Method for separating heavy metals lead and cadmium by using biological adsorbent packed column

A biosorbent and packed column technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor adsorption selectivity, low adsorption capacity, and limited application of biosorbents, etc. problems, to achieve the effect of large adsorption capacity, simple production method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

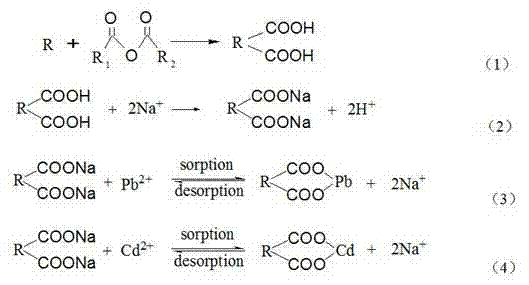

[0018] 1. Prepare the biosorbent packed column of the present invention: add 15.0 g of pyromellitic dianhydride to 500 mL of N,N-dimethylformamide, ultrasonically dissolve it under airtight conditions, add 10.0 g of it after drying The crushed corn stalks were reacted at 70°C for 4 h and then centrifuged. The product was washed several times with deionized water and 0.1 mol / L NaOH solution. After centrifugation, the product was dried in an oven at 60°C for 12 h to obtain hydroxyl surface-modified corn. straw. 1.5 g of hydroxyl surface-modified corn stalks were filled into a chromatographic column (inner diameter 1.0 cm, length 20 cm) by wet packing method to make an adsorption packed column.

Embodiment 2

[0023] 1. Prepare the biosorbent packed column of the present invention: add 15.0 g of pyromellitic dianhydride into 500 mL of N,N dimethylformamide, dissolve it ultrasonically under airtight conditions, add 10.0 g after it is completely dissolved, and dry and pulverize The corn stalks were reacted at 70°C for 4 h and then centrifuged. The product was washed several times with deionized water and 0.1 mol / L NaOH solution. After centrifugation, the product was dried in an oven at 60°C for 12 h to obtain modified corn stalks. 3.0 g of modified corn stalks were packed into a chromatographic column (inner diameter 1.5 cm, length 30 cm) by wet packing method to make an adsorption packed column.

[0024] 2. Application example: biosorbent packed column for Pb 2+ 、Cd 2+ adsorption separation

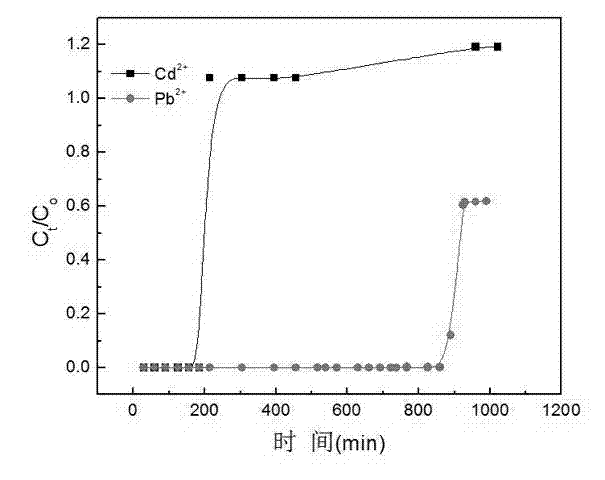

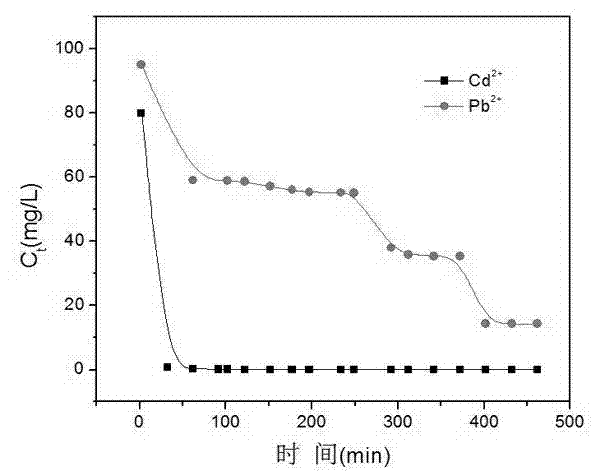

[0025] Configured with Pb 2+ 200 mg / L, Cd 2+ 100 mg / L of simulated wastewater was counter-flowed into the packed column through a peristaltic pump at room temperature. The chromatographic...

Embodiment 3

[0027] 1. Prepare the biosorbent packed column of the present invention: add 15.0 g of ethylenediaminetetraacetic acid dianhydride to 500 mL of N, N dimethylformamide, ultrasonically dissolve it under airtight conditions, add 10.0 g of it after drying The crushed corn stalks were reacted at 70°C for 4 h and then centrifuged. The product was washed several times with deionized water and 0.1 mol / L NaOH solution. After centrifugation, the product was dried in an oven at 60°C for 12 h to obtain modified corn stalks. 4.0 g of modified corn stalks were filled into a chromatographic column (inner diameter 2 cm, length 30 cm) by wet packing method to make an adsorption packed column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com