Technology for producing ammonium sulfate fertilizer through desulfurizing smoke by ammonia process, and apparatus thereof

A flue gas and ammonium sulfate technology, which is applied to fertilization devices, ammonium salt fertilizers, nitrogen fertilizers, etc., can solve the problems of low equipment failure rate, large ammonium sulfate particles, and large steam energy consumption, so as to reduce wear and corrosion, and particle size The effect of uniform distribution and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

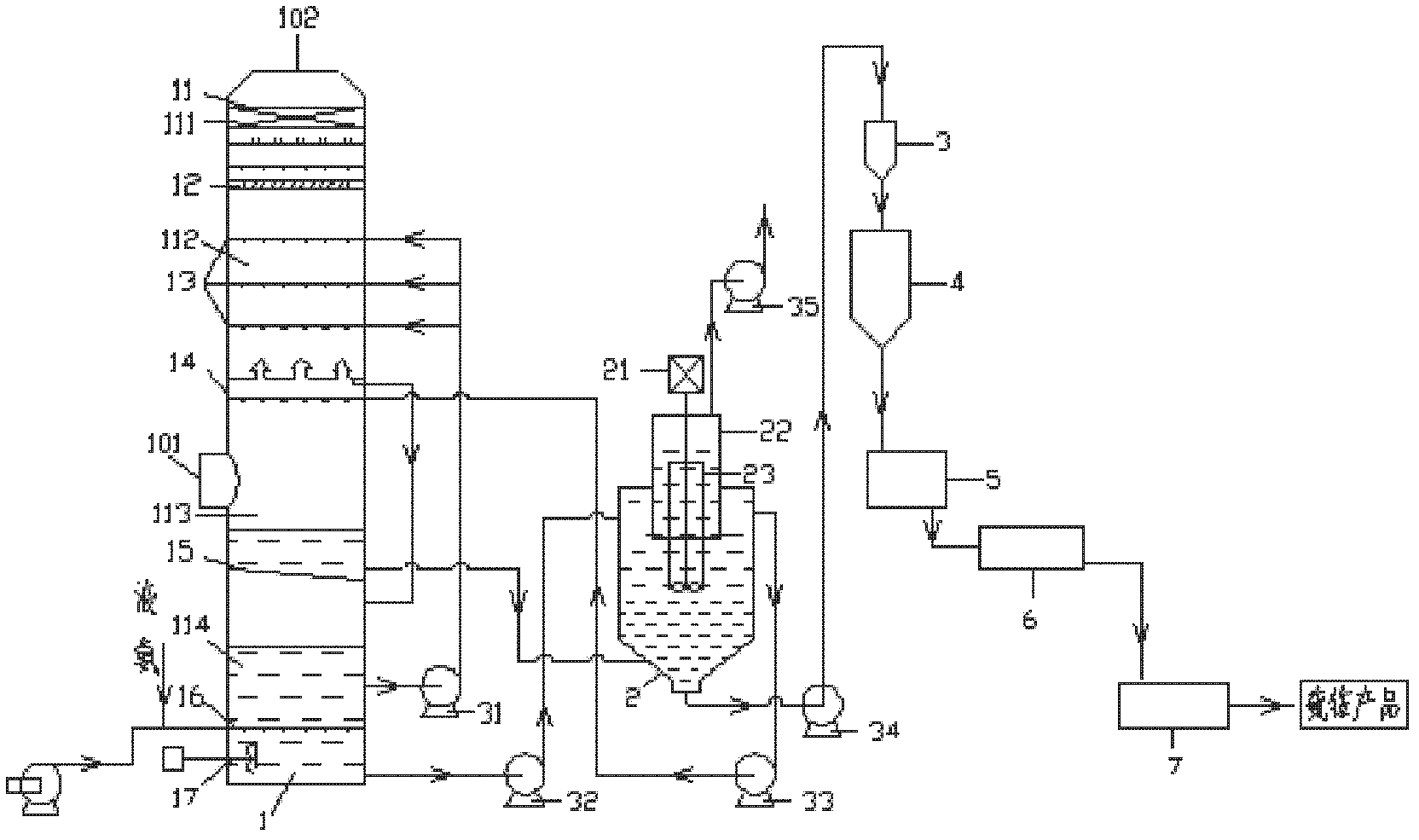

[0028] 2 sets of 130t / h coal-fired boilers, the sulfur content of the coal used is 1.6%, and the flue gas flow rate is 280000Nm 3 / h, SO 2 The content is 2600mg / Nm 3 , the dust content of the flue gas is 50mg / Nm3, and the flue gas temperature is 132°C;

[0029] The diameter of the desulfurization tower is 7m and the height is 40m. The tower body is made of carbon steel lined with glass flakes, and the thickness of the tower body ranges from 8mm to 16mm. , the material of the spray layer is FRP, and the liquid distributor adopts sic spiral nozzle; there is a layer of grid packing layer between the absorption section and the defogging section, and the height of the packing layer is 1.5m; the evaporation crystallization section is equipped with a first-level spray layer, FRP material, the liquid distributor is a sic spiral nozzle; the height of the oxidation section is 12m;

[0030] After the flue gas enters the desulfurization tower, in the evaporation and crystallization sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com