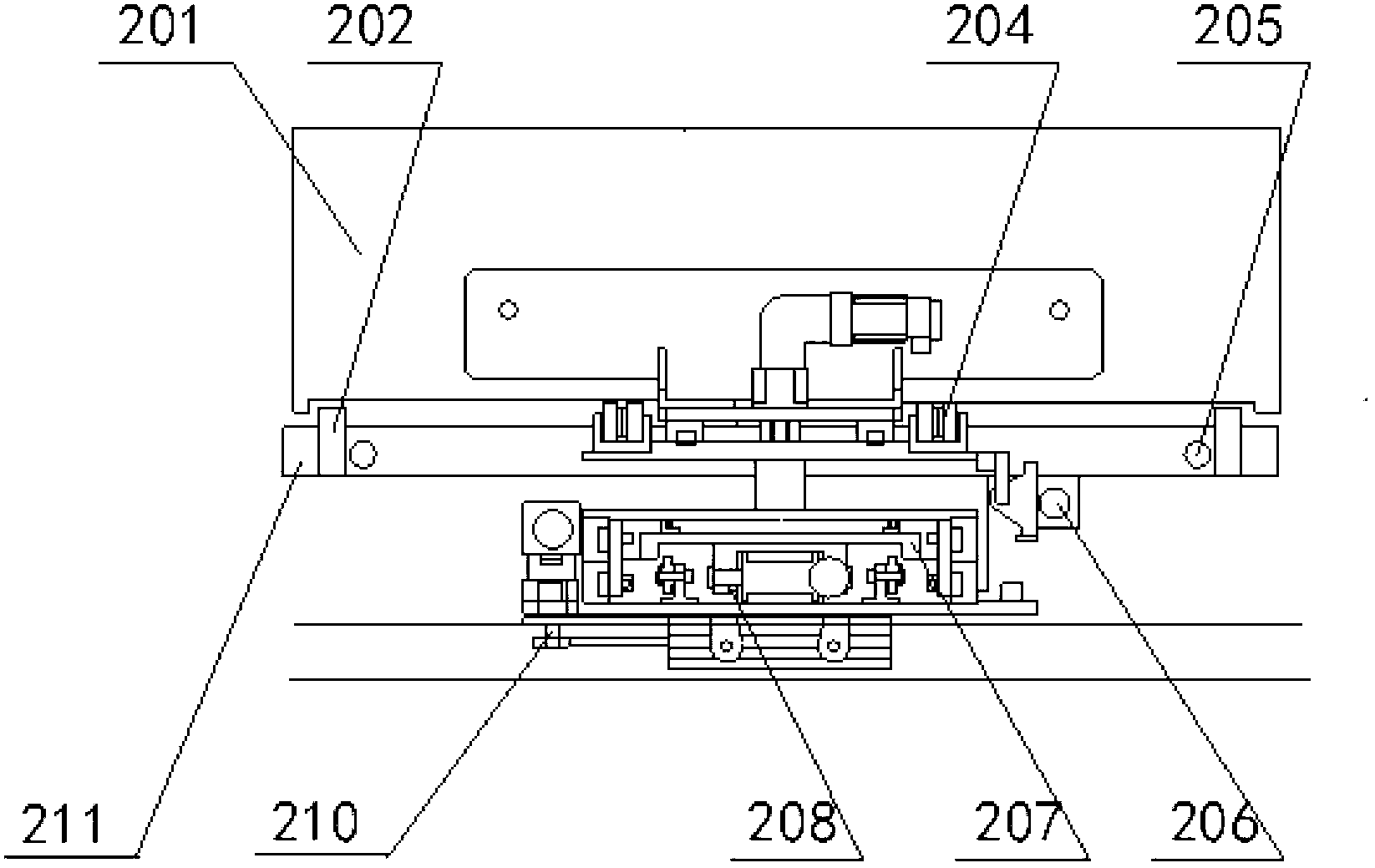

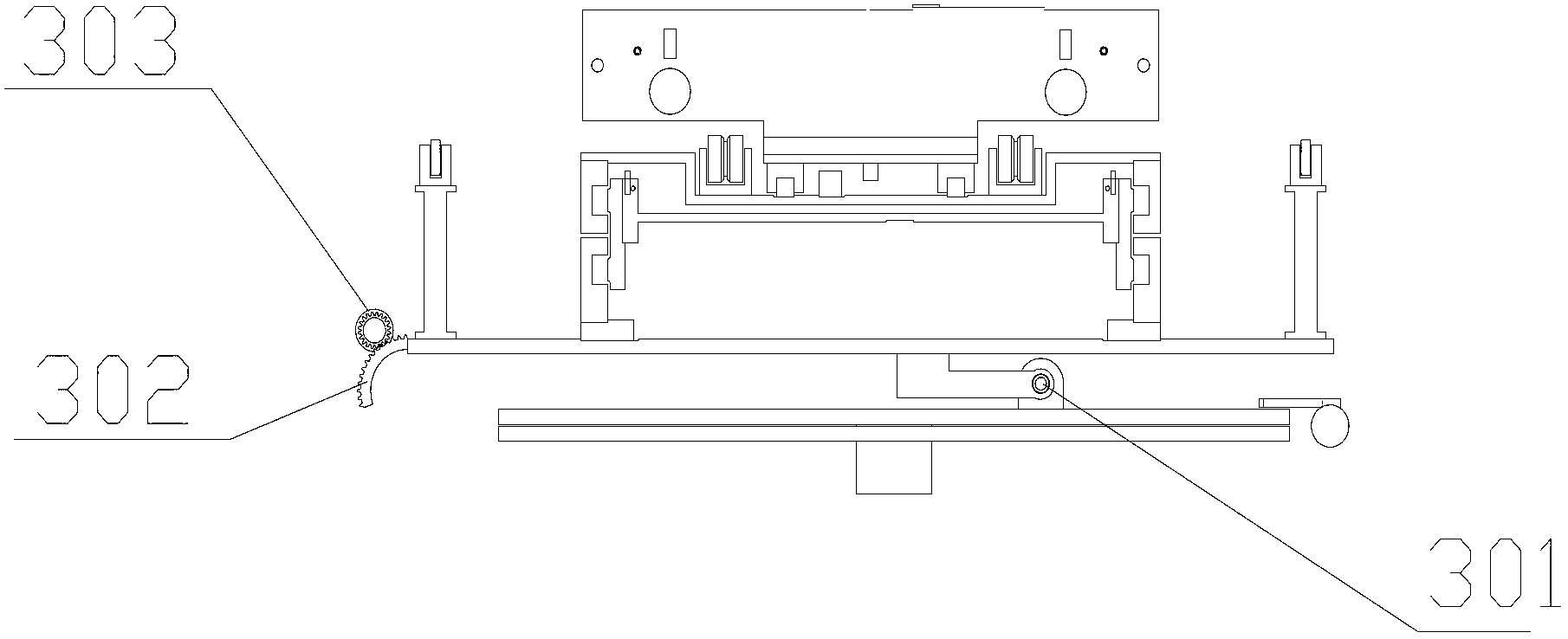

[0051] figure 1 , figure 2 The figure shows the schematic diagram of the rear view structure of the battery replacement robot and the loading platform unit of the present invention. In the figure, the mechanical part of the system is provided with a horizontal movement unit 107, a loading platform unit and a load-bearing unit, thus establishing the three-coordinate main structure of the system. The horizontal moving unit 107 includes rollers and follower rollers with rims on both sides, a ground rail 105 connected to the lower beam 104 of the load-bearing unit, and the end of the ground rail 105 is provided with a limit bumper 106, and the rollers and The follower roller is connected with the motor reducer, and the motor reducer is connected with the lower beam 104 of the load-bearing unit. The load-bearing unit is arranged on the top of the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com