Polyamic acid resin and polyimide resin purification method

A technology of polyamic acid resin and polyimide resin, which is applied in the field of purification of resin solution, and can solve problems such as complex process procedures and large amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

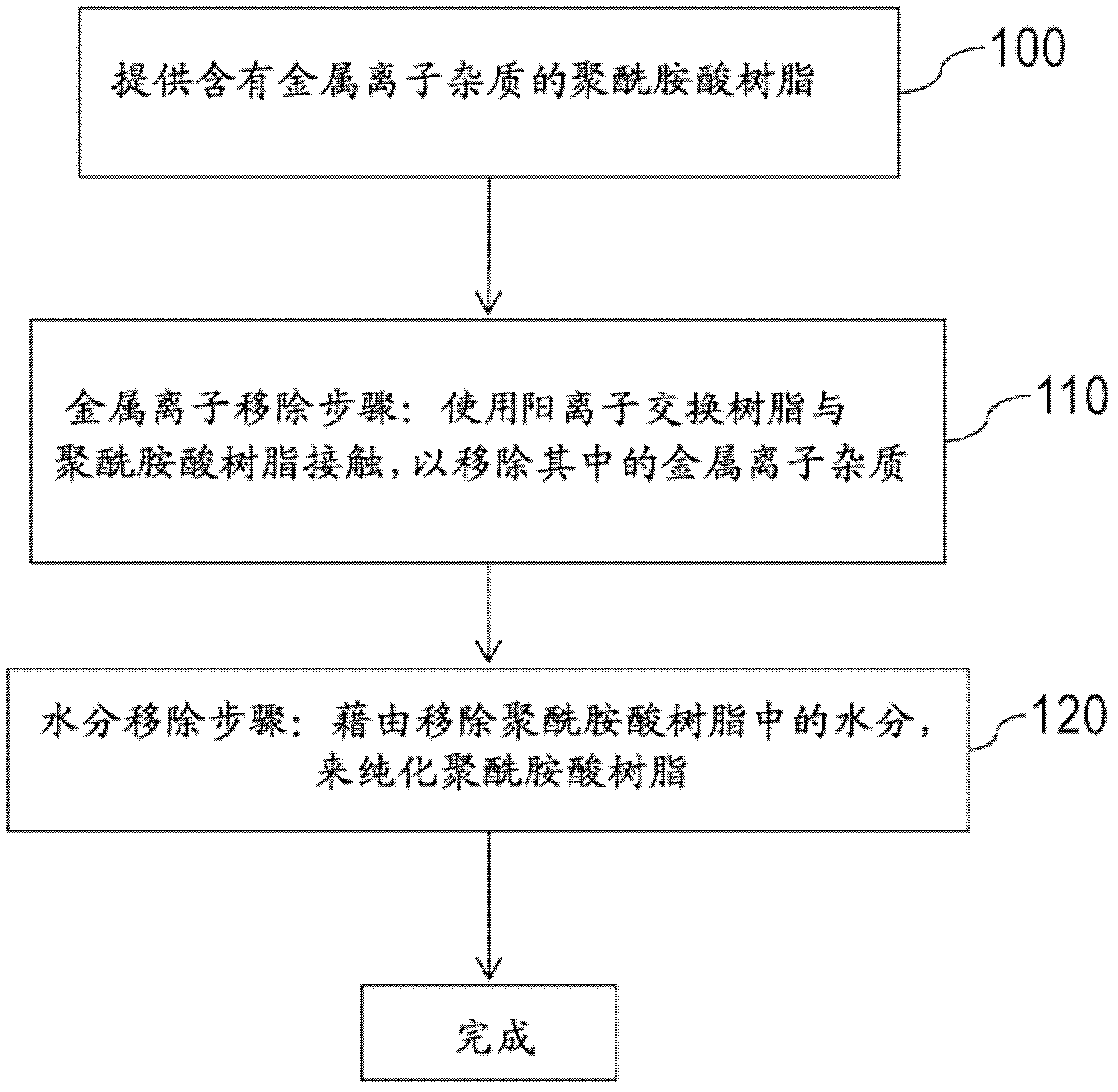

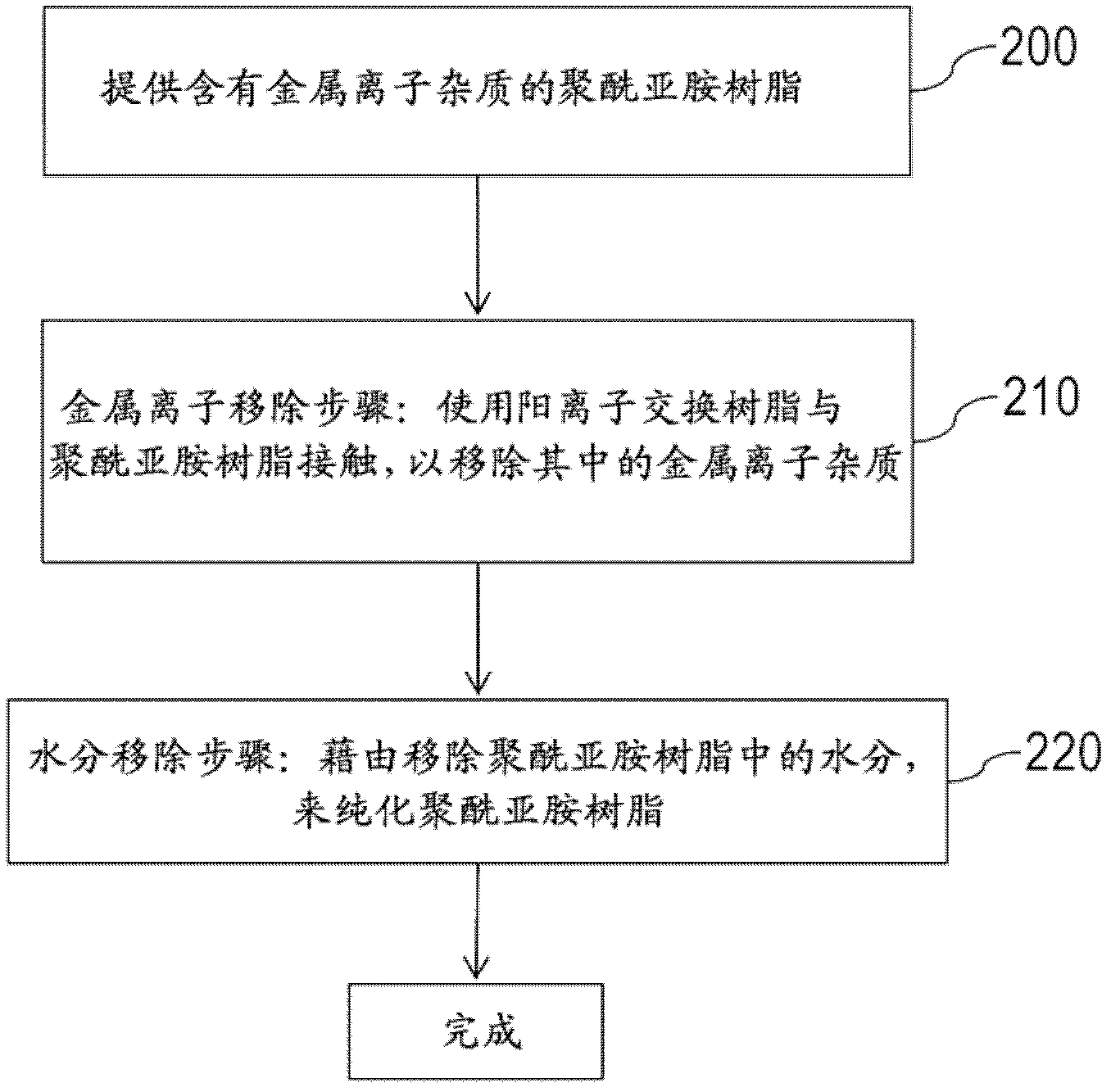

Method used

Image

Examples

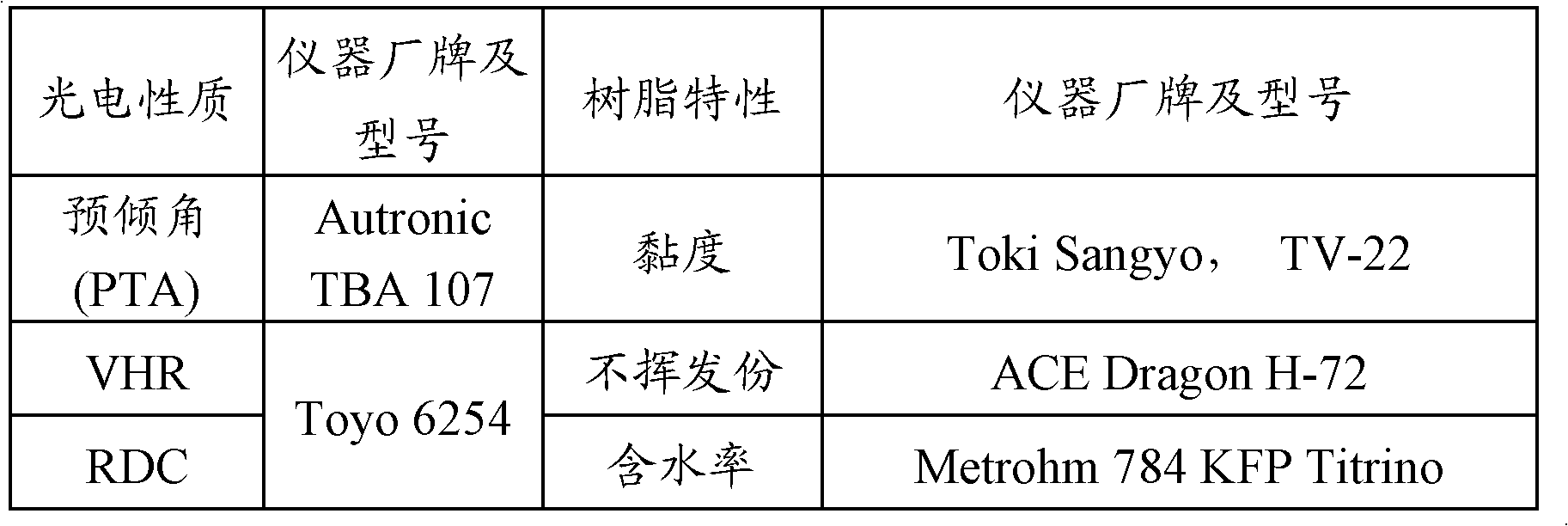

experiment example 1

[0044] Firstly, PI resin (or PAA resin) containing metal ion impurities and ion exchange resin ( 50W series; Monosphere series; Marathon; series; series) for mixing, the usage ratio is 1wt% ~ 50wt% relative weight ratio, and stir evenly at 15°C ~ 20°C so that the PI resin can be fully mixed with the ion exchange resin, and then 2kg / m 2 The inert gas pushes the liquid through a 300 mesh (mesh) filter plate to