Method for assembling gold and silver one-dimensional nano-material by adopting electrostatic spinning technology and application thereof

An electrospinning technology and nanomaterial technology, which is applied in the field of preparation of electrospinning and assembling gold and silver one-dimensional nanomaterials, can solve the problems of cumbersome surface treatment steps, and achieve the effects of fast assembly, good flexibility and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

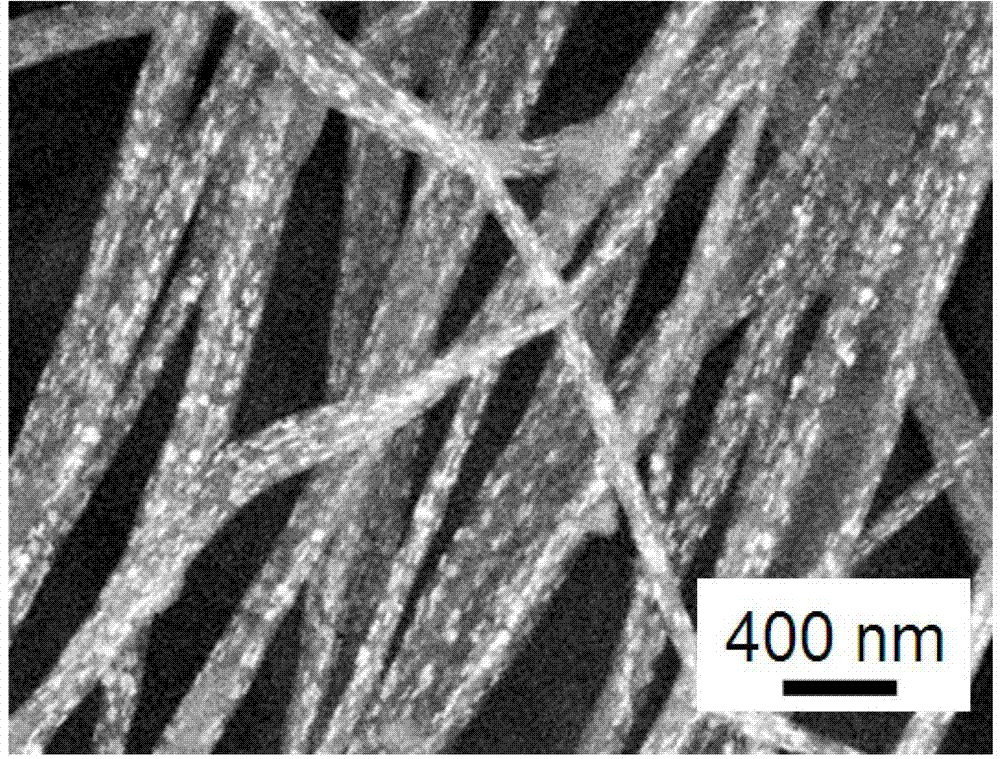

[0043]Wash and centrifuge the prepared gold nanorods (length: 78±6nm; width: 19±1nm) with deionized water (8000rpm, 6min) to finally obtain an aqueous solution with a particle concentration of gold nanorods of 4mg / mL, and add Polyvinyl alcohol, so that the volume concentration of the polymer is 9%, magnetically stirred for 4 hours, and the rotation speed is 200rpm, so that the polymer is completely dissolved, and this solution is used as an electrospinning solution. Transfer the electrospinning solution into a 10 mL syringe for electrospinning. The flow rate was set to 0.08mL / h, the voltage was 9KV, and the distance from the needle to the receiving screen was 10cm. Electrospun films containing gold nanorods can be obtained after electrospinning for 1 h.

[0044] The electrospun membrane can be separated from the receiving screen to obtain a self-supporting film. In addition, electrospinning for 1 hour can obtain an area of more than 30cm 2 The thin film proves that electr...

