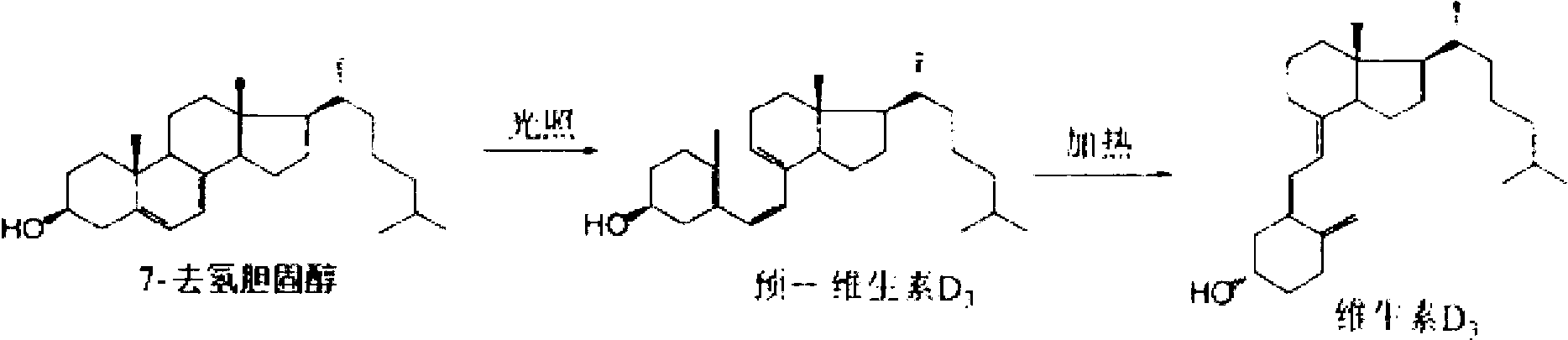

Technology for preparing vitamin D3

A vitamin and process technology, applied in the field of preparation technology of pure vitamin D3, can solve the problems of low separation yield and difficult separation, and achieve the effects of simple process, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 1kg of 7-dehydrocholesterol with a content of 95% at a concentration of 3wt.% in 22L methanol + 11L n-hexane at 40°C to make a 7-dehydrocholesterol solution, and turn on the photochemical water cooler, nitrogen, and circulating water pump , High-pressure mercury lamp, turn on the magnetic pump to pass the 7-dehydrocholesterol solution into the photochemical reactor, control the reaction temperature to 40°C, carry out the photochemical reaction at a flow rate of 0.5L / min, collect the photochemical reaction solution to detect the conversion rate of 14%, and perform decompression Recover n-hexane and methanol, control the temperature at about 30°C to distill 80%, and centrifuge to obtain 0.75 kg of 7-dehydrocholesterol, which is used again. The filtrate is stirred and frozen at -10°C for 10 hours, and then filtered to obtain Contain the solution of a large amount of vitamin P3, the filtrate is all reclaimed, obtain the oily solid containing 75% vitamin P3, 5% vitam...

Embodiment 2

[0020] 750 grams of 7-dehydrocholesterol recovered from Example 1 + 250 grams of 95% fresh 7-DHC were dissolved in 22L methanol + 11L n-hexane at a temperature of 45°C at a concentration of 3% to prepare 7-dehydrocholesterol solution, turn on the photochemical water cooler, nitrogen, circulating water pump, and high-pressure mercury lamp, turn on the magnetic pump to pass the 7-dehydrocholesterol solution into the photochemical reactor, control the reaction temperature at 45°C, and carry out the photochemical reaction at a flow rate of 0.6L / min. For the reaction solution, first detect the conversion rate of 12%. After the detection, recover methanol and n-hexane. Control the temperature at about 30°C to recover 75% of methanol and n-hexane. After centrifugation, 0.7 kg of 7-dehydrocholesterol is obtained. Apply mechanically for the first time, the filtrate was frozen and crystallized at -10°C for 8 hours, and then filtered to obtain a solution containing a large amount of vitam...

Embodiment 3

[0022] 750 grams of 7-dehydrocholesterol recovered from Example 2 + 250 grams of 95% fresh 7-DHC were dissolved in 22L methanol + 11L n-hexane at a temperature of 45°C at a concentration of 3% to prepare 7-dehydrocholesterol solution, turn on the photochemical water cooler, nitrogen, circulating water pump, and high-pressure mercury lamp, turn on the magnetic pump to pass the 7-dehydrocholesterol solution into the photochemical reactor, control the reaction temperature at 45°C, and carry out the photochemical reaction at a flow rate of 0.6L / min. For the reaction solution, first detect the conversion rate of 12%. After the detection, recover methanol and n-hexane. Control the temperature at about 30°C to recover 75% of methanol and n-hexane. After centrifugation, 0.7 kg of 7-dehydrocholesterol is obtained. For the first time, the filtrate was frozen and crystallized at -10°C for 8 hours, and then filtered to obtain a solution containing a large amount of vitamin P3. The filtrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com