separate the ion exchange resin and PI resin, and then add the PI resin to the reaction kettle for vacuum distillation at 15 ° C ~ 65 ° C / 0.1 Torr ~ 5 Torr , Take a sample every 4 hours to detect the moisture content until the moisture content reaches below 0.1%.

experiment example 2

[0046] Firstly, PI resin (or PAA resin) containing metal ion impurities and ion exchange resin ( 50W series; Monosphere series; Marathon; series; series) for mixing, the usage ratio is 50wt%-80wt% relative weight ratio, and mix at 20°C-25°C, stir evenly so that the PI resin can be fully mixed with the ion exchange resin, and then use 2kg / m 2 The inert gas pushes the liquid through a 300 mesh (mesh) filter plate to separate the ion exchange resin and PI resin, and then add the PI resin to a thin film evaporator at 150rpm with a speed of 0°C to 65°C / 0.01 torr to 2 torr Concentrate, and check the water content every time it passes through the device and takes a sample. If it does not meet the specification, it will be repeatedly fed into the thin film evaporator until the water content reaches below 0.1%.

experiment example 3

[0048] The ion exchange resin ( 50W series; Monosphere series; Marathon; series; series) mixed and filled at 20℃~25℃ to the bottom of the pressure vessel supported by a 300-mesh filter plate, and the PI resin containing metal ion impurities was mixed at 2kg / m 2 ~4kg / m 2 Nitrogen is transported through the packed tower and fully mixed with the ion exchange resin at a flow rate of 30L / h~120L / h, and then the PI resin (or PAA resin) is added to the reactor at 15°C~65°C / 0.1 Torr~5 Torr Vacuum distillation, sampling once every 4 hours for moisture content testing until the moisture content reaches below 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com