Embodiment 2

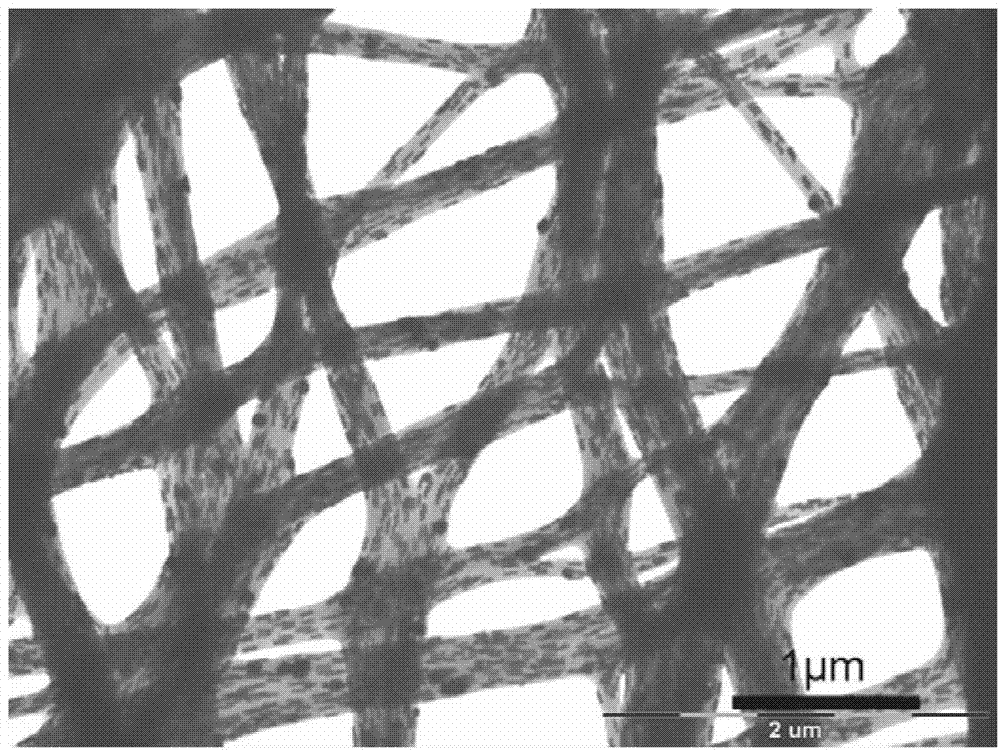

[0048] Wash and centrifuge the prepared silver nanowires (10-20 μm in length and 30-40 nm in diameter) with ethanol (4000 rpm, 5 min) to obtain an ethanol solution with a mass concentration of silver nanowires of 20 mg / mL, and add polyvinylpyrrolidone to the solution , so that the volume concentration of the polymer is 10%, magnetically stirred for 3 hours, and the rotation speed is 300rpm, so that the polymer is completely dissolved, and this solution is used as an electrospinning solution. Transfer the electrospinning solution into a 10 mL syringe for electrospinning. The flow rate was set to 1.2mL / h, the voltage was 10KV, and the distance from the needle to the receiving screen was 10cm. The electrospun membrane containing silver nanowires can be obtained after electrospinning for 30 min.

[0049] The electrospun membrane can be separated from the receiving screen to obtain a self-supporting film. In addition, electrospinning for 15 minutes can obtain an area of more th...

Embodiment 3

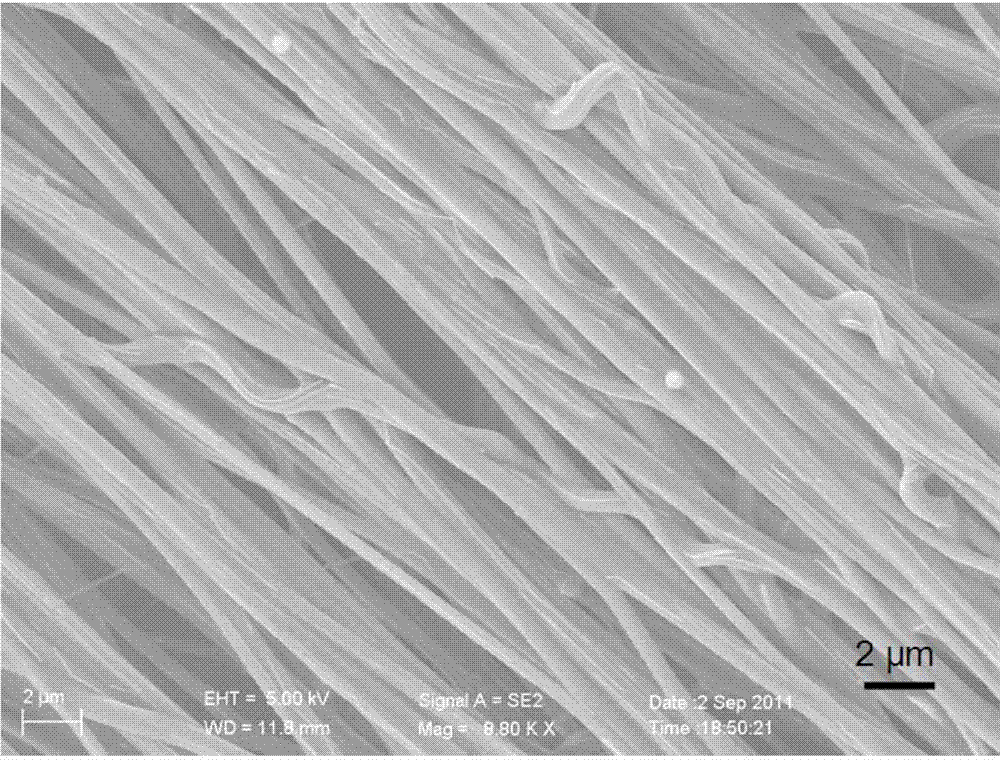

[0052] Add 16 mg of silver nanowires (10-20 μm in length, 30-40 nm in diameter) into a certain volume of prepared gold nanorod solution, stir overnight, centrifuge (10000 rpm, 5 min), wash once with deionized water, and finally get Gold nanorod-silver nanowire assembly, wherein the mass concentration of gold nanorods is 4mg / mL, the mass concentration of silver nanowires is 5mg / mL, polyvinyl alcohol is added to the solution, so that the volume concentration of the polymer is 6%, the magnetic force Stir for 4 hours at a rotational speed of 300 rpm to completely dissolve the polymer, and this solution is used as an electrospinning solution. Transfer the electrospinning solution into a 10 mL syringe for electrospinning. The flow rate was set to 0.1mL / h, the voltage was 7KV, and the distance from the needle to the receiving screen was 12cm. Electrospun membranes containing gold nanorods-silver nanowire assemblies can be obtained after electrospinning for 1 h.

[0053] The electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com